Folding Torx Wrench Set - Plastic Shell

$23.08 Original price was: $23.08.$21.93Current price is: $21.93.

Boom Sprayer

$780.77 Original price was: $780.77.$741.73Current price is: $741.73.

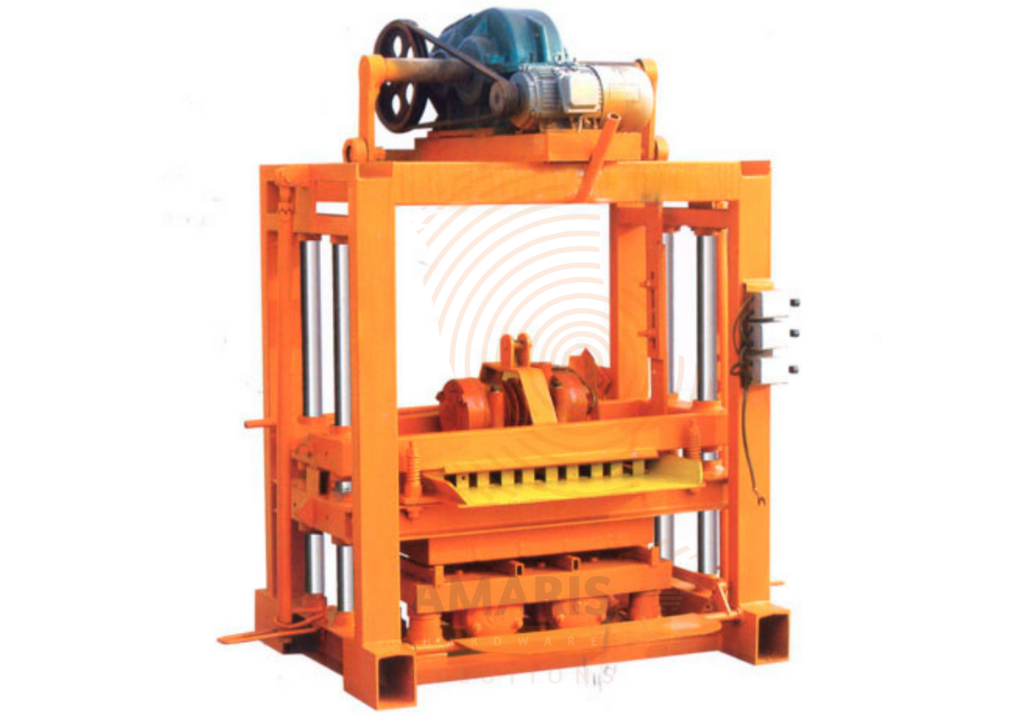

Block Making Machine

$626.92 Original price was: $626.92.$595.57Current price is: $595.57.

WhatsApp Order

A Block Making Machine is a specialized construction equipment designed to produce high-quality concrete blocks, bricks, and pavers used in building and infrastructure projects. It automates the process of mixing, molding, compacting, and curing concrete materials into consistent, uniform blocks of various sizes and shapes. These machines can be manual, semi-automatic, or fully automatic, depending on their level of automation and production capacity. They are widely used in commercial, industrial, and residential construction projects for producing large volumes of concrete masonry units efficiently.

Description

Table of Contents

ToggleBlock Making Machine

Uses

-

Manufacturing concrete blocks for walls, pavements, and fences

-

Producing hollow blocks, solid blocks, paving stones, and curbstones

-

Creating interlocking blocks for retaining walls and roadways

-

Mass production of blocks for commercial and residential construction

-

On-site block production to reduce material transportation costs

-

Fabricating colored or decorative concrete blocks for aesthetic finishes

-

Supporting low-cost housing projects through localized production

-

Making heat-resistant and soundproof blocks for specialized structures

-

Creating foundation blocks for civil engineering applications

-

Producing blocks for boundary walls, partitions, and utility buildings

-

Used in municipal projects for sidewalks and urban development

-

Creating ventilated blocks for enhanced airflow in buildings

-

Suitable for rural or remote construction sites with limited access to supply chains

-

Used in eco-friendly building solutions by incorporating recycled materials

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Wear Personal Protective Equipment (PPE)

-

Use safety goggles to protect eyes from dust and debris

-

Wear gloves to prevent hand injuries during material handling

-

Use ear protection if working with high-noise machines

-

Wear safety boots and durable clothing on-site

-

-

Read and Follow the User Manual

-

Familiarize yourself with machine controls, emergency stops, and operational guidelines

-

Follow manufacturer recommendations for setup, maintenance, and troubleshooting

-

-

Check Equipment Before Use

-

Inspect hydraulic systems, electrical components, and molds for wear or damage

-

Ensure all safety guards and sensors are functional

-

-

Use Proper Lifting Techniques

-

Handle raw materials and finished blocks using correct posture or mechanical aids

