Angle Grinder Stand

The Angle Grinder Stand converts your handheld angle grinder into a stable cutting station for precise, repeatable cuts. Ideal for metal, tile, and stonework, it enhances control and safety while reducing fatigue and cutting errors. Perfect for DIYers and professionals, it’s a compact, affordable solution for improving grinder performance in any workspace.

Angle Grinder Stand Uses

1. Precision Cutting of Metal and Steel Rods

The Angle Grinder Stand transforms a standard handheld angle grinder into a stationary cutting tool, allowing users to make precise, controlled cuts on metal pipes, rods, rebar, and steel bars. It ensures square cuts and repeatability—especially useful in fabrication, construction, and welding applications.

2. Improved Safety During Cutting Operations

Using an angle grinder freehand for cutting can be hazardous. A grinder stand stabilizes the tool, reducing the risk of kickback, accidental slips, or misalignment. It provides added protection, especially when working with tough materials like iron, steel, or aluminum.

3. Straight and Angled Cuts on Tile and Stone

When used with a diamond cutting disc, the angle grinder stand enables straight or angled cuts on ceramic tile, granite, marble, or concrete pavers. This makes it an excellent accessory for tiling, flooring, and stonework where clean, accurate edges are important.

4. Efficient Cutting for Home Projects and Repairs

Whether you’re building a metal gate, modifying brackets, or cutting bolts for furniture assembly, this stand allows faster, more controlled work. It’s a valuable addition to any DIY setup, turning your grinder into a mini chop saw for household tasks.

5. Repetitive Cuts with Consistent Results

When cutting multiple pieces to the same length or angle, the angle grinder stand provides the consistency needed for uniformity. It’s ideal for jobs like cutting framing members, fence rails, or fabrication components.

6. Smoother Cutting with Less Effort

The guided motion of the stand allows for even downward pressure during the cut, improving finish quality and reducing user fatigue. This makes it easier to cut denser materials without relying entirely on arm strength or hand-eye coordination.

7. Compact Alternative to a Chop Saw

For users with limited space or budget, the angle grinder stand offers a space-saving solution that delivers many of the same benefits as a metal chop saw. It’s especially useful in small workshops, garages, or mobile workstations.

8. Enhanced Versatility with Multiple Grinder Models

Most grinder stands are adjustable and compatible with various angle grinder sizes, allowing you to use different disc types and diameters depending on the project. This makes it a flexible, cost-effective upgrade to your power tool kit.

Safety Precautions

- Secure Stand to Workbench – Use clamps or bolts to prevent movement during operation.

- Check Grinder Compatibility – Ensure the grinder fits snugly in the mounting bracket.

- Wear Full PPE – Safety goggles, gloves, and hearing protection.

- Verify Disc Guard Alignment – Adjust to protect against sparks and debris.

- Disconnect Power – Unplug grinder before mounting/dismounting.

Storage Procedures

- Clean After Use – Remove metal dust and debris.

- Lubricate Adjustable Parts – Apply light oil to hinges and locking mechanisms.

- Store in Dry Place – Prevent rust on metal components.

- Keep Grinder Separate – Do not store mounted on the stand.

Critical Warnings

- NEVER operate without securing the stand first.

- NEVER exceed the stand’s weight capacity.

- NEVER force adjustments while the grinder is running.

Angle Grinder

Stand for 115 MM / 125MM

Aluminum material

Packed by color box

115 / 125/ 150 MM

Available with different specifications:

Include:

Angle Grinder

Stand for 180 MM / 230MM

Aluminum material

Packed by color box

180 7”/230 MM 9”

Related products

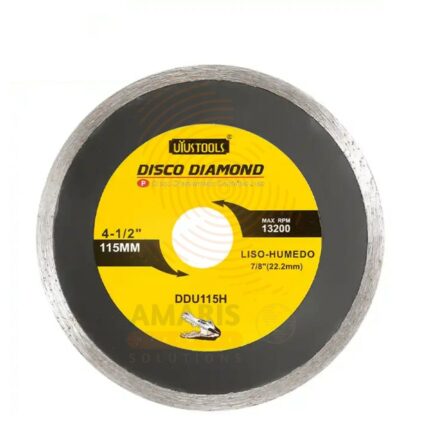

Arbor

Diamond Cutting Blade(Wet) – Cold Press 12 pieces

Drill, Chuck & Key

Flat Knotted Wire Wheel

Forstner Drill Bits

SDS Plus Stone Flat Chisel

SDS Plus Stone Pointed Chisel

Twist Wire Bevel Brush – Metric

- Twist Wire: This likely refers to the type of bristle or filament used in the brush. "Twist wire" suggests that the bristles are made by twisting wires together, which can provide durability and stiffness.

- Bevel Brush: A bevel brush typically has bristles that are set at an angle to the brush surface. This design allows for more effective cleaning or brushing in certain applications, especially where precision or reaching corners is important.

- Metric for Hardware Use: The term "metric" implies that the brush is designed or measured using the metric system, which is common in many countries around the world. "For hardware use" indicates that the brush is intended for applications in the hardware industry.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management – Ties & Fasteners

Cable Management – Ties & Fasteners Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.