“Pressing Ahead: The Power and Potential of an Oil Expeller” 🌾🥥

In an age where so much of our food is mass-produced, it’s easy to forget that some of the healthiest, freshest products can be made right at home or on-site. Cooking oil is a perfect example. Instead of relying on heavily processed supermarket options, you can create pure, fresh, and nutrient-rich oil with a simple yet powerful tool—the oil expeller.

Whether you’re a small-scale farmer, a health-conscious home cook, or a business owner, an oil expeller offers a level of quality control and versatility that’s hard to beat. It’s not just a machine—it’s a gateway to fresher flavors, better nutrition, and more value from every harvest. 🌻

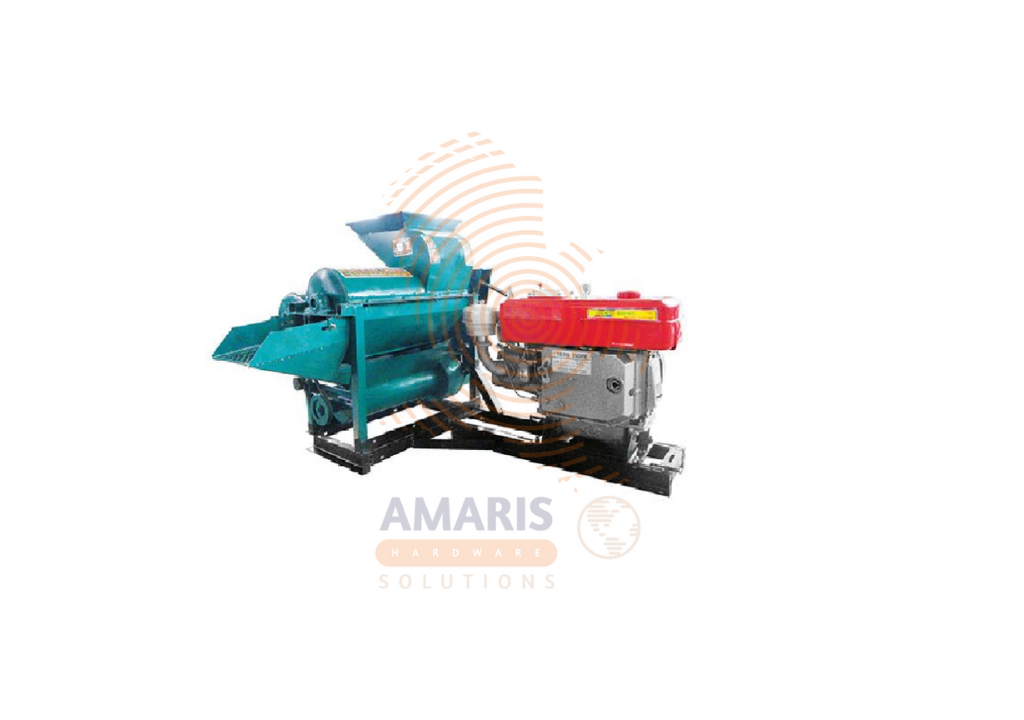

What is an Oil Expeller? 🛠️

An oil expeller—also called an oil press—is a mechanical device used to extract oil from seeds, nuts, and other oil-rich crops. Instead of using harmful chemicals or extreme heat, the expeller uses mechanical pressure to squeeze oil from the raw materials. This process helps retain the natural aroma, flavor, and nutritional content of the oil.

Common raw materials for oil pressing include:

- 🌻 Sunflower seeds

- 🥜 Groundnuts (peanuts)

- 🌴 Palm kernels

- 🥥 Coconuts

- 🌾 Sesame seeds

- 🌱 Soybeans

The end result is oil that’s fresh, flavorful, and free from unnecessary additives.

Why Use an Oil Expeller?

There are several reasons why an oil expeller is such a valuable investment:

- Freshness and Taste – Fresh-pressed oils have a richer, more natural flavor.

- Nutrient Retention – The cold-press method preserves essential vitamins and antioxidants.

- Cost Savings – Producing your own oil can be more economical over time.

- Chemical-Free Production – You know exactly what’s in your oil—no preservatives or artificial agents.

- Multi-Seed Capability – Many models can process different seeds and nuts with ease.

How an Oil Expeller Works ⚙️

The process may sound technical, but it’s surprisingly straightforward:

- Feeding – The seeds are loaded into a hopper.

- Pressing – A rotating screw compresses and crushes them.

- Oil Separation – The oil seeps out through small gaps while the solid residue (known as oil cake) is pushed aside.

- Filtration – If desired, the oil can be filtered to achieve a clearer, more refined finish.

This combination of mechanical force and precision engineering is what makes an oil expeller both efficient and reliable.

Where Can an Oil Expeller Be Used?

- Home Kitchens – Produce small quantities of fresh oil for cooking.

- Commercial Food Businesses – Supply restaurants, markets, or retail shops.

- Cosmetic & Soap Production – Use natural oils for handmade beauty products.

- Animal Feed Production – Turn leftover oil cake into nutrient-rich livestock feed.

- Agricultural Processing – Add value to crops before selling them.

Tips for Getting the Best Results 🌟

- Use Clean, Dry Seeds – Dirt or moisture can reduce efficiency and oil quality.

- Preheat Certain Seeds – Some materials yield more oil when slightly warmed.

- Double Press for Higher Yield – A second pressing can extract additional oil.

- Maintain the Machine Regularly – Lubrication and cleaning extend its lifespan.

- Store Oil Properly – Keep in a cool, dark place to preserve freshness.

Choosing the Right Oil Expeller 🏬

When selecting an oil expeller, look for durability, capacity, and ease of maintenance. At Amaris Hardware Solutions, we provide models designed for both small-scale and industrial oil pressing. Our range includes machines built from robust materials, capable of handling different seeds, and easy to clean and service.

We also ensure our customers have access to spare parts, user guidance, and after-sales support—because the right machine is only as good as the service behind it.

Conclusion 🌱

An oil expeller is more than just a piece of equipment—it’s an investment in healthier living, fresher flavors, and sustainable production. Whether you’re producing sunflower oil for your family or coconut oil for your business, having control over the process means you get a better product every time.

By pressing your own oils, you’re not just making food—you’re making it better.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs