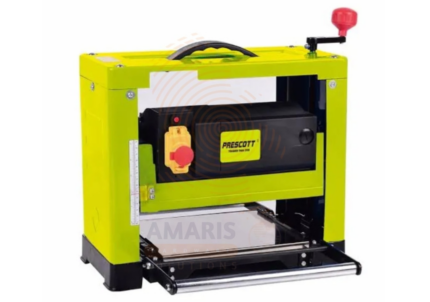

Thickness Planner Blade

$20.77 Original price was: $20.77.$19.73Current price is: $19.73.

A Thickness Planner Blade is a cutting tool specifically designed for use in a thickness planer machine. The thickness planer is a woodworking tool used to reduce the thickness of a work piece, such as a board or plank, by consistently shaving off thin layers of material. The planer blade, often made of high-speed steel or carbide, is a sharp and durable cutting edge that rotates at high speeds within the planer. Its primary function is to remove excess material from the surface of the work piece, resulting in a smooth and uniform thickness across the entire piece. The quality and sharpness of the thickness planer blade significantly impact the precision and finish of the planed surface.

Table of Contents

ToggleThickness Planner Blade

Uses

-

Material Thickness Reduction:

-

The primary purpose of a thickness planer blade is to reduce the thickness of a wooden work piece. By feeding the material through the planer, the blade removes thin layers, providing a consistent and smooth surface.

-

-

Surface Smoothing:

-

Thickness planers are effective in smoothing rough surfaces and eliminating imperfections, such as unevenness, snipe, or rough saw marks. The blade plays a key role in achieving a polished and even finish.

-

-

Dimensional Consistency:

-

Woodworkers use thickness planers to ensure uniform thickness across a board or plank. This is particularly important when working on projects that require precise dimensions for a professional and aesthetically pleasing result.

-

-

Creating Parallel Surfaces:

-

Thickness planers are essential for creating parallel surfaces on wooden pieces. This is important for joinery work, where two or more pieces need to fit together seamlessly.

-

-

Material Cleanup:

-

When working with reclaimed or rough-sawn lumber, a thickness planer is employed to clean up and refine the surfaces. The blade removes any irregularities, knots, or other defects in the material.

-

-

Customizing Stock Thickness:

-

Woodworkers often need to customize the thickness of stock material to meet specific project requirements. The thickness planer blade facilitates this customization by allowing precise adjustments to the material thickness.

-

-

Creating Consistent Panels:

-

In cabinet making and furniture construction, thickness planers are used to create consistent thickness across multiple boards, ensuring that panels or components fit together seamlessly.

-

-

Enhancing Woodworking Efficiency:

-

Using a thickness planer speeds up the woodworking process by quickly and efficiently reducing the thickness of material. This is especially important when dealing with large quantities of lumber.

-

-

Preparing Stock for Further Processing:

-

Before additional woodworking processes, such as joinery, gluing, or shaping, the thickness planer is often used to prepare the stock material, providing a clean and uniform starting point for subsequent work.

-

Safety Precautions

-

Protective Gear:

-

Eye Protection: Always wear safety glasses or goggles to protect your eyes from flying wood chips and debris.

-

Hearing Protection: Use earplugs or earmuffs to protect your hearing when operating the planer.

-

Personal Protective Equipment (PPE): Wear gloves to protect your hands when handling blades, and avoid loose clothing or jewelry that could get caught.

-

Read the Manual:

-

Familiarize yourself with the planer’s user manual, especially the blade installation and maintenance instructions.

-

Blade Handling:

-

Handle blades carefully to avoid cuts; always hold blades by the edges, not the cutting surface.

-

Ensure blades are properly installed, secured, and aligned before operation.

-

Secure Work Area:

-

Keep the workspace clean and well-lit.

-

Remove any obstacles or loose objects near the planer.

-

Power Off Before Maintenance:

-

Always disconnect power before changing or servicing blades.

-

Proper Installation:

-

Use the correct blades specified for your planer model.

-

Verify that blades are sharp and free from damage to prevent kickback or poor cuts.

-

Stable Position:

-

Stand firmly and maintain balance when feeding wood into the planer.

-

Avoid Overreach:

-

Do not reach into the planer while it is running.

-

Ventilation:

-

Work in a well-ventilated area to avoid inhaling wood dust.

-

Emergency Preparedness:

-

Know the location of emergency stops and first aid supplies.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors and Accessories: Belts and Rollers

Conveyors and Accessories: Belts and Rollers