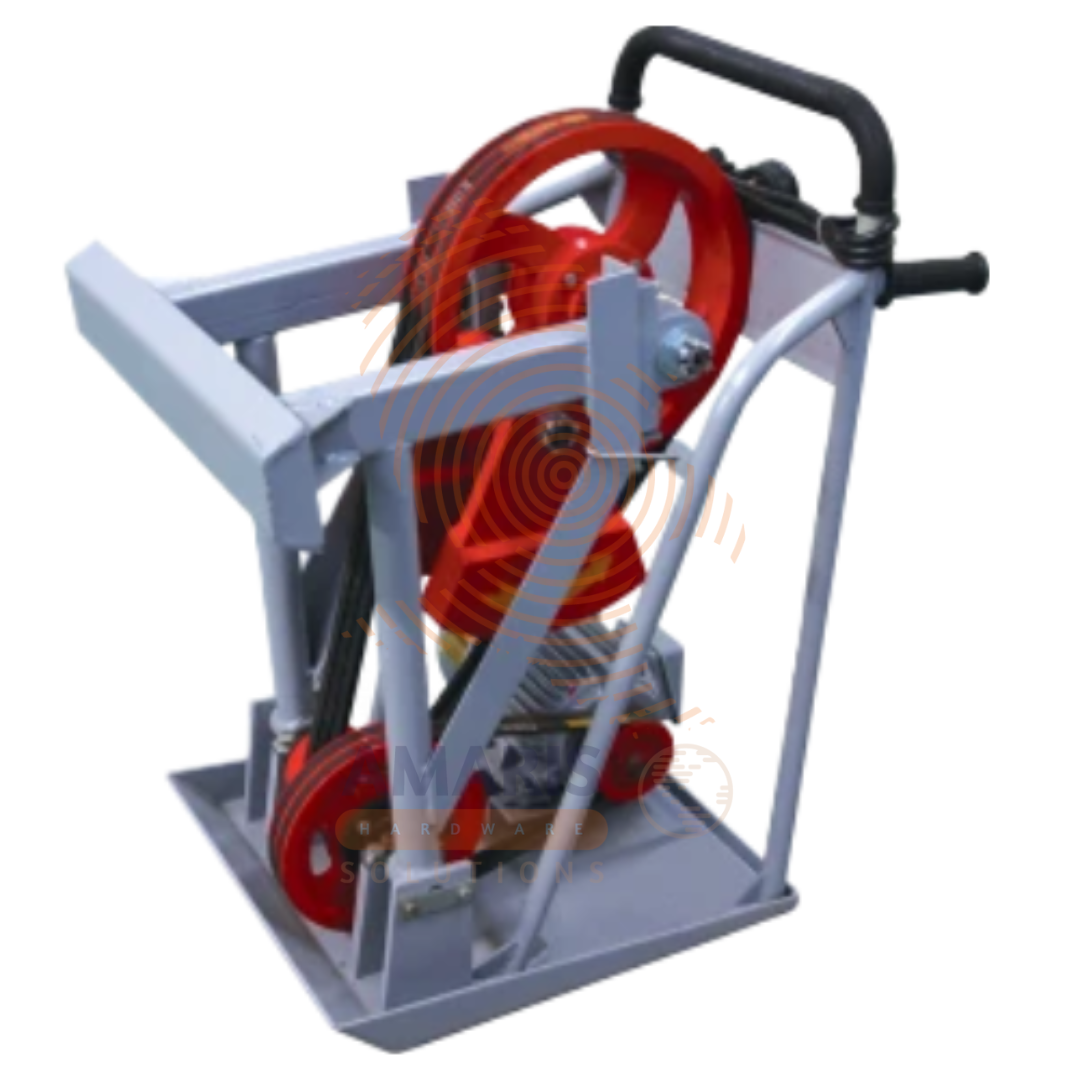

Frog Tamping Rammer

$650.00 Original price was: $650.00.$617.50Current price is: $617.50.

A Frog Tamping Rammer is a compact, high-impact compaction machine used in construction for compacting soil, gravel, and sand in confined or hard-to-reach areas. Unlike larger plate or roller compactors, this rammer delivers a powerful vertical force through a narrow, foot-like base (hence the name “frog”) to compact cohesive and granular soils. Commonly powered by gasoline or diesel engines, it is ideal for trench work, pipeline backfilling, foundations, road repairs, and other applications where precision and deep compaction are essential. Known for its portability and high compaction force, the frog rammer is indispensable in urban construction, civil engineering, and landscaping projects.

Table of Contents

ToggleFrog Tamping Rammer

Uses

-

Trench Compaction

o Ideal for compacting narrow trenches after pipe or cable installation.

o Prevents settling or shifting by ensuring solid backfill. -

Pipeline and Utility Installation

o Compacts backfill around sewer, water, gas, or electrical lines.

o Helps prevent erosion and protects against pipe misalignment. -

Foundation Preparation

o Ensures compact and stable soil under concrete footings, slabs, and walls.

o Reduces the risk of future structural failure due to shifting soil. -

Road and Pavement Repair

o Used in patching potholes or reconstructing small sections of road.

o Provides compact base for asphalt or concrete overlays. -

Confined Area Compaction

o Perfect for tight spaces where larger compactors cannot operate.

o Useful in urban sites, alleyways, or between structural elements. -

Landscaping and Hardscaping

o Compacts soil or sand beneath patios, retaining walls, and garden beds.

o Helps maintain the integrity of outdoor installations over time. -

Backfilling Around Structures

o Ensures soil is tightly packed around foundations, basements, or retaining walls.

o Prevents water infiltration and soil movement. -

Railway and Track Maintenance

o Used to compact ballast and soil around railroad ties and switches.

o Supports rail stability and minimizes vibrations. -

Compaction in Seismic Zones

o Densifies soil in earthquake-prone regions to reduce liquefaction risk.

o Enhances ground stability in infrastructure projects.

Safety Precautions

-

Wear Protective Gear

o Always wear hearing protection due to high noise levels.

o Use safety goggles, gloves, and steel-toed boots to protect against debris and vibration.

o Wear a dust mask or respirator when working in dry or enclosed environments. -

Inspect Equipment Before Use

o Check for oil or fuel leaks, loose bolts, and damaged components.

o Ensure the throttle, air filter, and footplate are clean and functional. -

Start and Operate Safely

o Place the rammer on stable ground before starting.

o Start engine per manufacturer guidelines and maintain a firm two-handed grip.

o Do not operate near the edge of trenches, pits, or elevated surfaces. -

Control Vibration Exposure

o Limit continuous use time to prevent hand-arm vibration syndrome (HAVS).

o Take frequent breaks and use vibration-dampening gloves. -

Maintain Safe Operating Posture

o Keep feet and legs clear of the rammer foot during operation.

o Stand with a stable stance to absorb shock and maintain control. -

Fuel Handling and Engine Safety

o Refuel only when the engine is cool and turned off.

o Store fuel in approved containers and away from ignition sources.

o Operate in well-ventilated areas to prevent buildup of toxic fumes. -

Safe Transport and Storage

o Use lifting handles or wheels if available to transport the rammer.

o Store in a dry, secure place away from children and unauthorized users. -

Training and Operation Limits

o Only trained personnel should operate the rammer.

o Follow manufacturer guidelines on soil type, moisture content, and compaction layers. -

Noise and Bystander Safety

o Set up safety barriers in high-traffic or residential areas.

o Ensure bystanders remain at a safe distance during operation.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs