SDS - PH65 Stone Flat Chisel

$29.81 Original price was: $29.81.$28.32Current price is: $28.32.

Side Dumper

$5,780.77 Original price was: $5,780.77.$5,491.73Current price is: $5,491.73.

Sewage Pump

$80.77 Original price was: $80.77.$76.73Current price is: $76.73.

WhatsApp Order

A sewage pump is a submersible pump designed specifically to move wastewater and solid waste from one location to another, typically from a building’s sewage basin to a septic tank or sewer system. Engineered to handle solids-laden liquids, it is built with corrosion-resistant materials and robust impellers capable of processing human waste, sludge, and debris. Sewage pumps are commonly used in residential, commercial, and industrial sanitation systems, particularly where gravity flow is not possible. They are essential in managing waste efficiently, reducing health risks, and maintaining hygienic conditions.

Description

Table of Contents

ToggleSewage Pump

Uses

-

Domestic Sewage Management

o Transfers waste from basement bathrooms and laundry rooms to main sewage lines.

o Prevents backflow and flooding in low-lying residential areas. -

Septic System Assistance

o Pumps sewage into septic tanks where gravity cannot suffice.

o Ensures consistent flow in rural and off-grid systems. -

Commercial Wastewater Disposal

o Moves large volumes of sewage in commercial properties like restaurants and malls.

o Handles high loads and heavy-duty operations. -

Industrial Effluent Transfer

o Removes liquid waste and sludge from factories or processing plants.

o Supports safe and compliant waste disposal operations. -

Stormwater and Flood Control

o Assists in pumping floodwater mixed with debris from basements or garages.

o Prevents waterlogging and structural damage. -

Municipal Sewage Systems

o Transfers sewage from collection points to treatment facilities.

o Used in lift stations and urban sewer networks. -

Wastewater Treatment Plants

o Handles raw sewage inflow in the initial stages of treatment.

o Facilitates sedimentation and filtration processes. -

Agricultural Waste Handling

o Pumps slurry and animal waste in livestock farms.

o Helps manage sanitation and fertilization systems. -

Construction Site Drainage

o Removes wastewater and contaminated water from trenches and pits.

o Maintains dry and safe working environments.

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Wear Protective Equipment

o Use gloves, goggles, and boots to protect from contaminants. -

Disconnect Power Before Maintenance

o Turn off and unplug the unit before inspection or cleaning. -

Avoid Direct Contact with Waste

o Do not touch sewage water directly; always use tools or PPE. -

Ensure Proper Ventilation

o Operate in well-ventilated areas to avoid harmful gas buildup. -

Install Backflow Prevention

o Use check valves to prevent reverse flow of sewage. -

Regularly Inspect Pump Components

o Check for blockages, impeller damage, and motor wear. -

Do Not Overload the Pump

o Ensure pump capacity matches application requirements. -

Use Ground Fault Circuit Interrupters (GFCI)

o Protect against electric shock in wet environments. -

Secure the Pump During Operation

o Ensure proper positioning and secure mounting to prevent tipping or movement.

Related products

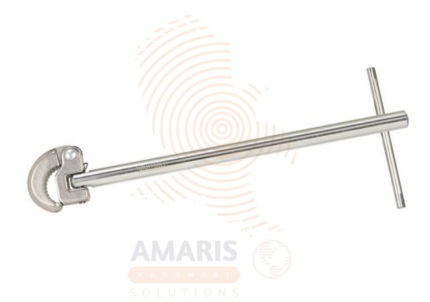

Basin Wrench with Fixable Head

A Basin Wrench with Fixable Head is a specialized plumbing tool designed for the installation and removal of nuts in confined spaces, particularly in and around basins and sinks. The tool features an adjustable and fixable head, allowing the user to set it at different angles for versatile use in tight quarters. The wrench typically has a long handle and a pivoting jaw with a spring-loaded mechanism, enabling it to grip and turn nuts located in hard-to-reach areas. The fixable head feature ensures stability and ease of use, making it a valuable tool for plumbing tasks in areas with limited access.

