Reciprocating Saw

$61.54 Original price was: $61.54.$58.46Current price is: $58.46.

Riveter

$21.81 Original price was: $21.81.$20.72Current price is: $20.72.

Rivet

$13.35 Original price was: $13.35.$12.68Current price is: $12.68.

WhatsApp Order

A rivet is a permanent mechanical fastener consisting of a cylindrical shaft with a head at one end. During installation, the shaft is passed through aligned holes in two or more pieces of material, and then the other end of the shaft is deformed to create a second head, effectively creating a secure and tight joint. Rivets are commonly used to fasten and join materials like metal sheets, plates, or components where a strong, durable, and vibration-resistant connection is required. They come in various types, such as solid, blind, and pop rivets, each suited to specific applications and installation conditions.

Description

Table of Contents

ToggleRivet

Uses

-

Aerospace Industry:

-

Rivets are extensively used in the aerospace industry to join aluminum and other lightweight materials in the construction of aircraft structures. They help create strong and durable connections while maintaining a low overall weight.

-

-

Automotive Industry:

-

Rivets are used in automotive manufacturing for joining components like body panels, frames, and other structural elements. They provide a secure and durable connection in areas that may experience significant stress and vibration.

-

-

Construction and Building:

-

In the construction industry, rivets are employed to connect structural steel elements, bridge components, and architectural features. They offer a reliable solution for joining materials that need to withstand the forces associated with buildings and infrastructure.

-

-

Shipbuilding:

-

Rivets have historical significance in shipbuilding, and although welding has become more common, rivets are still used in some marine applications. They help secure various components in the construction of ships and boats.

-

-

Railroad Industry:

-

Rivets are utilized in the assembly of railway cars and tracks. They provide a strong and durable connection that can withstand the constant vibrations and loads experienced in the rail industry.

-

-

Electronic and Electrical Devices:

-

Rivets are used in the assembly of electronic and electrical devices. They help secure components in place and provide a stable connection in applications where welding or screws may not be suitable.

-

-

Leather Goods and Fashion:

-

In the manufacturing of leather goods and fashion accessories, rivets are commonly used for decorative and functional purposes. They can be found in items such as belts, bags, and footwear.

-

-

DIY and Home Repairs:

-

Rivets are used in DIY projects and home repairs for fastening and joining materials. They are commonly employed in tasks like attaching metal brackets, reinforcing structures, and repairing or assembling various household items.

-

-

Military and Defense:

-

In military and defense applications, rivets are used to assemble and connect components in equipment, vehicles, and structures. They contribute to the overall strength and reliability of these systems.

-

-

HVAC Systems:

-

Rivets are used in the assembly of heating, ventilation, and air conditioning (HVAC) systems. They provide a secure and lasting connection in the fabrication of ductwork and other components.

-

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Personal Protective Equipment (PPE):

-

Wear appropriate PPE, including safety glasses or goggles to protect your eyes from flying debris, and gloves to shield your hands from sharp edges and potential injury during the riveting process.

-

-

Ear Protection:

-

In situations where loud or repetitive noise may occur during the riveting process, consider using ear protection, such as earplugs or earmuffs, to prevent hearing damage.

-

-

Ventilation:

-

Work in well-ventilated areas to avoid the inhalation of fumes or particles generated during the riveting process. If working in confined spaces, ensure adequate ventilation or use respiratory protection when necessary.

-

-

Secure Work Area:

-

Ensure that the work area is clean, well-organized, and free from obstacles. This helps prevent tripping hazards and allows for better control of the riveting tools.

-

-

Tool Inspection:

-

Regularly inspect and maintain riveting tools, ensuring they are in good working condition. Replace any damaged or worn-out parts promptly to prevent accidents and ensure the effectiveness of the tools.

-

-

Proper Training:

-

Provide adequate training to individuals using riveting tools. Ensure they are familiar with the correct procedures, techniques, and safety precautions associated with rivet installation.

-

-

Correct Tool for the Job:

-

Use the appropriate type and size of rivet for the specific application. Using the wrong rivet or tool may compromise the strength of the joint and pose safety risks.

-

-

Secure Materials:

-

Secure the materials being riveted properly to prevent movement or displacement during the riveting process. This helps ensure accurate placement of the rivets and reduces the risk of injury.

-

-

Proper Body Positioning:

-

Maintain proper body positioning during riveting. Avoid awkward postures that could lead to strain or discomfort. Ensure a stable footing, and use support or bracing when needed.

-

-

First Aid Kit:

-

Keep a well-stocked first aid kit nearby in case of minor injuries. Be aware of the location of emergency exits and equipment for more serious incidents.

-

-

Follow Manufacturer Guidelines:

-

Adhere to the manufacturer's guidelines and recommendations for the specific riveting tools and equipment being used. This includes understanding the correct operating procedures and any safety precautions outlined in the user manual.

-

Related products

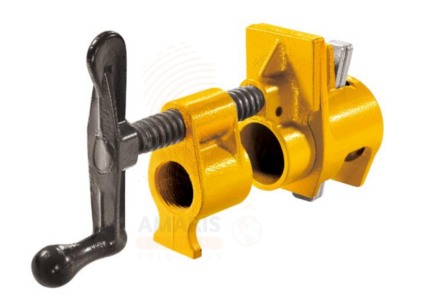

Heavy Duty Pipe Clamp

A Heavy Duty Pipe Clamp is a robust fastening device designed to securely hold pipes and cylindrical workpieces during assembly, welding, gluing, or cutting operations. Constructed from high-strength materials such as cast iron or steel, it consists of adjustable jaws that grip around pipes, often using a threaded screw mechanism to apply precise clamping pressure. These clamps are essential in metalworking, plumbing, woodworking, and industrial fabrication tasks, where stability and alignment are critical. The heavy-duty variant is capable of withstanding high pressure and torque, ensuring the pipe remains stationary during demanding tasks.

HSS Drill Bit

A HSS Drill Bit (High-Speed Steel), is a cutting tool designed for drilling holes in various materials, including metal, wood, plastic, and composites. It is made from high-speed steel, a type of alloy that contains tungsten, molybdenum, chromium, and vanadium, which enhances its hardness, heat resistance, and durability. HSS drill bits are known for their ability to withstand high temperatures generated during drilling and maintain sharp cutting edges, making them suitable for a wide range of drilling applications in industrial, construction, and DIY settings.

HSS Twist Drill

A High-Speed Steel (HSS) Twist Drill Bits Set refers to a collection of drill bits made from high-speed steel, a type of tool steel that is designed to withstand high temperatures and offer excellent hardness and durability. Twist drill bits are characterized by their helical (spiral) grooves that help to efficiently remove material as they penetrate into the work piece. HSS drill bits are commonly used for drilling into various materials, including metals, wood, and plastics. The set typically includes a range of drill bit sizes to accommodate different drilling needs, providing versatility for various projects and applications. HSS twist drill bits are favored for their ability to maintain sharpness at elevated temperatures, making them suitable for tasks that involve high-speed drilling and heavy-duty applications.

HSS Twist Drill Bits Set

An HSS Twist Drill Bits Set typically refers to a collection of eight individual drill bits made from high-speed steel, a type of tool steel known for its durability and ability to withstand high temperatures generated during drilling. The term "twist" in "twist drill bits" refers to the helical or spiral shape of the cutting edges.

These sets usually come in a variety of sizes, allowing users to choose the appropriate bit for different drilling applications. The set may include bits with varying diameters, enabling users to drill holes of different sizes in materials like wood, metal, plastic, and other common materials.

In summary, an 8pcs HSS Twist Drill Bits Set is a versatile tool kit that provides a selection of high-quality drill bits suitable for a range of drilling tasks in various materials.

S-Clamp

An S-Clamp is a versatile clamping tool shaped like the letter “S,” used for holding, positioning, or securing workpieces during various tasks such as gluing, welding, cutting, or assembly. It features dual clamping jaws that provide pressure from opposite ends, making it suitable for woodworking, metalworking, and general workshop use. Its compact design allows for use in tight or irregular spaces where other clamps may not fit, providing firm grip and alignment.

Screw Plug

A screw plug typically refers to a threaded, cylindrical device designed to be inserted into a hole or opening, primarily for the purpose of sealing, closing, or securing the opening. The threaded design allows the screw plug to be easily screwed into or out of the hole, providing a simple and effective means of closure. Screw plugs are commonly used in various applications, such as plumbing, machinery, and equipment, where they serve to prevent the leakage of liquids or gases, protect internal components, or facilitate access for maintenance and inspection.

Spring Clamp – Dual Color

A spring clamp - dual color is a hand-operated clamping tool designed to provide quick, firm, and temporary holding pressure on materials. It features strong spring tension for gripping, typically used in woodworking, crafting, photography, and light-duty construction. The dual-color design enhances visibility and differentiates size or strength variants. Made with durable plastic or metal and pivoting jaws, it provides secure and non-marring clamping on uneven surfaces.

Staples

Staples" generally refer to fasteners used to join or secure materials together. These staples are typically U-shaped or T-shaped metal pieces designed to be driven into a surface to hold objects in place. They are commonly used in construction, carpentry, and other applications to fasten materials like wood, fabric, or wire. The staples are driven into the material using a staple gun or a similar device. The primary purpose of hardware staples is to create a secure and durable connection between materials, making them an essential tool in various building and repair tasks.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs