Angle Grinder Spanner

$3,700.00 Original price was: $3,700.00.$3,200.00Current price is: $3,200.00.

Angle Grinder

$7,750.00 Original price was: $7,750.00.$6,750.00Current price is: $6,750.00.

Angle Grinder Wrench

$3,700.00 Original price was: $3,700.00.$3,200.00Current price is: $3,200.00.

WhatsApp Order

An angle grinder wrench is a specialized tool designed to tighten or loosen the nut that secures the grinding wheel or cutting disc on an angle grinder. It typically has a handle or lever for easy gripping and a head with a shape that fits the nut on the grinder spindle. The primary purpose of the angle grinder wrench is to facilitate the installation, removal, or replacement of abrasive discs or accessories on the angle grinder, ensuring proper and secure attachment for safe and effective operation of the tool.

SKU:

AHS54326

Category: Power Tool Accessories

Description

Angle Grinder Wrench Uses

1.Changing Abrasive Discs:

-

- The most frequent use of the angle grinder wrench is for changing abrasive discs or cutting wheels on the angle grinder. It helps in loosening and tightening the nut that secures these accessories in place.

- Replacing Grinding Wheels:

- When a grinding wheel becomes worn or damaged, the angle grinder wrench is essential for removing the old wheel and installing a new one. This is crucial for maintaining the tool’s effectiveness and safety.

- Adjusting Accessories:

- Angle grinders can be used for various tasks by attaching different accessories, such as wire brushes, polishing pads, or sanding discs. The wrench is used to secure these accessories onto the grinder.

- Routine Maintenance:

- Periodic maintenance of the angle grinder, which may involve disassembling parts for cleaning or lubrication, often requires the use of the wrench to access internal components.

- Repairing or Replacing Parts:

- In case of damage or malfunction, the wrench is employed to disassemble the angle grinder for repairing or replacing specific parts, such as the spindle, gear assembly, or other components.

- Tightening or Loosening Bolts:

- Some angle grinders have additional features or accessories that may require bolts to be tightened or loosened. The wrench is useful for these tasks, ensuring that all parts are securely fastened.

- Adjusting Guard Positions:

- Angle grinders often come with adjustable safety guards. The wrench may be needed to adjust the position of the guard, providing protection and ensuring safe operation during different tasks.

- Securing Flanges:

- The wrench is used to secure or adjust the flanges that hold the grinding wheel in place. Properly tightened flanges are crucial for the stability and safety of the grinder.

Reviews (0)

Be the first to review “Angle Grinder Wrench” Cancel reply

Related products

5 pcs Glass Drill Set Hexagonal Handle

A 5-piece glass drill set with hexagonal handles typically refers to a collection of five drill bits specifically designed for drilling holes in glass surfaces. The term "hexagonal handle" indicates that the shank of each drill bit has a hexagonal (six-sided) shape, which can provide a better grip and prevent slipping when used with a compatible drill. These drill bits are specifically crafted for working with glass materials, offering precision and minimizing the risk of cracking or damaging the glass during the drilling process. The set may include different-sized bits to accommodate various hole diameters.

5 pcs Glass Drill Set Straight Handle

A 5 pcs Glass Drill Set with straight handle refers to a set of five drill bits specifically designed for drilling into glass surfaces. Each drill bit in the set typically has a straight handle, making it easier to grip and control during the drilling process. These drill bits are crafted with materials and designs that enhance their ability to cut through glass without causing cracks or shattering. The set may include a variety of drill bit sizes to accommodate different drilling needs and applications on glass surfaces

5 pcs Wood Drills Set Metric

A 5pcs Wood Drills Set - Metric refers to a collection of five wood drill bits designed for use in woodworking applications, with each drill bit sized according to the metric system. The set typically includes five different drill bits, each with a distinct diameter, allowing users to drill holes of varying sizes in wood materials. The metric measurement indicates that the sizes of the drill bits are specified in the metric system, which is based on units such as millimeters. This type of drill set is commonly used by carpenters, woodworkers, and DIY enthusiasts for precision drilling in wood.