Electric Submersible Pump

An electric submersible pump (ESP) is a pump designed to operate while fully submerged in water or other fluids. It uses an electric motor sealed within a watertight casing to push fluid to the surface, making it ideal for draining, irrigation, sewage treatment, and various industrial applications. ESPs are valued for their efficiency, reliability, and ability to handle deep water extraction, providing a steady flow even from significant depths.

Oil Expeller

An Oil Expeller is a mechanical device used to extract oil from oil-bearing seeds and nuts through a process of high-pressure mechanical pressing. It typically consists of a screw shaft, pressing chamber, and power system (manual, electric, or engine-driven), and is widely used in small-scale farms, local oil mills, and commercial processing units. Capable of handling materials like sunflower seeds, groundnuts, soybeans, mustard, coconut, and sesame, oil expellers are available in both cold press and hot press variants. This machine enables efficient, chemical-free oil extraction, producing unrefined oil and residual seed cake for further use.

Pipe Cutter

A pipe cutter is a specialized tool designed for cutting pipes cleanly and accurately. Typically used in plumbing and other pipe-related applications, a pipe cutter consists of a cutting wheel or blade that is rotated around the pipe's circumference, gradually creating a groove. The tool is then tightened or adjusted, and the cutting wheel is rotated again, gradually deepening the groove until the pipe is cleanly severed. Pipe cutters come in various designs, including manual, ratcheting, and powered versions, providing versatility for different pipe materials and sizes.

PPR Welding Machine

A PPR welding machine, specifically designed for polypropylene random copolymer (PPR) pipes, is a device used to join these pipes securely and effectively through the application of heat. The machine typically utilizes a combination of heat and pressure to melt the ends of the PPR pipes, allowing them to fuse together and form a strong, durable connection. This process is known as heat fusion or thermo fusion welding.

The PPR welding machine generally consists of a heating element, temperature control mechanisms, and clamping devices to hold the pipes in place during the welding process. It ensures the creation of leak-proof joints, making it a vital tool in plumbing, construction, and other applications where PPR pipes are used for conveying fluids.

Pump Sprayer

A pump sprayer, also known as a hand pump sprayer or pressure sprayer, is a manually operated device designed for spraying liquids such as pesticides, herbicides, fertilizers, cleaning solutions, or water. It typically consists of a container to hold the liquid, a pump mechanism to pressurize the container, a wand or nozzle for directing the spray, and a handle for pumping and carrying. Users pressurize the container by manually pumping the handle, creating pressure that allows the liquid to be sprayed in a controlled manner when the nozzle is activated. Pump sprayers are commonly used in gardening, agriculture, pest control, and various household applications for targeted and even distribution of liquids.

Sewage submersible pump

A sewage submersible pump is a specialized type of pump designed for the efficient and reliable transfer of wastewater, sewage, or other contaminated fluids from one location to another. Unlike traditional pumps that are installed above ground, sewage submersible pumps are designed to be submerged in the fluid they are pumping. This submersible design allows the pump to operate efficiently in challenging environments, such as sewage systems, septic tanks, or other applications where the fluid may contain solids or debris.

These pumps are typically sealed to prevent water or sewage from entering the motor and other internal components. They often feature robust construction and materials to withstand the corrosive and abrasive nature of sewage. Sewage submersible pumps play a crucial role in wastewater management, helping to transport sewage from homes, businesses, and industrial facilities to treatment plants or disposal sites.

Submersible Clean Water Pump

A submersible clean water pump is a specialized electric pump designed to be fully submerged in water, typically for the purpose of transferring or circulating clean water. Unlike surface pumps, these devices are specifically engineered to operate underwater, effectively drawing water from the source and then discharging it to another location. Submersible clean water pumps are commonly used in various applications such as residential water supply, irrigation, drainage, and fountain systems, where the water being handled is free from debris or contaminants. These pumps are sealed to prevent water from entering the internal components, ensuring safe and efficient operation when submerged.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs