“BI-Metal Hole Saw Positioning Drill” has been added to your cart. View cart

Uyus Brick Trowel

$6,040.00 Original price was: $6,040.00.$5,540.00Current price is: $5,540.00.

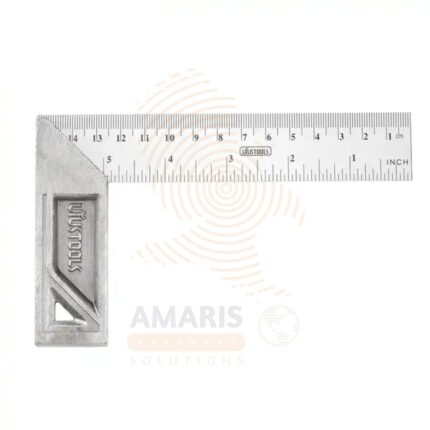

Heavy-duty Try Square

$5,800.00 Original price was: $5,800.00.$5,300.00Current price is: $5,300.00.

Twist Wire Bevel Brush – Metric

$9,640.00 Original price was: $9,640.00.$9,140.00Current price is: $9,140.00.

WhatsApp Order

- Twist Wire: This likely refers to the type of bristle or filament used in the brush. “Twist wire” suggests that the bristles are made by twisting wires together, which can provide durability and stiffness.

- Bevel Brush: A bevel brush typically has bristles that are set at an angle to the brush surface. This design allows for more effective cleaning or brushing in certain applications, especially where precision or reaching corners is important.

- Metric for Hardware Use: The term “metric” implies that the brush is designed or measured using the metric system, which is common in many countries around the world. “For hardware use” indicates that the brush is intended for applications in the hardware industry.

A twist wire bevel brush – metric is a type of brush with bristles made by twisting wires, set at an angle for more effective cleaning, and designed with metric measurements for use in hardware-related applications. It is used for tasks like cleaning, deburring, or surface preparation in the hardware or manufacturing industry.

SKU:

AHS38347-1

Category: Power Tool Accessories

Description

Twist wire bevel brush – metric uses

- Surface Cleaning and Preparation: These brushes can be used for cleaning and preparing surfaces, particularly in metalworking or woodworking. The twisted wire bristles can help remove rust, paint, scale, and other debris from surfaces.

- Deburring: The abrasive nature of the twisted wire bristles makes these brushes suitable for deburring rough edges on metal or plastic materials.

- Weld Cleaning: In welding applications, these brushes can be employed to clean and prepare welded joints. The bevel design may assist in reaching tight spaces and corners.

- Rust Removal: The stiff bristles can be effective in removing rust and corrosion from metal surfaces, making them useful for maintenance tasks.

- Polishing and Finishing: Depending on the brush’s design and the materials used, it may be suitable for polishing and finishing surfaces, providing a smooth and even finish.

- Industrial Equipment Maintenance: These brushes could be utilized in the maintenance of machinery and equipment in various industries, helping to clean and prepare parts for optimal functioning.

- Heavy-Duty Cleaning: The robust nature of twist wire bevel brushes makes them suitable for heavy-duty cleaning tasks, such as cleaning industrial equipment, machinery, or parts.

- Material Removal: These brushes can assist in removing unwanted material from surfaces, making them valuable in applications where precision is required.

Reviews (0)

Be the first to review “Twist Wire Bevel Brush – Metric” Cancel reply

Related products

Arbor

an arbor is a cylindrical metal shaft or spindle that is typically used in conjunction with various tools and equipment. It often serves as a central axis onto which other components, such as blades, grinding wheels, or drill bits, can be attached. Arbors are commonly found in tools like saws, grinders, and drills, facilitating the secure mounting and rotation of cutting or abrasive elements. They play a crucial role in providing stability and precision during the operation of such tools, ensuring efficient and controlled performance.

Chain Saw Adapter for Angle Grinder

An chain saw adapter typically refers to a device or accessory that enables the use of a grinder with a 12-inch chainsaw. This adapter serves as an interface between the chainsaw and the grinder, allowing them to be connected or integrated seamlessly. The primary purpose of such an adapter is to enhance the functionality of the chainsaw by facilitating the attachment of a grinder, which can be used for sharpening or modifying the chainsaw chain. This adaptability provides users with the convenience of performing maintenance tasks and optimizing the cutting performance of the chainsaw.

Diamond Cutting Blade (Turbo) – Cold Press

Diamond Cutting Blade (Turbo) – Cold Press is a specialized tool used in construction and masonry for cutting hard materials such as concrete, granite, marble, or other similar substances. The term "Turbo" typically refers to the design of the blade, featuring a segmented rim with narrow gullets or slots that aid in cooling and debris removal during the cutting process.

The "Cold Press" aspect indicates the manufacturing process used to create the diamond blade. In a cold press method, the diamond segments are pressed and sintered at lower temperatures, resulting in a blade with a different structure compared to hot-pressed blades. Cold press blades are known for their durability and ability to withstand high temperatures during prolonged use.

Drill, Chuck & Key

A drill, chuck & key is a device that holds and tightens the drill bit in place during drilling operations. It is typically mounted on the spindle of a drill or similar power tool. The chuck consists of movable jaws that can be adjusted to grip the shank of the drill bit securely. This allows the drill bit to rotate with the spindle, enabling effective drilling.

A chuck key is a tool used to tighten or loosen the jaws of the drill chuck. It usually has a T-shaped or L-shaped handle that fits into a corresponding socket on the chuck. By turning the key, the jaws of the chuck either move closer together to grip the drill bit or move apart to release it. The chuck key is essential for securing the drill bit in place and adjusting the chuck's grip to accommodate different sizes of drill bits.

Electric Drill Stand

The Electric Drill Stand transforms your handheld drill into a stable, vertical drilling machine for accurate, repeatable results. Perfect for woodworking, metalwork, electronics, and DIY projects, it ensures safer, straighter holes with improved depth control. Ideal for hobbyists and professionals alike, this compact stand boosts precision and productivity in any workshop setup.

Flat Knotted Wire Wheel

A flat knotted wire wheel refers to a rotating tool used in various applications, typically in metalworking and surface preparation. It consists of a wheel-shaped assembly with wire bristles that are tightly twisted or "knotted" together. The wire bristles can be made of steel or other durable materials, and they are arranged in a radial pattern around the wheel.

Knotted wire wheels are commonly attached to power tools such as angle grinders or bench grinders. They are employed for tasks like removing rust, paint, scale, or other surface contaminants from metal surfaces, as well as for deburring or blending welds. The tightly twisted configuration of the wire bristles enhances the wheel's durability and effectiveness in tackling tough materials and applications.

These wheels are available in various sizes and designs to suit different tasks, and they are known for their abrasive action, making them valuable tools in metal fabrication, construction, and maintenance work.

SDS Plus Stone Flat Chisel

An SDS-PLUS stone flat chisel is a specialized tool designed for use with SDS-PLUS rotary hammer drills. It is a flat-edged chisel specifically crafted for masonry and stone applications. The SDS-PLUS shank refers to the type of chuck connection that allows for quick and secure tool changes in compatible rotary hammer drills. The flat chisel design is ideal for tasks such as chipping, carving, and shaping stone or masonry surfaces. This tool is commonly used in construction and renovation projects where precision and efficiency in working with hard materials are essential.

SDS Plus Stone Pointed Chisel

An SDS-PLUS stone pointed chisel is a specialized masonry tool designed for use with rotary hammer drills that feature the SDS-PLUS chuck system. This chisel has a pointed tip specifically crafted for effective and precise material removal in stonework, concrete, or similar hard surfaces. The SDS-PLUS system allows for quick and secure attachment of the chisel to the drill, ensuring efficient chiseling and reducing the likelihood of slippage during operation. The stone pointed chisel is commonly employed in tasks such as carving, shaping, or breaking hard materials in construction and masonry applications.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.