5 Piece Jig Saw Blade Set

A 5-piece jig saw blade set typically refers to a collection of five individual blades designed for use with a jigsaw, which is a versatile power tool used for cutting various materials, such as wood, metal, plastic, and more. These blade sets often come with different blade types, each optimized for specific materials or cutting tasks. The set may include blades with varying tooth configurations, sizes, and materials to accommodate a range of cutting needs. The purpose of providing multiple blades is to offer users flexibility and adaptability when tackling different projects or materials with their jigsaw.

9 pcs Mixed Drill Set – Metric

A 9 PCS Mixed Drill Set - Metric typically refers to a set of nine drill bits with various sizes and types, all measured in the metric system. The set may include a variety of drill bit sizes commonly used for different purposes, such as drilling holes in metal, wood, plastic, or other materials. The term "mixed" indicates that the set contains a combination of drill bits with different characteristics, such as varying diameters or types of tips, providing versatility for different drilling applications.

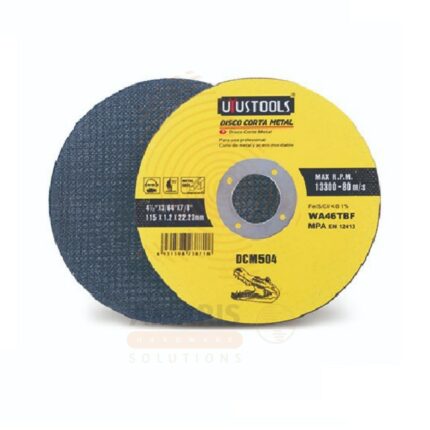

Cutting Wheel Thin

A cutting wheel, specifically a thin cutting wheel, is a specialized abrasive tool designed for precision cutting in various materials such as metal, plastic, or stone. It typically consists of a thin, flat, circular disc made of abrasive material bonded with resin or other substances. The thin profile of the cutting wheel allows for narrow cuts and reduces material wastage. These wheels are commonly used with angle grinders or rotary tools and are employed in applications ranging from metal fabrication and construction to DIY projects.

Cymbal Type Flap Disc

A "Cymbal Type Flap Disc" refers to a specific design of flap disc used in metalworking and grinding applications. The term "cymbal" in this context likely to the shape or configuration of the flap disc, resembling the round, concave form of a cymbal used in percussion instruments.

A Cymbal Type Flap Disc features abrasive flaps arranged in a circular pattern around a central hub, similar to how the surfaces of a cymbal are arranged in a circular fashion. These abrasive flaps are made of coated abrasive material and are used for grinding, blending, and finishing metal surfaces.

The design of the Cymbal Type Flap Disc allows for efficient material removal and provides a smooth finish on various metal surfaces. The arrangement of the flaps ensures that the abrasive material wears evenly during use, prolonging the life of the disc and maintaining consistent performance.

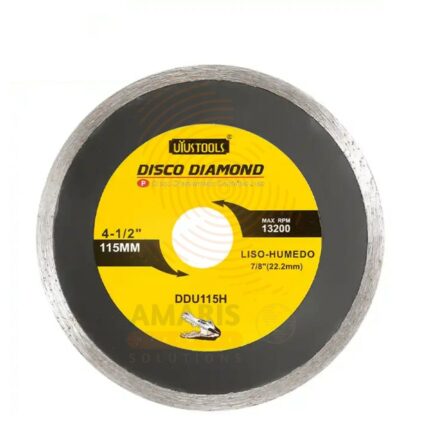

Diamond Cutting Blade(Wet) – Cold Press 12 pieces

A diamond cutting blade (wet) – cold press refers to a specialized tool used for cutting hard materials such as stone, concrete, or ceramic tiles. The term "diamond" in this context refers to the use of industrial-grade diamonds embedded on the blade's edge, which provides exceptional hardness and abrasion resistance. The cutting process is typically done with water to cool the blade and minimize dust. The "cold press" aspect suggests that the cutting is performed without the application of excessive heat, ensuring precision and preventing damage to the material being cut. This type of cutting blade is commonly used in construction and masonry for achieving accurate and clean cuts in tough materials.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins

Reviews

There are no reviews yet.