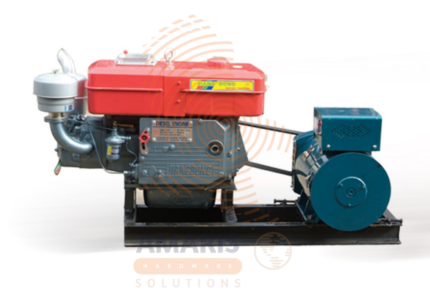

Diesel Genset(silent)

$1,203.85 Original price was: $1,203.85.$1,143.66Current price is: $1,143.66.

A Diesel Genset(silent) is a compact, enclosed power unit that combines a diesel engine and an alternator to produce electricity with significantly reduced noise levels. Designed with soundproof acoustic enclosures, vibration isolators, and mufflers, silent gensets are ideal for residential, commercial, and institutional applications where low noise pollution is critical. These units are used for standby, prime, or continuous power needs, offering fuel efficiency, reliability, and durability even in demanding environments. They are available in a range of power outputs and are engineered to meet stringent environmental and sound emission regulations.

Table of Contents

ToggleDiesel Genset(silent)

Uses

-

Emergency Power Supply

-

Provides backup electricity during power outages in homes, hospitals, offices, and critical infrastructure.

-

Maintains operation of essential equipment like lights, refrigerators, HVAC systems, and medical devices.

-

-

Industrial and Manufacturing Facilities

-

Supports uninterrupted operations in factories and production lines during grid failures.

-

Powers heavy machinery and control systems efficiently with minimal noise interference.

-

-

Data Centers and IT Infrastructure

-

Delivers silent, reliable power for servers and communication networks.

-

Prevents data loss and service disruption during blackouts.

-

-

Commercial Buildings and Shopping Malls

-

Ensures continuity of business operations such as lighting, elevators, security systems, and POS systems.

-

Operates discreetly to maintain a pleasant environment for customers and staff.

-

-

Medical and Healthcare Facilities

-

Maintains power to life-support machines, diagnostic tools, and refrigeration for medicine storage.

-

Quiet operation avoids disturbing patients and complies with healthcare noise standards.

-

-

Educational Institutions

-

Keeps schools, colleges, and training centers operational during power cuts.

-

Supports lab equipment, lighting, and computer systems without disrupting learning.

-

-

Events and Hospitality

-

Powers outdoor and indoor events, concerts, and weddings without disturbing the ambiance.

-

Provides electricity for sound systems, lighting, and catering equipment.

-

-

Construction Sites in Urban Zones

-

Supplies electricity to construction equipment while adhering to urban noise regulations.

-

Suitable for nighttime or high-traffic zone projects.

-

-

Telecom and Broadcasting

-

Supports transmission towers and broadcasting stations, ensuring 24/7 connectivity.

-

Essential in remote or noise-sensitive locations.

-

-

Military and Government Installations

-

Delivers consistent and quiet power for sensitive operations and remote command units.

-

Used in mobile units and temporary bases for silent energy support.

Safety Precautions

-

Wear Protective Gear

-

Use ear protection when servicing or operating near the genset for extended periods.

-

Wear steel-toed boots and gloves for mechanical protection.

-

Use goggles or face shields during maintenance to prevent eye injury.

-

-

Proper Installation

-

Install in a well-ventilated, dry area on a stable surface.

-

Ensure the acoustic enclosure vents and exhaust outlets are unobstructed.

-

Avoid enclosing the genset further, which can cause overheating or back pressure.

-

-

Electrical Safety

-

Use a transfer switch to avoid backfeeding power into the grid.

-

Keep connections dry and well-insulated.

-

Ensure grounding is done as per local electrical codes.

-

-

Fuel Safety

-

Store diesel in approved, labeled containers, away from heat sources or open flames.

-

Refuel only when the generator is switched off and cooled down.

-

Avoid fuel spills and clean immediately if they occur.

-

-

Fire Prevention

-

Keep a class ABC fire extinguisher nearby.

-

Regularly check for leaks in fuel lines or oil systems.

-

Clean debris or flammable materials from the surrounding area.

-

-

Noise and Emission Compliance

-

Ensure the acoustic enclosure is in good condition and all panels are securely closed.

-

Comply with local noise and emission regulations.

-

Inspect and replace damaged mufflers or silencers promptly.

-

-

Regular Maintenance

-

Check oil, coolant, and fuel levels regularly.

-

Clean filters and inspect belts and hoses for wear.

-

Test battery charge and terminal condition.

-

-

Avoid Overloading

-

Do not exceed the genset’s rated output.

-

Use load management systems or ATS to balance loads efficiently.

-

Overloading can cause overheating and long-term damage.

-

-

Emergency Preparedness

-

Know the emergency shutdown procedures.

-

Train all operators on basic troubleshooting and fire safety.

-

Post emergency contact numbers and procedures nearby.

-

-

Read the Manufacturer's Manual

-

Follow all guidelines for installation, operation, and maintenance.

-

Use only genuine parts and service as recommended by the manufacturer.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs