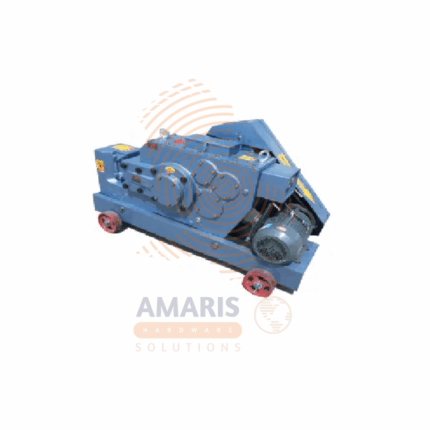

Reinforcing Bar Bending Machine

WhatsApp Order

A reinforcing bar bending machine is a specialized tool used in construction and civil engineering to bend steel reinforcement bars (rebar) accurately and efficiently according to specific project requirements. These machines typically consist of a sturdy frame, bending mechanism, and controls. They are designed to handle various sizes and shapes of rebar’s and can bend them to precise angles and configurations needed for reinforcing concrete structures such as beams, columns, and foundations. The primary purpose of these machines is to streamline the bending process, increase productivity, and ensure the structural integrity of reinforced concrete elements in construction projects

SKU:

AHS34882

Category: Power Tool Accessories (Blades, Bits, Discs)

Description

Reinforcing Bar Bending Machine Uses

- Construction of reinforced concrete structures: Reinforcing bar bending machines are extensively used in the construction of reinforced concrete structures such as buildings, bridges, dams, tunnels, and roads. These machines enable the precise bending of rebar’s to create the framework necessary to reinforce concrete elements, ensuring structural stability and strength.

- Building foundations and footings: In the construction of building foundations and footings, reinforcing bar bending machines are used to bend rebar’s into specific shapes and configurations required to provide adequate support and reinforcement for the foundation structure.

- Structural beams and columns: Reinforcing bar bending machines are employed to bend rebar into various shapes and angles to form structural beams and columns. These elements play a crucial role in supporting the weight of the building and transferring loads to the foundation.

- Retaining walls and slabs: Reinforcing bar bending machines are utilized to bend rebar into the desired shapes for constructing retaining walls and slabs. These structures provide stability and prevent soil erosion in areas where the ground needs to be retained or supported.

- Reinforced concrete walls and floors: In the construction of reinforced concrete walls and floors, reinforcing bar bending machines are used to bend rebar to the required specifications for reinforcing these elements. This reinforcement enhances the structural integrity and load-bearing capacity of the walls and floors.

- Infrastructure projects: Reinforcing bar bending machines play a crucial role in various infrastructure projects such as the construction of highways, railways, airports, and ports. They are used to bend rebar’s for constructing structures like retaining walls, abutments, piers, and other components essential for infrastructure development.

- Pre-cast concrete elements: In pre-cast concrete manufacturing facilities, reinforcing bar bending machines are utilized to bend rebar’s according to the design requirements of pre-cast concrete elements such as beams, columns, panels, and slabs. This ensures precision and consistency in the fabrication process.

Reviews (0)

Be the first to review “Reinforcing Bar Bending Machine” Cancel reply

Related products

5 Piece Jig Saw Blade Set

The 5 Piece Jig Saw Blade Set is a versatile collection of blades designed for cutting various materials with a jigsaw. It typically includes different blade types with varying tooth counts for smooth or aggressive cuts. Ideal for DIYers and professionals, this set ensures compatibility with most standard jigsaws and provides options for precise, clean cuts in wood, plastic, or metal.

Flat Knotted Wire Wheel

A flat knotted wire wheel refers to a rotating tool used in various applications, typically in metalworking and surface preparation. It consists of a wheel-shaped assembly with wire bristles that are tightly twisted or "knotted" together. The wire bristles can be made of steel or other durable materials, and they are arranged in a radial pattern around the wheel.

Knotted wire wheels are commonly attached to power tools such as angle grinders or bench grinders. They are employed for tasks like removing rust, paint, scale, or other surface contaminants from metal surfaces, as well as for deburring or blending welds. The tightly twisted configuration of the wire bristles enhances the wheel's durability and effectiveness in tackling tough materials and applications.

These wheels are available in various sizes and designs to suit different tasks, and they are known for their abrasive action, making them valuable tools in metal fabrication, construction, and maintenance work.

Prescott Guide Bar for chain saw

A guide bar for chain saw is a straight or slightly curved, elongated metal component that serves as a support structure for the saw chain. It is an essential part of the chainsaw's cutting system and typically extends from the chainsaw's body, providing a stable platform for the rotating chain. The guide bar features a groove along its length, which accommodates the cutting teeth of the chainsaw chain, guiding it in a straight line during operation. The length of the guide bar determines the maximum diameter of the wood that can be cut by the chainsaw. Additionally, guide bars may incorporate features such as a sprocket tip or a replaceable nose to enhance performance and extend the life of the bar.

SDS Plus Stone Flat Chisel

An SDS-PLUS stone flat chisel is a specialized tool designed for use with SDS-PLUS rotary hammer drills. It is a flat-edged chisel specifically crafted for masonry and stone applications. The SDS-PLUS shank refers to the type of chuck connection that allows for quick and secure tool changes in compatible rotary hammer drills. The flat chisel design is ideal for tasks such as chipping, carving, and shaping stone or masonry surfaces. This tool is commonly used in construction and renovation projects where precision and efficiency in working with hard materials are essential.

SDS Plus Stone Pointed Chisel

An SDS-PLUS stone pointed chisel is a specialized masonry tool designed for use with rotary hammer drills that feature the SDS-PLUS chuck system. This chisel has a pointed tip specifically crafted for effective and precise material removal in stonework, concrete, or similar hard surfaces. The SDS-PLUS system allows for quick and secure attachment of the chisel to the drill, ensuring efficient chiseling and reducing the likelihood of slippage during operation. The stone pointed chisel is commonly employed in tasks such as carving, shaping, or breaking hard materials in construction and masonry applications.

Velcro Sanding Disc

A Velcro sanding disc, also known as a hook and loop sanding disk, is an abrasive tool used in sanding and finishing applications. It features a backing pad with a surface covered in tiny hooks, and the sanding disk has a corresponding looped surface. The attachment system allows for quick and easy changes of sanding disks without the need for adhesives or tools. The Velcro-like connection provides a secure grip during sanding, ensuring efficient material removal and facilitating the smooth transition between different grits of sandpaper for various sanding tasks.

Wire Wheels with Shank for Drills

A wire wheels with shank for a drill is a rotating tool designed for use with a power drill. It consists of a wheel-shaped attachment made of wire bristles, often arranged in a circular pattern. The wheel is mounted on a shank, which can be securely attached to the chuck of a drill. This tool is commonly used for various applications, such as cleaning, deburring, and polishing surfaces, particularly metal surfaces. The wire bristles on the wheel help to remove rust, paint, corrosion, and other unwanted materials, making it a versatile tool for surface preparation in different industries and DIY projects. The shank allows easy attachment to the drill, enabling efficient and controlled use of the wire wheel for various tasks.

Wood Drills

A wood drill, commonly referred to as a wood drill bit or wood bit, is a cutting tool specifically designed for drilling holes in wood. These drill bits typically have a pointed tip for accurate positioning and a spiral groove or flutes along the shaft to remove wood chips and debris as the bit penetrates the material. Wood drills come in various sizes and types, such as twist drills, spade drills, or auger bits, each tailored for specific applications and hole sizes in woodworking projects.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins

Reviews

There are no reviews yet.