Forstner Bits

$ 18.85 Original price was: $ 18.85.$ 17.91Current price is: $ 17.91.

Fretsaw Frame

$ 15.73 Original price was: $ 15.73.$ 14.94Current price is: $ 14.94.

Forstner Drill Bits

$ 14.62 Original price was: $ 14.62.$ 13.89Current price is: $ 13.89.

WhatsApp Order

A Forstner drill bit is a specialized cutting tool used in woodworking to create flat-bottomed holes with smooth sides. Unlike traditional twist or spade drill bits, Forstner bits are characterized by a cylindrical shape with a flat bottom and a rim that cuts the perimeter of the hole. These bits are well-suited for precision drilling tasks, such as creating boreholes for dowels or hinge cups, as they produce clean and accurate results, minimizing tear-out and splintering in the wood. Forstner drill bits are commonly used in cabinetry, furniture making, and other woodworking applications where precise and clean hole drilling is essential.

Description

Table of Contents

ToggleForstner Drill Bits

Uses

-

Hinge Installation: Forstner bits are often used to drill precise, flat-bottomed holes for installing hinges in doors, cabinets, and furniture. The clean-cut edges and flat bottoms ensure a proper fit for the hinge.

-

Cabinetmaking: Woodworkers use Forstner bits to create holes for shelf pins, allowing adjustable shelving within cabinets. The flat-bottomed holes provide stable support for the shelves.

-

Dowel Hole Drilling: Forstner bits are ideal for drilling holes to insert dowels. This is common in joinery and woodworking projects where dowels are used for alignment or structural reinforcement.

-

Concealed Fasteners: These bits are suitable for creating holes for concealed fasteners or screws used in woodworking projects where a seamless or hidden appearance is desired.

-

Woodturning: Wood turners use Forstner bits to create clean and accurate recesses for inlays, as well as for drilling holes in turned wood pieces.

-

Wooden Boxes and Containers: For creating finger or handhold holes in wooden boxes or containers, Forstner bits are often preferred because of their ability to produce smooth and precise holes.

-

Making Speaker Ports: Woodworkers and DIY enthusiasts use Forstner bits to create speaker ports in speaker cabinets. The precision of these bits ensures a proper fit for the speaker components.

-

Wooden Toys: In the crafting of wooden toys, Forstner bits are used to create wheels, axles, and other components requiring precise, flat-bottomed holes.

-

Tool Handles: Forstner bits are employed in creating holes for handles in tools like mallets, hammers, or other hand tools where a comfortable grip is essential.

-

Bowl and Plate Turning: Wood turners use Forstner bits to create the recesses needed for attaching faceplates or chucks to securely hold bowl or plate blanks on a lathe.

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Wear Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, including safety glasses or goggles to protect your eyes from wood chips and debris. Additionally, hearing protection may be necessary, especially when working with larger and more powerful drills.

-

Secure Work piece Properly : Secure the work piece firmly using clamps or other suitable methods. This ensures that the material remains stable during drilling, preventing it from moving or rotating unexpectedly.

-

Select the Right Speed: Use the correct drill speed for the specific material you are working with. Refer to the drill press or drill's manual for guidance on speed settings. Using the wrong speed can lead to overheating and reduced effectiveness.

-

Use a Drill Press or Stable Base: Whenever possible, use a drill press for increased stability and control. If using a hand-held drill, make sure you have a stable base, and maintain a firm grip on the tool.

-

Check Bit Sharpness: Ensure that the Forstner bit is sharp before use. Dull bits can cause overheating, splintering, and may lead to less precise holes. Sharpen or replace the bit as needed.

-

Depth Stop Setting: Set the depth stop on the drill press or the drill itself to prevent over-drilling. This helps in achieving consistent and accurate hole depths.

-

Clear the Workspace: Remove any unnecessary tools, debris, or obstructions from the work area to prevent accidents. Keep the workspace organized and free of tripping hazards.

-

Avoid Loose Clothing and Jewelry: Wear appropriate clothing, avoiding loose-fitting garments that could get caught in the drill. Remove jewelry that might pose a risk of entanglement.

-

Inspect the Drill Bit: Before each use, inspect the Forstner bit for any signs of damage, wear, or defects. Replace any damaged or worn bits promptly to ensure safe and effective operation.

-

Follow Manufacturer's Guidelines: Always follow the manufacturer's guidelines and recommendations for the Forstner bit, drill press, or drill you are using. This includes maintenance, operating procedures, and any safety precautions provided in the manual.

-

Stay Alert and Focused: Maintain full attention while operating the drill. Avoid distractions and stay focused on the task at hand to reduce the risk of accidents.

Related products

Big Battery Pro

A " Big Battery Pro" typically refers to a rechargeable lithium-ion battery with a nominal voltage of 20 volts. The nominal voltage represents the average voltage output over the majority of the battery's discharge cycle. It's important to note that the actual voltage during use may fluctuate within a specified range.

