Stone Crusher

$ 665.38 Original price was: $ 665.38.$ 632.11Current price is: $ 632.11.

Stoning Hammer - Wood Handle

$ 24.81 Original price was: $ 24.81.$ 23.57Current price is: $ 23.57.

Stone Separator

$ 780.77 Original price was: $ 780.77.$ 741.73Current price is: $ 741.73.

WhatsApp Order

A stone separator is an agricultural or industrial machine designed to remove stones and other unwanted materials from grains, seeds, soil, or construction aggregates. Using vibration, airflow, or gravity-based separation methods, it ensures cleaner, higher-quality end products. Stone separators are commonly used in farming, food processing, milling, and construction to improve operational efficiency and prevent equipment damage from hard debris.

Description

Table of Contents

ToggleStone Separator

Uses

-

Grain Cleaning

o Removes stones and heavy impurities from harvested grains like wheat, rice, and maize.

o Enhances grain quality before milling or packaging. -

Seed Processing

o Separates unwanted stones and debris from seed batches to ensure purity.

o Protects seed drills and planters from mechanical damage. -

Soil and Compost Refining

o Removes rocks from soil or compost used in agriculture and landscaping.

o Ensures smoother tilling and planting. -

Construction Aggregate Sorting

o Eliminates unwanted debris from sand, gravel, or crushed materials before use in construction.

o Enhances material uniformity and structural integrity. -

Milling and Flour Production

o Ensures stone-free grains enter milling systems to prevent contamination or machine damage.

o Increases safety and cleanliness in food-grade operations. -

Animal Feed Preparation

o Prepares cleaner feedstock by removing dense contaminants.

o Prevents harm to livestock and feed processing equipment. -

Mining and Quarrying Support

o Assists in pre-sorting raw material by eliminating non-valuable stones.

o Improves downstream processing efficiency. -

Waste Sorting and Recycling

o Separates heavy particles or rubble from recyclables in waste management systems.

o Reduces equipment wear and increases material recovery. -

Gardening and Landscaping

o Refines soil or planting media by filtering out pebbles and rocks.

o Prepares surfaces for turfing or planting.

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Wear Dust and Eye Protection

o Use safety goggles and dust masks when operating in dry, dusty environments. -

Keep Hands Away from Moving Parts

o Avoid injuries by keeping clear of vibrating or rotating mechanisms. -

Secure and Level the Machine

o Operate on flat, stable surfaces to prevent tipping or vibrations. -

Regular Maintenance and Cleaning

o Clean sieves and components to ensure consistent performance and avoid clogging. -

Use in Well-Ventilated Areas

o Prevent buildup of dust and ensure proper airflow for machines using air separation. -

Shut Down Before Servicing

o Always turn off the machine before cleaning, adjusting, or inspecting. -

Proper Operator Training

o Ensure users understand the controls and purpose of the machine. -

Avoid Overloading

o Feed material in controlled amounts to prevent blockages and uneven separation. -

Electrical Safety

o For electric-powered models, check wiring and grounding before use.

Related products

Bi-Metal Hole Saw

A Bi-Metal Hole Saw Set refers to a collection of nine hole saws, each constructed with a bi-metal design. A hole saw is a cylindrical cutting tool used to create holes in various materials such as wood, metal, plastic, and more. The term "bi-metal" indicates that the hole saws are made from two different types of metals, typically high-speed steel (HSS) and a more durable alloy like cobalt. This combination enhances the hole saw's cutting performance, making it suitable for a wide range of applications and providing increased durability and longevity. The set typically includes hole saws of different sizes to accommodate various hole diameters, making it a versatile tool for professionals and DIY enthusiasts alike.

Die Set

An Die Set typically refers to an 8-piece die set used in various manufacturing and machining processes. In manufacturing and metalworking, dies are specialized tools used to shape, cut, or form materials such as metal, plastic, or other substances. A die set, in this context, is a collection of individual dies designed to work together for specific tasks.

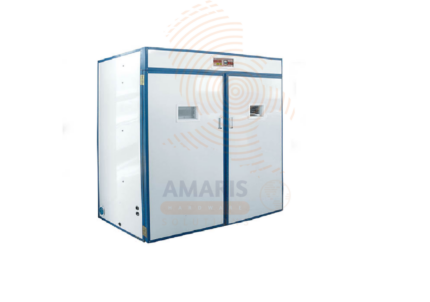

Egg Incubator

An egg incubator is a specialized device designed to artificially hatch eggs by maintaining optimal temperature, humidity, and ventilation conditions. This equipment simulates the natural environment provided by brooding birds, ensuring consistent warmth and air circulation to promote healthy embryo development. Egg incubators are widely used in poultry farming, hatcheries, research, and educational settings to increase hatch rates, control breeding cycles, and improve the efficiency of egg hatching processes.

German Type Grease Gun

A "German type grease gun" typically refers to a type of grease gun that is of German origin or follows a design influenced by German engineering. A grease gun is a handheld tool used in automotive and industrial settings to apply lubricating grease to machinery or equipment. The term "German type" may indicate that the grease gun follows design principles, specifications, or standards commonly associated with German engineering. German engineering is often associated with precision, durability, and high-quality manufacturing. Therefore, a German type grease gun may be expected to exhibit these characteristics. It's worth noting that specific details about a "German type grease gun" may vary, and the term may be used loosely to refer to any grease gun with characteristics reminiscent of German design principles.

Hose for Air Compressor

A Hose for Air Compressor is a flexible and durable conduit designed to connect the air compressor to pneumatic tools, equipment, or other devices requiring compressed air. Typically made of materials such as rubber, PVC, or hybrid blends, these hoses are capable of withstanding high pressure and provide a pathway for the compressed air to flow from the compressor to the intended application. The hose facilitates the efficient and controlled transfer of compressed air, enabling various pneumatic tools and devices to operate effectively in a wide range of industrial, automotive, and household applications.

Oil Pot

Pedestal Grinder

A Pedestal Grinder is a robust, stationary grinding machine mounted on a pedestal stand and designed for heavy-duty grinding, sharpening, shaping, and polishing tasks. It typically features two grinding wheels—coarse and fine—on either end of a motor-driven shaft. Widely used in workshops, fabrication units, and maintenance departments, pedestal grinders are ideal for sharpening tools, removing burrs, cleaning welds, and refining metal components. The fixed design ensures stability, while adjustable tool rests and safety guards enhance control and operator protection during high-speed grinding operations.

Spray Gun & Air Tool Accessory Kit Set

A Spray Gun & Air Tool Accessory Kit Set typically refers to a package or bundle that includes five essential components or accessories designed to complement and enhance the functionality of spray guns and air tools. These kits are commonly used in various applications, such as automotive painting, woodworking, and other projects where spray painting or air-powered tools are employed. The specific contents of the kit may vary, but it often includes items such as different nozzle attachments, connectors, air hoses, and other accessories necessary for optimal performance and versatility with spray guns and air tools. The aim is to provide users with a comprehensive set of tools and accessories to meet their diverse needs in a convenient and cost-effective manner.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs