Double Sided Tape

$ 12.19 Original price was: $ 12.19.$ 11.58Current price is: $ 11.58.

Drill Brush Set

$ 17.54 Original price was: $ 17.54.$ 16.66Current price is: $ 16.66.

High pressure washer

$ 134.46 Original price was: $ 134.46.$ 127.74Current price is: $ 127.74.

WhatsApp Order

A High pressure washer, rated at 2000 watts, is a powerful cleaning device designed for various applications, such as cleaning surfaces, vehicles, outdoor spaces, and more. The “2000W” indicates the power consumption or wattage of the washer, suggesting a robust motor that can generate high water pressure for effective cleaning. This type of pressure washer is likely to deliver strong water jets, making it suitable for tackling tough dirt, grime, and stains in residential or industrial settings. The versatility and efficiency of a 2000W high-pressure washer make it a popular choice for tasks that demand substantial cleaning power.

Categories: Hoses & Tubing, Industrial Hoses, INDUSTRIAL SUPPLIES, PLUMBING SUPPLIES, Power Tool Accessories (Blades, Bits, Discs), POWER TOOLS

Tags: electric pressure washer, garden cleaning tool, heavy-duty washer, high-pressure washer, outdoor cleaning equipment, power washer, pressure cleaning tool, surface cleaner, water pressure washer

Description

Table of Contents

ToggleHigh pressure washer

Uses

-

Exterior Cleaning of Buildings:

-

Facade and exterior wall cleaning.

-

Removal of dirt, algae, and mildew.

-

-

Vehicle Washing:

-

Cleaning cars, trucks, motorcycles, and other vehicles.

-

Removing road grime, mud, and grease.

-

-

Patio and Deck Cleaning:

-

Removing dirt, stains, and moss from outdoor surfaces.

-

Preparing surfaces for painting or sealing.

-

-

Driveway and Walkway Cleaning:

-

Eliminating oil stains, tire marks, and other tough stains.

-

Restoring the appearance of concrete and paving.

-

-

Garden Furniture Cleaning:

-

Cleaning outdoor furniture, including tables and chairs.

-

Removing accumulated dirt and weather-related stains.

-

-

Fence and Gate Cleaning:

-

Removing dirt, mold, and mildew from wooden or metal fences.

-

Restoring the appearance of gates and fences.

-

-

Gutter Cleaning:

-

Clearing debris and leaves from gutters and downspouts.

-

Preventing clogs and ensuring proper water drainage.

-

-

Grill and Barbecue Cleaning:

-

Removing grease, char, and food residue from grills.

-

Keeping outdoor cooking equipment clean and well-maintained.

-

-

Boat and Marine Equipment Cleaning:

-

Washing boats, jet skis, and other marine equipment.

-

Removing salt deposits and marine debris.

-

-

Commercial and Industrial Cleaning:

-

Cleaning machinery and equipment in industrial settings.

-

Degreasing surfaces in workshops and factories.

-

-

Construction Site Cleanup:

-

Removing construction debris and dirt from equipment.

-

Cleaning tools and machinery on construction sites.

-

-

Pool and Pool Deck Cleaning:

-

Cleaning pool decks, tiles, and surrounding areas.

-

Removing algae and water stains from pool surfaces.

-

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Wear Personal Protective Equipment (PPE):

-

Always wear safety goggles or a face shield to protect your eyes from high-pressure spray and debris.

-

Use gloves and sturdy footwear to protect your hands and feet.

-

Inspect the Equipment:

-

Check hoses, nozzles, and fittings for damage or leaks before each use.

-

Replace any damaged parts immediately to prevent accidents.

-

Use the Correct Nozzle and Pressure Setting:

-

Select the appropriate nozzle for the task to avoid damaging surfaces or causing injury.

-

Adjust the pressure to a safe and suitable level for the material being cleaned.

-

Maintain a Safe Distance:

-

Keep the spray nozzle at a safe distance from the surface and from yourself to avoid injury or damage.

-

Never point the spray at people, animals, or electrical outlets.

-

Secure the Work Area:

-

Clear the area of obstacles, pets, and bystanders before starting.

-

Ensure proper footing and avoid slippery or unstable surfaces.

-

Avoid Electrical Hazards:

-

Do not use the pressure washer near electrical equipment or outlets unless it is rated for such use.

-

Keep electrical cords and plugs dry and away from water.

-

Follow Manufacturer’s Instructions:

-

Adhere strictly to the manufacturer’s guidelines for operation, maintenance, and safety.

-

Use only recommended accessories and replacement parts.

-

Turn Off and Depressurize:

-

Always turn off the machine and relieve pressure from the system before changing nozzles or performing maintenance.

-

Store Safely:

-

After use, properly drain and store the washer and accessories to prevent damage and accidents.

-

Training and Awareness:

-

Ensure operators are trained on the safe use of high-pressure washers and understand potential hazards.