These batteries are commonly used to power various devices, including power tools, garden equipment, and other portable electronic devices. The "20V" designation is a standardized measure indicating the electrical potential of the battery, providing a general indication of its power output.

Keep in mind that when considering a 20V battery, it's essential to verify compatibility with the specific device or tool it is intended for. Additionally, different manufacturers may have variations in the actual voltage, capacity, and features of their 20V battery products. Checking the product documentation or contacting the manufacturer for detailed specifications is recommended for accurate information.

Cement Blender – SDS Plus

A Cement Blender - SDS Plus mechanism typically refers to a power tool designed for mixing cement, mortar, or other construction materials. The term "SDS-PLUS" refers to a specific chuck and bit system commonly used in rotary hammers and drills. SDS-PLUS chucks allow for quick and secure attachment of drill bits and other accessories.

In the context of a cement blender with SDS-PLUS, it likely means that the tool has a specialized chuck system for easy attachment of mixing paddles or blades used in blending cement or similar materials. The SDS-PLUS system is known for its quick-change capability, enhancing efficiency and convenience when working with different attachments. The blender's design may include features to ensure effective mixing of construction materials, making it suitable for tasks like preparing mortar or concrete on construction sites.

Double – End Bits Set

A Double - End Bits Set typically refers to a collection of interchangeable tool bits designed for use with screwdrivers, power drills, or similar tools. Each bit in the set has two distinct ends with different types or sizes of tips, allowing the user to perform various tasks without needing multiple individual bits. These sets often include a variety of common bit types, such as Phillips, slotted, Torx, or hex, providing versatility for different screw and fastener types. The double-ended design allows users to flip the bit and switch between different tips easily, making it a convenient and space-saving solution for various applications.

Fast Charger

A fast charger is a device designed to quickly recharge compatible batteries with a voltage rating of 20 volts. The "fast" designation implies that the charger is engineered to deliver a higher charging current, allowing for a more rapid replenishment of the battery's energy capacity compared to standard chargers. This type of charger is commonly used for power tools, electronic devices, or other equipment that operates on 20V batteries, providing users with a more efficient and time-saving charging solution.

Forstner Bit Set

A Forstner bit set typically refers to a collection of five Forstner drill bits designed for woodworking applications. Forstner bits are specialized cutting tools used to bore flat-bottomed holes with clean and precise edges in wood. The set usually includes five bits with varying diameters, allowing users to choose the appropriate size for different projects. These bits often feature a center point for accurate positioning, two sharp outer cutting edges, and a cylindrical shape. The set is versatile and suitable for tasks like drilling holes for dowels, creating pocket holes, or countersinking screws in woodworking projects.

Forstner Bits

A Forstner bit is a specialized woodworking drill bit designed for creating flat-bottomed holes with a clean and precise finish. Unlike traditional twist drill bits, Forstner bits have a cylindrical, flat-bottomed shape with a center point and cutting edges along the circumference. These bits are commonly used when a smooth and accurately sized hole without breakthrough is required in woodworking applications, such as for drilling holes for dowels or creating recesses for hardware like hinges. Forstner bits are known for their ability to produce clean and splinter-free boreholes, making them popular among woodworkers and cabinetmakers for tasks that demand precision and aesthetics.

Gasoline Auger Machine

A gasoline auger machine is a power tool designed for drilling holes in the ground using a rotating helical screw blade, commonly known as an auger. Unlike electric or manual augers, a gasoline auger machine is powered by a gasoline engine, providing greater mobility and independence from electrical power sources. This type of machine is commonly used in construction, landscaping, and agriculture for tasks such as digging holes for fence posts, planting trees, or installing various types of foundations. The gasoline engine provides the necessary power to turn the auger bit efficiently, making it suitable for heavy-duty and remote applications where access to electricity may be limited.

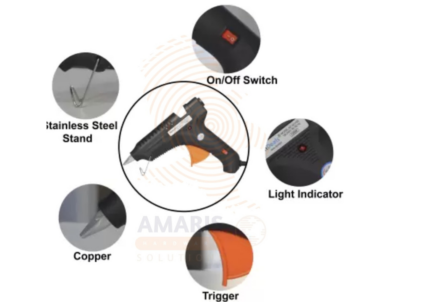

Glue Gun

A glue gun, specifically a 40-watt glue gun, is a handheld tool designed for dispensing hot melt adhesive in a controlled and precise manner. It typically consists of a heating element powered by a 40-watt electrical system, a trigger mechanism to control the adhesive flow, and a nozzle for directing the melted glue. The glue stick, usually made of thermoplastic materials, is inserted into the gun, melted by the heating element, and then extruded through the nozzle as a liquid adhesive. This versatile tool is commonly used in various DIY projects, crafts, and home repairs due to its quick and efficient bonding capabilities. The 40-watt power rating indicates the electrical power consumed by the glue gun to heat the adhesive to its melting point.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs