Adjustable Try Square

$6,040.00 Original price was: $6,040.00.$5,540.00Current price is: $5,540.00.

WhatsApp Order

An adjustable try square is a precision measuring tool used in woodworking, metalworking, and other trades to check and mark right angles accurately. Unlike a fixed try square, an adjustable try square allows the user to set the blade at different angles, providing versatility in measuring and marking various angles besides 90 degrees. This adjustable feature enhances the tool’s functionality and makes it a valuable asset for tasks that require precise and customizable angle measurements.

SKU:

AHS63614

Category: Measuring Tools

Description

Adjustable Try Square Uses

- Checking and Marking Right Angles:

- The primary purpose of an adjustable try square is to check and mark right angles accurately. Woodworkers and metalworkers use it to ensure that edges and surfaces are perpendicular to each other.

- Measuring and Marking Angles Other Than 90 Degrees:

- The adjustable feature allows users to set the blade at different angles, making it useful for measuring and marking angles other than 90 degrees. This flexibility is crucial in tasks where non-standard angles are required.

- Setting and Checking Miter Angles:

- Woodworkers often use adjustable try squares to set and check miter angles when cutting bevels or creating joints, such as those used in frame and furniture construction.

- Layout and Marking for Joinery:

- The precision of an adjustable try square is essential for laying out and marking joinery, including mortise and tenon joints, dovetails, and other intricate woodworking connections.

- Ensuring Squareness in Assembly:

- During the assembly of woodworking or metalworking projects, an adjustable try square helps ensure that components are assembled with precise right angles, contributing to the overall accuracy and quality of the finished product.

- Checking Machinery Setup:

- Machinists and metalworkers use adjustable try squares to check the alignment and setup of machinery. This ensures that cutting tools and workpieces are positioned correctly for accurate machining operations.

- Quality Control in Manufacturing:

- In manufacturing settings, adjustable try squares play a role in quality control by verifying the accuracy of components and ensuring that they meet specified geometric requirements.

- Carpentry and Framing:

- Carpenters use adjustable try squares for framing and layout work. Ensuring squareness is crucial in tasks such as framing walls, installing doors and windows, and constructing various wooden structures.

- Marking and Layout in DIY Projects:

- DIY enthusiasts and hobbyists find adjustable try squares handy for accurate marking and layout in a variety of projects, including home improvement tasks and crafting.

Reviews (0)

Be the first to review “Adjustable Try Square” Cancel reply

Related products

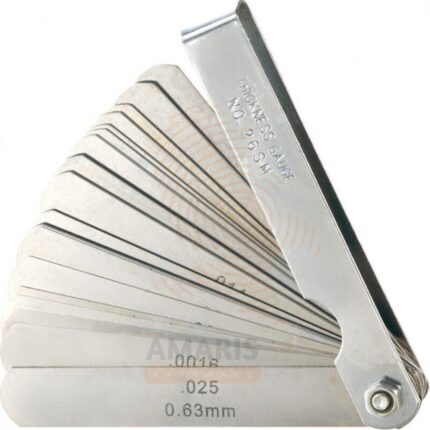

26 pcs Combination Feeler Gauge Set

A 26pcs Combination Feeler Gauge Set is a precision measuring tool consisting of 26 individual blades or leaves, each with a specific thickness. These blades are designed to measure the clearance or gap between two objects, commonly used in settings such as automotive maintenance, machining, and other mechanical applications. The blades are typically made of durable materials such as stainless steel and are marked with their corresponding thickness values in either metric or imperial units. Users can select the appropriate blade from the set to check and adjust the tolerances between components, ensuring proper fit and functionality in various mechanical systems.

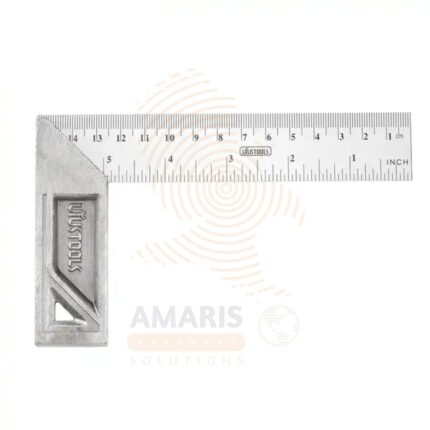

Combination Try Square

A Combination Try Square is a versatile measuring tool used in woodworking and metalworking to ensure the accuracy of right angles and measure or check the squareness of edges and surfaces. It typically consists of a ruler or blade attached to a handle at a 90-degree angle, allowing for both linear measurements and the verification of perpendicular angles. The "combination" aspect often refers to additional features, such as a spirit level or an adjustable head, which enhances its functionality for various precision tasks.

Heavy duty Try Square

A Try Square with Powder Metallurgy Base is a high-quality, durable measuring tool with a precision- machined blade and a base crafted through powder metallurgy techniques. It is designed for accurate right-angle measurements in woodworking and metalworking, offering versatility and reliability in hardware applications.

Heavy-duty Try Square

A Heavy-duty try square with Powder Metallurgy Base is a high-quality, durable measuring tool with a precision- machined blade and a base crafted through powder metallurgy techniques. It is designed for accurate right-angle measurements in woodworking and metalworking, offering versatility and reliability in hardware applications.

Level Tripod

A level tripod refers to a three-legged support structure or stand that is designed and constructed to ensure stability and a flat, horizontal orientation when placed on uneven surfaces. The term "level" in this context implies that the tripod has mechanisms or adjustments that allow users to align it precisely, ensuring that the platform or mount on top of the tripod remains parallel to the ground. This feature is crucial for various applications, such as photography, surveying, and other activities where stability and accurate leveling are essential for optimal results.

Protractor

A protractor is a measuring instrument used in geometry and mathematics to quantify angles. It typically consists of a flat, semicircular or circular tool made of transparent or opaque material, marked with degree measurements from 0 to 180 or 0 to 360. The center of the protractor usually has a pivot point, allowing it to be placed at the vertex of an angle for accurate measurement. Users align the protractor's baseline with one side of the angle and read the degree value where the other side intersects the protractor scale to determine the angle's measurement. Protractors come in various designs, including simple plastic versions for basic measurements and more advanced models with additional features for specific applications.

Tape Measure(Steel Tape Rule)

A tape measure is a flexible ruler-like tool used for measuring distances or dimensions. Typically made of a strip of metal, fiberglass, or cloth, it features markings in standardized units (such as inches or centimeters) along its length. One end usually has a tab or hook that can be hooked onto an object for precise measurements, while the other end retracts into a compact housing for convenient storage. Tape measures are widely used in various fields, including construction, carpentry, sewing, and other applications where accurate measurements of length or distance are essential.

Torpedo Level – Magnetic

A magnetic torpedo level is a specialized measuring tool used in construction and carpentry to ensure that surfaces or objects are level or plumb. It typically consists of a rectangular or torpedo-shaped body filled with liquid, with a bubble inside. The level incorporates one or more magnets to attach securely to metal surfaces, aiding in hands-free operation. The user aligns the level by adjusting the position of the object or surface until the bubble is centered between two markers, indicating that it is level or plumb. The magnetic feature enhances stability and ease of use, especially when working on metal structures or surfaces.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.