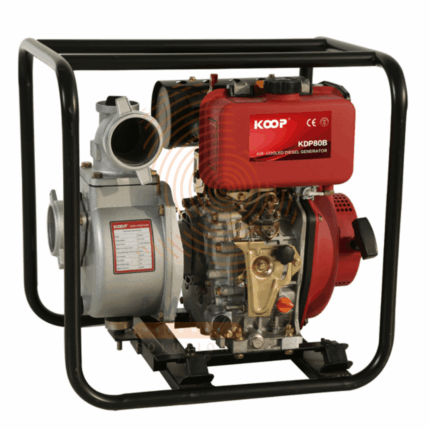

Water Pump

The Water Pump is a high-performance, multi-purpose device engineered to efficiently move water from one location to another across residential, agricultural, industrial, and commercial settings. Built with a powerful motor and durable components, it ensures consistent water flow for a wide range of applications—from household water supply and irrigation to drainage and construction site dewatering. Designed for reliability, efficiency, and long service life, this pump is ideal for tasks that demand fast, dependable water transfer, making it an essential tool for homeowners, farmers, contractors, and facility managers alike.

Water Pump Uses

- Domestic Water Supply and Pressure Boosting:

Water pumps are commonly used to draw water from wells, tanks, or municipal lines to ensure steady water pressure and supply for showers, taps, and appliances in homes. - Irrigation for Lawns, Gardens, and Farmlands:

Perfect for delivering water to plants and crops, water pumps power sprinkler systems, drip irrigation, and surface watering to maintain healthy landscapes and agricultural yields. - Construction Site Dewatering and Flood Control:

Water pumps remove standing water from excavations, basements, and foundations during construction or after heavy rainfall, keeping sites safe and dry. - Filling and Draining Swimming Pools, Ponds, and Tanks:

These pumps quickly fill or empty large bodies of water, making them ideal for seasonal maintenance, cleaning, or water replacement in recreational and decorative features. - Water Transfer Between Storage Containers:

Used to move water between cisterns, barrels, and storage tanks, particularly in rainwater harvesting, off-grid systems, or during emergency situations. - Livestock Watering Systems and Barns:

Farmers use water pumps to supply fresh water to troughs and automated livestock watering systems, ensuring hydration and hygiene for animals. - Industrial Cooling and Process Water Circulation:

In factories and plants, pumps circulate water for machinery cooling, production processes, or cleaning systems to maintain operational efficiency. - Marine and RV Freshwater Systems:

Small water pumps are installed in boats and recreational vehicles to deliver running water to sinks, showers, and toilets when off the grid. - Firefighting and Emergency Water Supply:

High-capacity water pumps are used to draw water from lakes, ponds, or tanks for firefighting or emergency water delivery in rural areas. - Pressure Washing and Cleaning Systems:

Some water pumps serve as the power source for pressure washers, helping clean vehicles, buildings, sidewalks, and equipment with high-pressure water jets.

Safety Precautions

- Check Power Supply – Ensure proper voltage and grounding

- Inspect Hoses & Fittings – No cracks, leaks, or loose connections

- Prime the Pump – Fill with water before starting (if non-self-priming)

- Disconnect Power – Before servicing or storage

Storage Procedures

- Drain Completely – Remove all water to prevent freezing/corrosion

- Clean Impeller & Housing – Remove debris and mineral buildup

- Lubricate Seals – Apply silicone grease to prevent drying

- Store in Dry Place – Avoid moisture and extreme temperatures

Critical Warnings

- NEVER run the pump dry – damages seals and impeller

- NEVER operate with clogged intake

- NEVER store with water inside

Peripheral Pump

Voltage:220-240V~50Hz

Rated power:370W(0.5HP)

Max.head:35m

Max.flow:35L/min

Max.suction:8m

Pipe diameter:1"x1"

Copper wire motor

Stainless steel welding shaft: 304+45#

Electrophoresis pump body

Brass impeller

0.3m length cable

Packed by color box

Available with different specifications:

Including:

Rated power:750W(1HP)

Max.head:52m

Max.flow:50L/min

Max.suction:8m

Packed by carton box

Related products

Clean Water Submersible Pump

Clean Water Submersible Pump

- Clean Water: Indicates that the pump is designed for use with water that is relatively free from impurities or debris. It is suitable for applications where the water being pumped does not contain significant contaminants.

- Submersible: Describes the pump's design, which allows it to be fully submerged in the water it is pumping. Submersible pumps are often used in wells, boreholes, or other water sources where the pump needs to operate beneath the water surface.

- 0.75 HP (Horsepower): Specifies the power rating of the pump. In this case, the pump has a power output of 0.75 horsepower, indicating its capacity to move a certain volume of water per unit of time.

- 25 M: This likely refers to the maximum pumping or discharge head, which is the vertical distance the pump can lift water. In this case, the pump can effectively lift water to a height of 25 meters.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.