Related products

Cement And Paint Mixer

A cement and paint mixer is a mechanical device designed to efficiently and homogeneously blend cement or paint constituents to achieve a uniform and consistent mixture. Typically utilized in construction and painting applications, these mixers come in various designs, including portable or stationary models. They feature rotating blades, paddles, or agitators that facilitate the thorough mixing of dry or liquid materials, ensuring the creation of a well-mixed and homogeneous product suitable for construction or painting purposes.

Cement Blender

A cement blender is a mechanical device designed for the purpose of mixing and blending various components of cementitious materials, such as cement, sand, and water, to create a homogenous mixture. This blended mixture is commonly used in construction and building projects, particularly for applications like concrete production. The blender typically features a rotating drum or container that facilitates the thorough mixing of the ingredients, ensuring a consistent and uniform composition for the construction materials.

Cement Blender – SDS Plus

A Cement Blender - SDS Plus mechanism typically refers to a power tool designed for mixing cement, mortar, or other construction materials. The term "SDS-PLUS" refers to a specific chuck and bit system commonly used in rotary hammers and drills. SDS-PLUS chucks allow for quick and secure attachment of drill bits and other accessories.

In the context of a cement blender with SDS-PLUS, it likely means that the tool has a specialized chuck system for easy attachment of mixing paddles or blades used in blending cement or similar materials. The SDS-PLUS system is known for its quick-change capability, enhancing efficiency and convenience when working with different attachments. The blender's design may include features to ensure effective mixing of construction materials, making it suitable for tasks like preparing mortar or concrete on construction sites.

Chain Saw Adapter for Angle Grinder

Chain Saw Adapter for Angle Grinder typically refer to components that allow you to attach or use certain accessories with your chainsaw or grinder.

- Chainsaw Adapter:

- A device that enables the use of a 12-inch chainsaw blade on a chainsaw designed for a different blade size. This adapter allows you to customize or replace the original chainsaw blade with a 12-inch one, potentially for different cutting applications.

- Grinder Adapter:

- An accessory that allows you to attach a grinder to a 12-inch chainsaw, converting it into a chainsaw chain sharpener. This adapter facilitates the grinding or sharpening of the chainsaw chain, ensuring optimal cutting performance.

Circular Saw Blade for Wood

A circular saw blade for wood is a cutting tool designed specifically for use with a circular saw. It typically consists of a flat, circular disc with sharp teeth along its outer edge. The blade is mounted onto the arbor of the circular saw, and as the saw operates, the blade spins rapidly to cut through wood materials. Circular saw blades for wood are specifically engineered to make efficient and clean cuts in wood, and they come in various sizes and tooth configurations to suit different cutting tasks and wood types. The teeth on the blade are strategically shaped and arranged to ensure smooth and precise cutting while minimizing splintering and tear-out on the wood surface.

Gasoline Auger Machine

A gasoline auger machine is a power tool designed for drilling holes in the ground using a rotating helical screw blade, commonly known as an auger. Unlike electric or manual augers, a gasoline auger machine is powered by a gasoline engine, providing greater mobility and independence from electrical power sources. This type of machine is commonly used in construction, landscaping, and agriculture for tasks such as digging holes for fence posts, planting trees, or installing various types of foundations. The gasoline engine provides the necessary power to turn the auger bit efficiently, making it suitable for heavy-duty and remote applications where access to electricity may be limited.

Gasoline Chain Saw

A Gasoline Chain Saw is a portable, mechanical cutting tool powered by an internal combustion engine that runs on gasoline. It typically consists of a chain with teeth attached to a guide bar, driven by the engine, and is commonly used for tasks such as tree felling, limb pruning, and wood cutting. The gasoline engine provides the necessary power to drive the chain, making the chainsaw a versatile tool for various outdoor cutting applications.

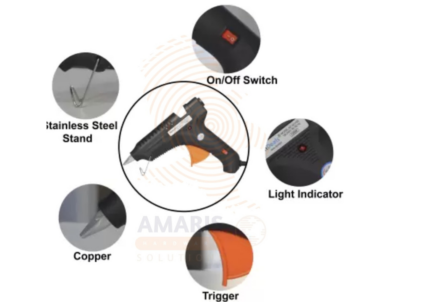

Glue Gun

A glue gun, specifically a 40-watt glue gun, is a handheld tool designed for dispensing hot melt adhesive in a controlled and precise manner. It typically consists of a heating element powered by a 40-watt electrical system, a trigger mechanism to control the adhesive flow, and a nozzle for directing the melted glue. The glue stick, usually made of thermoplastic materials, is inserted into the gun, melted by the heating element, and then extruded through the nozzle as a liquid adhesive. This versatile tool is commonly used in various DIY projects, crafts, and home repairs due to its quick and efficient bonding capabilities. The 40-watt power rating indicates the electrical power consumed by the glue gun to heat the adhesive to its melting point.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs