Block Macking Machine

WhatsApp Order

A Block Making Machine is a specialized construction equipment designed to produce high-quality concrete blocks, bricks, and pavers used in building and infrastructure projects. It automates the process of mixing, molding, compacting, and curing concrete materials into consistent, uniform blocks of various sizes and shapes. These machines can be manual, semi-automatic, or fully automatic, depending on their level of automation and production capacity. They are widely used in commercial, industrial, and residential construction projects for producing large volumes of concrete masonry units efficiently.

Description

USES

- Manufacturing concrete blocks for walls, pavements, and fences

- Producing hollow blocks, solid blocks, paving stones, and curbstones

- Creating interlocking blocks for retaining walls and roadways

- Mass production of blocks for commercial and residential construction

- On-site block production to reduce material transportation costs

- Fabricating colored or decorative concrete blocks for aesthetic finishes

- Supporting low-cost housing projects through localized production

- Making heat-resistant and soundproof blocks for specialized structures

- Creating foundation blocks for civil engineering applications

- Producing blocks for boundary walls, partitions, and utility buildings

- Used in municipal projects for sidewalks and urban development

- Creating ventilated blocks for enhanced airflow in buildings

- Suitable for rural or remote construction sites with limited access to supply chains

Used in eco-friendly building solutions by incorporating recycled materials

SAFETY HANDLING PRECAUTIONS

- Wear Personal Protective Equipment (PPE)

- Use safety goggles to protect eyes from dust and debris

- Wear gloves to prevent hand injuries during material handling

- Use ear protection if working with high-noise machines

- Wear safety boots and durable clothing on-site

- Read and Follow the User Manual

- Familiarize yourself with machine controls, emergency stops, and operational guidelines

- Follow manufacturer recommendations for setup, maintenance, and troubleshooting

- Check Equipment Before Use

- Inspect hydraulic systems, electrical components, and molds for wear or damage

- Ensure all safety guards and sensors are functional

- Use Proper Lifting Techniques

- Handle raw materials and finished blocks using correct posture or mechanical aids

- Keep Work Area Clean

- Remove debris and concrete spills to prevent slips and trips

- Maintain clear access around the machine for safe operation

- Avoid Manual Contact with Moving Parts

- Never reach into the machine while it is running

- Use tools or sticks to dislodge material jams

- Operate with Trained Personnel Only

- Ensure operators are trained in machine operation and emergency procedures

- Perform Routine Maintenance

- Regularly lubricate mechanical parts and clean molds

- Replace worn parts to prevent accidents or malfunctions

- Avoid Overloading the Machine

- Do not exceed the capacity specified by the manufacturer to prevent breakdowns or injury

- Use in a Well-Ventilated Area

- Ensure adequate airflow if using chemicals or additives with the concrete mix

Related products

Box Beam Spirit Level Pro – Magnetic

PRODUCT DESCRIPTION

A Box Beam Spirit Level Pro with Magnetic Base is a precision hand tool used for measuring the levelness and plumbness of surfaces. Its rigid box-shaped aluminum body provides durability and stability during use. The tool contains liquid-filled vials with air bubbles to indicate horizontal, vertical, and 45-degree angles. The magnetic base allows for secure attachment to metal surfaces, enabling hands-free operation. This level is essential in construction, carpentry, metalworking, and any tasks requiring accurate surface alignment.

Concrete Mixer

PRODUCT DESCRIPTION

A concrete mixer is a vital construction machine designed for perfectly blending cement, aggregates (such as sand and gravel), and water into high-quality concrete. It features a rotating drum on a sturdy frame—either powered by electricity, gas, or manually—that keeps the mixture in a homogenous, workable state to ensure consistency with each batch. Concrete mixers mitigate manual labor, speed up work, and guarantee a uniform concrete mix suitable for foundations, slabs, pillars, beams, driveways, and more. Variants include portable barrel mixers for small projects and large-capacity tilt or drum mixers for commercial use, ensuring proper mixing, reducing waste, and improving overall construction efficiency.

Fiberglass Open Reel Long Tape Rule

PRODUCT DESCRIPTION

A Fiberglass Open Reel Long Tape is a measuring tool designed for accurately determining distances in various applications, such as construction, surveying, and landscaping. It typically consists of a durable, flexible fiberglass tape housed on an open reel. The fiberglass material provides strength and resistance to stretching, ensuring precise measurements over extended lengths. The open reel design allows for easy deployment and retraction of the tape, facilitating efficient use in outdoor and large-scale measurement scenarios. These tapes often feature clear and legible markings, making them suitable for both personal and professional use in situations where accurate and reliable distance measurements are essential.

Flat Webbing Slings

A flat webbing sling is a flexible and durable lifting or towing device made from a flat strip of synthetic material, typically polyester, nylon, or polypropylene. These slings are designed for various material handling applications, such as lifting and securing loads in construction, manufacturing, and transportation industries. The flat design allows for a wide surface area, distributing the load evenly and reducing the risk of damage to the load. Flat webbing slings often feature reinforced loops at each end for attachment to lifting equipment, providing a versatile and reliable solution for lifting and moving heavy objects.

Professional Manual Tile Cutter

A professional manual tile cutter is a specialized tool designed for accurately and cleanly cutting ceramic or porcelain tiles during the installation process. It typically consists of a sturdy base, a scoring wheel or blade, and a handle. The user places the tile on the cutter, scores a line on the surface of the tile using the cutting wheel, and then applies pressure to break the tile along the scored line. Professional manual tile cutters are known for their precision, efficiency, and the ability to produce clean and straight cuts, making them essential for professional tile installers and DIY enthusiasts working on tiling projects.

Putty Knife – Bi Material Handle

A putty knife with a bi-material handle refers to a tool used for scraping and spreading putty, filler, or other materials, featuring a handle made from two different materials. The bi-material handle typically incorporates a combination of materials such as rubber, plastic, or another soft and comfortable grip material for ergonomic handling, along with a more rigid material for durability and structural support. This design aims to provide users with a comfortable grip while ensuring the tool remains sturdy and effective for its intended purposes.

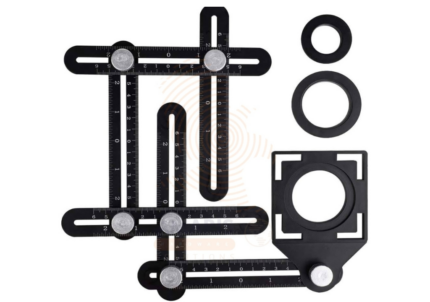

Six Sided Angle Measuring Tool

A Six Sided Angle Measuring Tool, commonly known as a hexagonal protractor, is a geometric instrument with six equal sides and six internal angles, each measuring 120 degrees. This tool is specifically designed to facilitate the measurement and drawing of angles in various applications, such as geometry and engineering. The angles are typically marked or calibrated along the edges, allowing users to accurately determine and replicate specific angular measurements during drafting or other precision tasks.

Tile Grout Float

A tile grout float is a tool used in the process of installing ceramic or stone tiles. It typically consists of a flat, rectangular or square-shaped rubber or foam pad attached to a handle. The purpose of a tile grout float is to apply and spread grout into the joints between tiles. The flat surface of the float helps ensure an even distribution of grout and allows for effective filling of spaces between tiles. After the grout is applied, excess grout can be wiped away with the edge of the float. Overall, a tile grout float is an essential tool for achieving a clean and professional finish when grouting tile installations.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors and Accessories: Belts and Rollers

Conveyors and Accessories: Belts and Rollers