5 Piece Jig Saw Blade Set

$6,340.00 Original price was: $6,340.00.$5,840.00Current price is: $5,840.00.

Road Roller

WhatsApp Order

A road roller is a heavy construction vehicle equipped with a large, cylindrical metal drum or drums on its front and sometimes also on its rear. Its primary function is to compact and flatten surfaces, such as soil, asphalt, or concrete, during road construction or maintenance projects. The weight of the roller and the pressure exerted by its drums help to eliminate air voids and ensure a smooth, stable, and durable surface suitable for vehicular traffic.

SKU:

AHS21672

Category: Construction Machinery

Description

Road Roller Uses

- Road Construction: Road rollers are used extensively during road construction projects to compact soil, gravel, and asphalt layers. This ensures the stability and durability of the road surface.

- Pavement Maintenance: Road rollers are employed for pavement maintenance tasks such as repairing potholes, smoothing uneven surfaces, and sealing cracks. They help in preserving the integrity of existing roads and extending their lifespan.

- Asphalt Compaction: Asphalt rollers, a type of road roller specifically designed for asphalt compaction, are used to compress hot asphalt mixtures during road paving operations. This compaction ensures proper bonding and consolidation of the asphalt layers, resulting in a smooth and durable roadway.

- Land Development: Road rollers are utilized in land development projects to prepare the ground for construction by compacting soil and creating a stable foundation for buildings, parking lots, and other structures.

- Airport Construction: Road rollers play a crucial role in the construction of airport runways, taxiways, and aprons. They are used to compact soil and asphalt surfaces to meet the stringent requirements for aircraft operations.

- Industrial Sites: Road rollers are employed in industrial settings for compacting surfaces such as factory floors, storage yards, and container terminals. This helps in creating flat and stable surfaces conducive to material handling and equipment operation.

- Landscaping and Sports Field Construction: Road rollers are used in landscaping projects to flatten and compact surfaces for the construction of sports fields, recreational areas, and green spaces. They aid in creating level playing surfaces and promoting turf establishment.

Reviews (0)

Be the first to review “Road Roller” Cancel reply

Related products

Compactor

A compactor is a mechanical device or machine designed to compress and reduce the volume of various materials such as waste, trash, soil, or recyclables by applying pressure. Its primary function is to condense bulky materials into a more manageable size, making them easier to handle, transport, or dispose of efficiently. Compactors are commonly used in waste management, construction, landscaping, and manufacturing industries to optimize space utilization and streamline processes.

Concrete Mixer

A concrete mixer is a mechanical device used in construction to combine cement, aggregate (such as sand or gravel), and water into a homogenous mixture. This mixture is then used for various construction applications, such as pouring foundations, sidewalks, or driveways. Concrete mixers come in various sizes and designs, ranging from portable units for small-scale projects to large, stationary machines for industrial use.

Pavement Cutting Machine

A pavement cutting machine is a mechanical device used in construction and road maintenance to make precise cuts in asphalt, concrete, or other types of pavement surfaces. These machines typically feature a rotating circular blade or diamond-tipped blades that can cut through pavement with accuracy and efficiency. They are commonly employed for tasks such as repairing damaged pavement, installing utility lines, or creating expansion joints. Pavement cutting machines come in various sizes and configurations, ranging from handheld units for smaller projects to large, self-propelled machines for larger-scale operations.

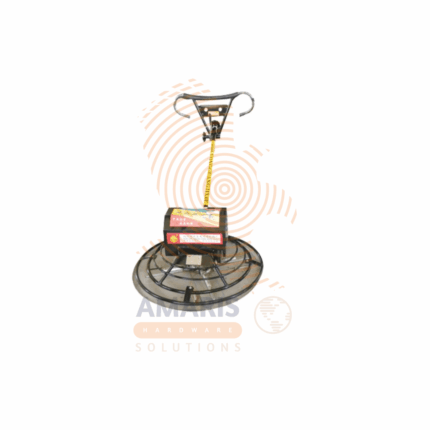

Pavement Trowelling

A pavement trowelling is a construction tool used in the finishing stages of laying pavement or concrete surfaces. It typically consists of a flat, rectangular metal blade attached to a handle. The trawler is used to smooth and level the surface of freshly poured concrete or pavement by pushing and pulling the tool across the surface. This helps to remove imperfections, create a uniform texture, and achieve the desired level of flatness for the final product.

Reinforcing Bar Bending Machine

A reinforcing bar bending machine is a specialized tool used in construction and civil engineering to bend steel reinforcement bars (rebar) accurately and efficiently according to specific project requirements. These machines typically consist of a sturdy frame, bending mechanism, and controls. They are designed to handle various sizes and shapes of rebar’s and can bend them to precise angles and configurations needed for reinforcing concrete structures such as beams, columns, and foundations. The primary purpose of these machines is to streamline the bending process, increase productivity, and ensure the structural integrity of reinforced concrete elements in construction projects

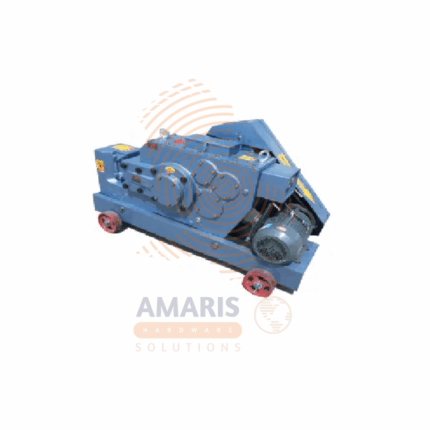

Reinforcing Bar Cutting Machine

A reinforcing bar cutting machine, also known as a rebar cutter, is a mechanical device designed to precisely cut steel reinforcement bars (rebar) used in construction projects. These machines typically operate by utilizing blades or other cutting mechanisms to shear through the steel bars with accuracy and efficiency. They are essential tools in construction sites where rebar cutting is a routine task, enabling workers to achieve precise cuts according to project specifications, enhancing safety, and improving overall productivity.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.