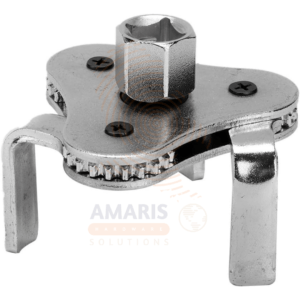

MECHANICAL PARTS & SPARES

Y Type Wrench – Long {8mm,9mm,10mm} (12 pieces)

Whatsapp Order

A “Long Y Type Wrench” is a tool used for turning bolts, nuts, or other fasteners.

- Long:

- Indicates that the wrench has an extended or elongated design compared to standard wrenches. The added length can provide increased leverage, making it useful for applications where more torque is required or for accessing fasteners in hard-to-reach places.

- Y Type:

- Refers to the shape of the handle, resembling the letter Y. The Y-shaped handle design is often chosen for ergonomic reasons, offering a comfortable and secure grip while allowing for effective application of torque.

1. Socket material: 40Cr

2. Y-handle material: Carbon steel #45

3. Torque capacity: 8mm/33N.M

10mm/58.1N.M 12mm/89.1N.M

4. Chrome mated

KSh 6,980.00 KSh 7,480.00

Y type wrench uses

- Increased Leverage:

- The extended length of the wrench provides increased leverage. This is particularly useful when dealing with stubborn or tight fasteners, allowing the user to apply more torque with less effort.

- Hard-to-Reach Areas:

- The longer reach of the wrench makes it suitable for accessing fasteners in confined or difficult-to-reach spaces. This is advantageous in automotive repair, machinery maintenance, and other applications where standard-length wrenches might not be effective.

- Torqueing Bolts and Nuts:

- Long Y Type Wrenches are commonly used for tightening or loosening bolts and nuts in various applications, such as construction, automotive repairs, or industrial maintenance.

- Ergonomic Handling:

- The Y-shaped handle design provides an ergonomic grip, making the wrench comfortable to use for extended periods. This feature is beneficial for reducing hand fatigue and improving overall user comfort.

- Versatility in Applications:

- The combination of a long length and Y-shaped handle design makes this type of wrench versatile. It can be used in a range of applications across different industries, from plumbing and electrical work to mechanical repairs.

- Assembly and Disassembly:

- The wrench is useful in assembly and disassembly tasks where proper torque is crucial. The extended length allows for controlled and precise application of force.

- Heavy-Duty Tasks:

- The added leverage and strength make long Y Type Wrenches suitable for heavy-duty tasks, including applications in construction, manufacturing, and industrial settings.

- Maintenance and Repair Work:

- Mechanics and technicians often use long Y Type Wrenches during maintenance and repair work on vehicles, machinery, and equipment.

size

8mm,9mm,10mm,11mm,12mm,13mm,14mm,17m

Safety Precautions

- Wear Personal Protective Equipment (PPE):

- Use appropriate personal protective equipment, such as safety glasses, gloves, and other gear, depending on the specific task and potential hazards.

- Inspect the Wrench:

- Before use, inspect the wrench for any damage, wear, or defects. Ensure that the handle and head are securely attached. Do not use a damaged or compromised wrench.

- Choose the Right Size:

- Use the correct size of the wrench for the fastener you are working on. Using an improperly sized wrench may result in slippage and injuries.

- Apply Even Pressure:

- Apply force evenly and steadily when using the wrench. Avoid sudden or jerky movements, as these can lead to loss of control.

- Position Yourself Properly:

- Stand in a stable and balanced position. Keep your feet shoulder-width apart for better stability. Avoid awkward positions that may compromise your balance.

- Be Mindful of Surroundings:

- Be aware of your surroundings and ensure there are no obstacles or tripping hazards in your work area. Keep bystanders at a safe distance.

- Use Correct Technique:

- Use the proper technique for turning the wrench, especially when dealing with tight fasteners. Push or pull the handle in the direction that allows for the most efficient use of force.

- Avoid Excessive Force:

- Do not apply excessive force that goes beyond the wrench’s capacity. If a fastener is too tight, consider using additional tools or methods, or seek assistance.

- Secure the Workpiece:

- Ensure the workpiece is properly secured before applying force. This prevents unexpected movement or slipping, reducing the risk of accidents.

- Store Properly:

- When not in use, store the wrench in a safe and designated location. Avoid leaving tools in areas where they can pose a tripping hazard.

- Follow Manufacturer’s Recommendations:

- Adhere to the manufacturer’s guidelines and recommendations for the specific wrench model. This includes information on its proper use, maintenance, and limitations.

- Training and Familiarity:

Ensure that users are adequately trained and familiar with the tool. Knowing how to use the wrench correctly can prevent accidents

Salome Godi –

Exceeded my expectations. Very satisfied.

Salome Godi –

Angela Marie –

Great value for the quality.

Angela Marie –