-

-

Keep Work Area Clean

-

Remove debris and concrete spills to prevent slips and trips

-

Maintain clear access around the machine for safe operation

-

-

Avoid Manual Contact with Moving Parts

-

Never reach into the machine while it is running

-

Use tools or sticks to dislodge material jams

-

-

Operate with Trained Personnel Only

-

Ensure operators are trained in machine operation and emergency procedures

-

-

Perform Routine Maintenance

-

Regularly lubricate mechanical parts and clean molds

-

Replace worn parts to prevent accidents or malfunctions

-

-

Avoid Overloading the Machine

-

Do not exceed the capacity specified by the manufacturer to prevent breakdowns or injury

-

-

Use in a Well-Ventilated Area

-

Ensure adequate airflow if using chemicals or additives with the concrete mix

Related products

Boom Sprayer

A Boom Sprayer is an agricultural implement designed to apply liquids such as herbicides, pesticides, fertilizers, and water evenly over large crop areas. It features a horizontal boom equipped with multiple nozzles spaced at intervals, allowing for wide coverage and uniform spray distribution. Boom sprayers can be mounted on tractors, pulled behind as trailers, or be self-propelled units. They enhance the efficiency and accuracy of spraying operations in farming, reducing manual labor and ensuring effective crop protection and nutrition.

Box Beam Spirit Level Pro – Magnetic

A Box Beam Spirit Level Pro - Magnetic is a precision hand tool used for measuring the levelness and plumbness of surfaces. Its rigid box-shaped aluminum body provides durability and stability during use. The tool contains liquid-filled vials with air bubbles to indicate horizontal, vertical, and 45-degree angles. The magnetic base allows for secure attachment to metal surfaces, enabling hands-free operation. This level is essential in construction, carpentry, metalworking, and any tasks requiring accurate surface alignment.

Flat Webbing Slings

A flat webbing sling is a flexible and durable lifting or towing device made from a flat strip of synthetic material, typically polyester, nylon, or polypropylene. These slings are designed for various material handling applications, such as lifting and securing loads in construction, manufacturing, and transportation industries. The flat design allows for a wide surface area, distributing the load evenly and reducing the risk of damage to the load. Flat webbing slings often feature reinforced loops at each end for attachment to lifting equipment, providing a versatile and reliable solution for lifting and moving heavy objects.

Gasoline Concrete Vibrator

A gasoline concrete vibrator is a construction tool powered by a gasoline engine and designed for consolidating and compacting freshly poured concrete. It typically consists of a vibrating head or poker attached to a flexible shaft, which is connected to the engine. The vibrator is inserted into the wet concrete to eliminate air bubbles, improve the overall strength and density of the concrete, and ensure a smooth and uniform finish. The gasoline engine provides the necessary power for the vibration, making the tool versatile and suitable for use in locations where electric power may not be readily available.

Putty Trowel-Stainless Steel

A Putty Trowel-Stainless Steel, specifically one made of stainless steel, is a handheld tool designed for applying and smoothing putty or plaster onto surfaces such as walls, ceilings, or other construction materials. The tool typically consists of a flat, narrow, and flexible stainless steel blade that allows for precise application and smoothing of putty or other similar materials. The stainless steel construction provides durability, resistance to corrosion, and easy cleaning, making it a preferred choice for professionals in the construction and finishing trades.

Ratchet Tie Down Straps Set

A Ratchet Tie Down Straps Set typically refers to a pair of specialized straps used for securing and fastening cargo or items during transportation. These sets commonly include two individual straps, each equipped with a ratcheting mechanism for easy tightening and securing of the load. The straps usually consist of durable webbing material and feature hooks or other fastening mechanisms on each end. The primary purpose of these tie-down straps is to provide a reliable and adjustable means of securing items to prevent movement, shifting, or potential damage during transit. They are widely used in various applications, including securing loads on vehicles, trailers, or in storage.

Tile Cutter

A tile cutter is a manual or powered tool specifically designed for cutting ceramic, porcelain, or other types of tiles. It typically consists of a sharp cutting wheel or blade that is guided along a straight edge to score the tile's surface. After scoring, the tile is then snapped or separated along the scored line, resulting in a clean and precise cut. Tile cutters are widely used in construction, home improvement, and tiling projects to achieve accurate and customized tile sizes for various installations.

Winch

A winch is a mechanical device used to pull in, let out, or adjust the tension of a rope, cable, or chain. It consists of a spool (or drum) operated manually or powered by electricity, hydraulics, or a combustion engine. Winches are commonly used in construction, vehicle recovery, marine applications, off-road towing, and industrial lifting. Their ability to exert controlled pulling force makes them essential in material handling and rigging operations where moving heavy objects with precision is required.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs