Cement and Paint Mixer

$17,750.00 Original price was: $17,750.00.$16,750.00Current price is: $16,750.00.

6 pcs Electrician Screwdriver Set

$17,600.00 Original price was: $17,600.00.$17,100.00Current price is: $17,100.00.

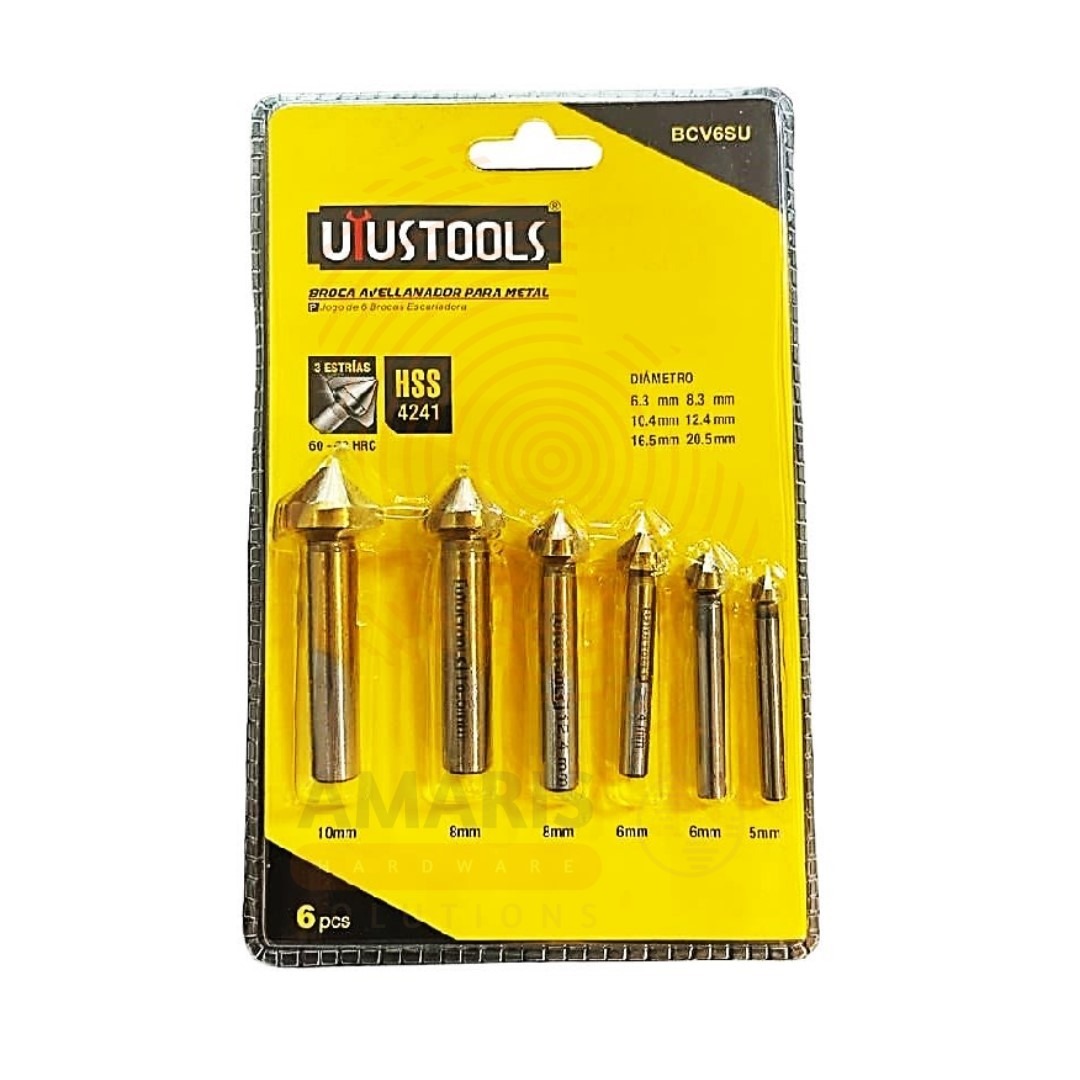

6 pcs Countersink Drill Set

$16,500.00 Original price was: $16,500.00.$16,000.00Current price is: $16,000.00.

WhatsApp Order

A 6 PCS countersink drill set typically refers to a collection of six tools designed for countersinking operations in woodworking or metalworking. Each set usually includes six individual countersink drills with varying sizes or angles. Countersinking is a process that involves creating a conical hole in a material, allowing the head of a screw or bolt to sit flush with or below the surface. These drill sets are essential for achieving a professional finish in various applications where a smooth and even surface is desired, such as in carpentry, metal fabrication, or DIY projects

SKU:

AHS72441

Category: Power Tool Accessories

Description

Countersink Drill Set Uses

- Woodworking: Countersink drill sets are commonly used in woodworking to create conical holes for embedding screws or bolts. This ensures a flush and smooth surface, preventing the protrusion of fastener heads.

- Metalworking: In metal fabrication, countersinking is crucial for applications where a flat and even surface is needed. This is common in the aerospace, automotive, and construction industries.

- Carpentry: Carpenters often use countersink drill sets to prepare wood surfaces for screw or nail installation. This helps in achieving a neat and professional finish, particularly when working with visible fasteners.

- Assembly and Joinery: Countersinking is essential in assembly and joinery work, where concealed fasteners are preferred for aesthetic reasons. It ensures that screws or bolts are recessed, maintaining a smooth appearance.

- DIY Projects: DIY enthusiasts commonly use countersink drill sets for various projects around the house, such as building furniture, installing shelves, or crafting wooden items. It allows for a clean and polished look in DIY creations.

- Metal and Plastic Fabrication: In addition to wood, countersink drill sets are also employed in metal and plastic fabrication to create chamfered holes for fasteners. This is crucial for applications where aesthetics and surface finish are important.

- Repair Work: When repairing or restoring items, countersinking is often required to ensure that new fasteners sit properly in the material without causing uneven surfaces.

- Boatbuilding: In boat construction, countersink drill sets are used to prepare surfaces for fasteners without compromising the integrity of the material, helping maintain a streamlined and watertight structure.

Reviews (0)

Be the first to review “6 pcs Countersink Drill Set” Cancel reply

Related products

12 pcs Router Bit Set

A 12-piece router bit set typically refers to a collection of 12 individual router bits, each designed for specific woodworking tasks. Router bits are cutting tools used with a router, a power tool that hollows out an area in a piece of wood or other materials. The set usually includes a variety of bit types and shapes, such as straight bits, flush trim bits, chamfer bits, round-over bits, and others. These bits allow woodworkers to create different profiles, edges, and joinery styles in their projects. A comprehensive 12-piece router bit set provides versatility and convenience for a range of routing applications in woodworking.

5 pcs Forstner Bit Set

A 5-piece Forstner bit set refers to a collection of five Forstner drill bits designed for woodworking applications. Forstner bits are specialized cutting tools used to bore flat-bottomed holes with clean and precise edges in wood. The set usually includes five bits with varying diameters, allowing users to choose the appropriate size for different projects. These bits often feature a center point for accurate positioning, two sharp outer cutting edges, and a cylindrical shape. The set is versatile and suitable for tasks like drilling holes for dowels, creating pocket holes, or countersinking screws in woodworking projects.

5 pcs Glass Drill Set Hexagonal Handle

A 5-piece glass drill set with hexagonal handles typically refers to a collection of five drill bits specifically designed for drilling holes in glass surfaces. The term "hexagonal handle" indicates that the shank of each drill bit has a hexagonal (six-sided) shape, which can provide a better grip and prevent slipping when used with a compatible drill. These drill bits are specifically crafted for working with glass materials, offering precision and minimizing the risk of cracking or damaging the glass during the drilling process. The set may include different-sized bits to accommodate various hole diameters.

5 pcs Jig Saw Blade Set Teeth Mill

A 5 pcs Jig Saw Blade Set with teeth milled refers to a collection of five jig saw blades designed for use with a jig saw or saber saw. The term "teeth milled" indicates that the cutting edges of the blades have been precisely machined or milled to provide sharp and consistent teeth for efficient and accurate cutting. Jig saw blades are commonly used for making intricate and curved cuts in various materials such as wood, metal, plastic, and other similar substances. The set typically includes blades with different tooth configurations to suit various cutting applications and materials.

5 Piece Jig Saw Blade Set

The 5 Piece Jig Saw Blade Set is a versatile collection of blades designed for cutting various materials with a jigsaw. It typically includes different blade types with varying tooth counts for smooth or aggressive cuts. Ideal for DIYers and professionals, this set ensures compatibility with most standard jigsaws and provides options for precise, clean cuts in wood, plastic, or metal.

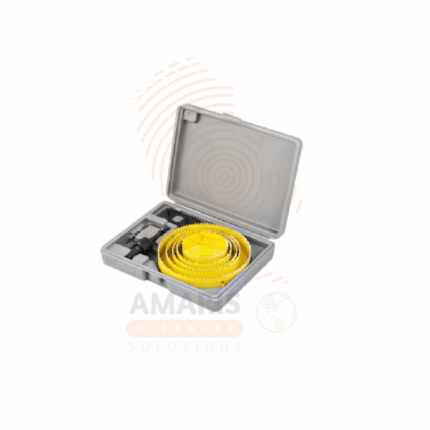

8 pcs Hole Saw Set

An 8-piece hole saw set typically refers to a collection of eight different hole saws, which are specialized cutting tools used in woodworking, metalworking, and other construction-related activities. Each set usually includes hole saws of various sizes, allowing users to create holes of different diameters in materials like wood, plastic, metal, or other surfaces.

A hole saw consists of a circular cutting blade with teeth on its edge and a central arbor that attaches to a drill. The set may include a range of sizes to accommodate various project requirements. The term "8-piece" indicates the total number of hole saws in the set.

These sets are commonly used for tasks such as installing doorknobs, creating holes for plumbing or electrical work, and other applications where a precise, circular opening is required in a material. The versatility of the set makes it a valuable tool for professionals and DIY enthusiasts alike

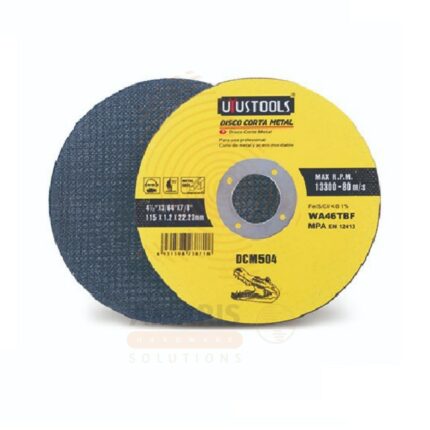

Cutting Wheel Thin

A cutting wheel, specifically a thin cutting wheel, is a specialized abrasive tool designed for precision cutting in various materials such as metal, plastic, or stone. It typically consists of a thin, flat, circular disc made of abrasive material bonded with resin or other substances. The thin profile of the cutting wheel allows for narrow cuts and reduces material wastage. These wheels are commonly used with angle grinders or rotary tools and are employed in applications ranging from metal fabrication and construction to DIY projects.

Cymbal Type Flap Disc

A "Cymbal Type Flap Disc" refers to a specific design of flap disc used in metalworking and grinding applications. The term "cymbal" in this context likely to the shape or configuration of the flap disc, resembling the round, concave form of a cymbal used in percussion instruments.

A Cymbal Type Flap Disc features abrasive flaps arranged in a circular pattern around a central hub, similar to how the surfaces of a cymbal are arranged in a circular fashion. These abrasive flaps are made of coated abrasive material and are used for grinding, blending, and finishing metal surfaces.

The design of the Cymbal Type Flap Disc allows for efficient material removal and provides a smooth finish on various metal surfaces. The arrangement of the flaps ensures that the abrasive material wears evenly during use, prolonging the life of the disc and maintaining consistent performance.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins

Reviews

There are no reviews yet.