Belt Sander

$ 107.69 Original price was: $ 107.69.$ 102.31Current price is: $ 102.31.

Bench Plane

$ 34.23 Original price was: $ 34.23.$ 32.52Current price is: $ 32.52.

Bench Grinder

$ 50.00 Original price was: $ 50.00.$ 47.50Current price is: $ 47.50.

WhatsApp Order

A bench grinder is a power tool that typically consists of two rotating abrasive wheels mounted on a spindle. The wheels can perform various tasks, such as sharpening, shaping, grinding, and polishing metal or other materials. The 350W in “Bench Grinder 350W” refers to the power of the grinder, with 350 watts being the electrical power consumption or output of the motor. This type of bench grinder is suitable for light to moderate-duty tasks, making it a versatile tool for home workshops, DIY projects, and small-scale metalworking applications.

Description

Table of Contents

ToggleBench Grinder

Uses

-

Sharpening Tools:

-

Bench grinders are commonly used for sharpening a variety of cutting tools, including chisels, knives, scissors, and drill bits.

-

-

Grinding Metal:

-

It is effective for grinding and shaping metal surfaces, removing burrs, and smoothing welds. This makes it useful for tasks such as preparing metal pieces for fabrication or repair.

-

-

Debarring:

-

Bench grinders are excellent for removing burrs or sharp edges from metal parts, providing a smoother and safer finish.

-

-

Polishing:

-

With the right attachments or wheels, a bench grinder can be used for polishing metal surfaces, restoring shine, and removing oxidation.

-

-

Rust Removal:

-

The abrasive wheels on a bench grinder are effective at removing rust and corrosion from metal surfaces, helping to restore them to a clean and usable condition.

-

-

Tool Rest Modification:

-

Users often modify the tool rest on a bench grinder to create custom angles for sharpening and grinding specific tools.

-

-

Honing Blades:

-

In addition to sharpening, a bench grinder can be used for honing the edges of blades to improve their cutting performance.

-

-

Light Material Removal:

-

It’s suitable for light material removal tasks, such as shaping small metal pieces or preparing surfaces for welding.

-

-

DIY and Home Improvement:

-

Bench grinders are commonly used in home workshops for a variety of do-it-yourself (DIY) and home improvement projects.

-

-

Grinding Non-Metallic Materials:

-

Depending on the type of wheels used, bench grinders can also be employed for grinding and shaping non-metallic materials like plastic or wood.

-

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Personal Protective Equipment (PPE):

-

Wear safety glasses or goggles to protect your eyes from dust and flying debris.

-

Wear work gloves to protect your hands from rough surfaces and heat.

-

Wear ear protection to prevent hearing damage from prolonged exposure to noise.

-

Wear a dust mask or respirator to avoid inhaling fine dust particles.

-

Read and Understand the User Manual:

-

Familiarize yourself with the user manual before operating the belt sander. Follow all manufacturer instructions.

-

Inspect Tools Before Use:

-

Check the sander for any damage or wear.

-

Ensure belts are properly installed and in good condition.

-

Secure Work Area:

-

Keep the work area clean and well-lit.

-

Ensure the workpiece is clamped or secured to prevent movement.

-

Proper Operation:

-

Operate the sander with both hands and maintain a firm grip.

-

Avoid forcing the sander; let the tool do the work.

-

Position Yourself Safely:

-

Stand in a balanced position.

-

Keep fingers, hair, and loose clothing away from moving parts.

-

Use Dust Collection:

-

If available, connect a dust extraction system or vacuum to reduce airborne dust.

-

Store Tools Properly:

-

Store the belt sander in a dry, secure place when not in use.

-

Training and Experience:

-

Ensure operators are trained and familiar with the safe use of belt sanders.

Related products

Bi-Metal Hole Saw Set

A Bi-Metal Hole Saw Set refers to a collection of nine hole saws, each constructed with a bi-metal design. A hole saw is a cylindrical cutting tool used to create holes in various materials such as wood, metal, plastic, and more. The term "bi-metal" indicates that the hole saws are made from two different types of metals, typically high-speed steel (HSS) and a more durable alloy like cobalt. This combination enhances the hole saw's cutting performance, making it suitable for a wide range of applications and providing increased durability and longevity. The set typically includes hole saws of different sizes to accommodate various hole diameters, making it a versatile tool for professionals and DIY enthusiasts alike.

Big Battery Pro

A " Big Battery Pro" typically refers to a rechargeable lithium-ion battery with a nominal voltage of 20 volts. The nominal voltage represents the average voltage output over the majority of the battery's discharge cycle. It's important to note that the actual voltage during use may fluctuate within a specified range.

These batteries are commonly used to power various devices, including power tools, garden equipment, and other portable electronic devices. The "20V" designation is a standardized measure indicating the electrical potential of the battery, providing a general indication of its power output.

Keep in mind that when considering a 20V battery, it's essential to verify compatibility with the specific device or tool it is intended for. Additionally, different manufacturers may have variations in the actual voltage, capacity, and features of their 20V battery products. Checking the product documentation or contacting the manufacturer for detailed specifications is recommended for accurate information.

Cement And Paint Mixer

A cement and paint mixer is a mechanical device designed to efficiently and homogeneously blend cement or paint constituents to achieve a uniform and consistent mixture. Typically utilized in construction and painting applications, these mixers come in various designs, including portable or stationary models. They feature rotating blades, paddles, or agitators that facilitate the thorough mixing of dry or liquid materials, ensuring the creation of a well-mixed and homogeneous product suitable for construction or painting purposes.

Cement Blender

A cement blender is a mechanical device designed for the purpose of mixing and blending various components of cementitious materials, such as cement, sand, and water, to create a homogenous mixture. This blended mixture is commonly used in construction and building projects, particularly for applications like concrete production. The blender typically features a rotating drum or container that facilitates the thorough mixing of the ingredients, ensuring a consistent and uniform composition for the construction materials.

Chuck Die Grinder

A Chuck Die Grinder is a handheld power tool equipped with a collet or chuck that holds a rotary burr or abrasive head. This tool is commonly used for precision grinding, polishing, and shaping of metal, wood, plastic, and other materials. Chuck Die Grinders are versatile and compact, allowing for intricate and detailed work in various applications, including metalworking, woodworking, and fabrication. They are widely employed in industries such as machining, automotive, and aerospace, as well as by hobbyists and craftsmen for tasks requiring fine control and high-speed material removal.

Cordless Angle Grinder

A cordless angle grinder is a handheld power tool designed for cutting, grinding, and polishing materials, typically metal or masonry. Unlike traditional angle grinders that are powered by electrical cords, cordless angle grinders are equipped with rechargeable batteries, providing greater mobility and flexibility in various work environments. These tools often feature a rotating disc or wheel that can be fitted with different abrasive attachments, allowing users to perform a variety of tasks such as cutting metal, smoothing welds, or removing rust and paint. Cordless angle grinders are widely used in construction, metalworking, and fabrication applications.

Glass Drill Set Straight Handle

A Glass Drill Set Straight Handle refers to a set of five drill bits specifically designed for drilling into glass surfaces. Each drill bit in the set typically has a straight handle, making it easier to grip and control during the drilling process. These drill bits are crafted with materials and designs that enhance their ability to cut through glass without causing cracks or shattering. The set may include a variety of drill bit sizes to accommodate different drilling needs and applications on glass surfaces.

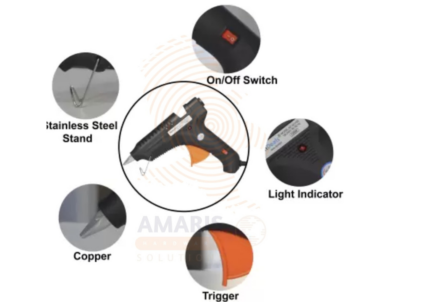

Glue Gun

A glue gun, specifically a 40-watt glue gun, is a handheld tool designed for dispensing hot melt adhesive in a controlled and precise manner. It typically consists of a heating element powered by a 40-watt electrical system, a trigger mechanism to control the adhesive flow, and a nozzle for directing the melted glue. The glue stick, usually made of thermoplastic materials, is inserted into the gun, melted by the heating element, and then extruded through the nozzle as a liquid adhesive. This versatile tool is commonly used in various DIY projects, crafts, and home repairs due to its quick and efficient bonding capabilities. The 40-watt power rating indicates the electrical power consumed by the glue gun to heat the adhesive to its melting point.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs