“Fibre Strengthened Resin Cutting Wheel” has been added to your cart. View cart

Cutting Wheel of Tile Cutter

$7,180.00 Original price was: $7,180.00.$6,680.00Current price is: $6,680.00.

Cylinder Brush(outer wall)

$8,080.00 Original price was: $8,080.00.$7,580.00Current price is: $7,580.00.

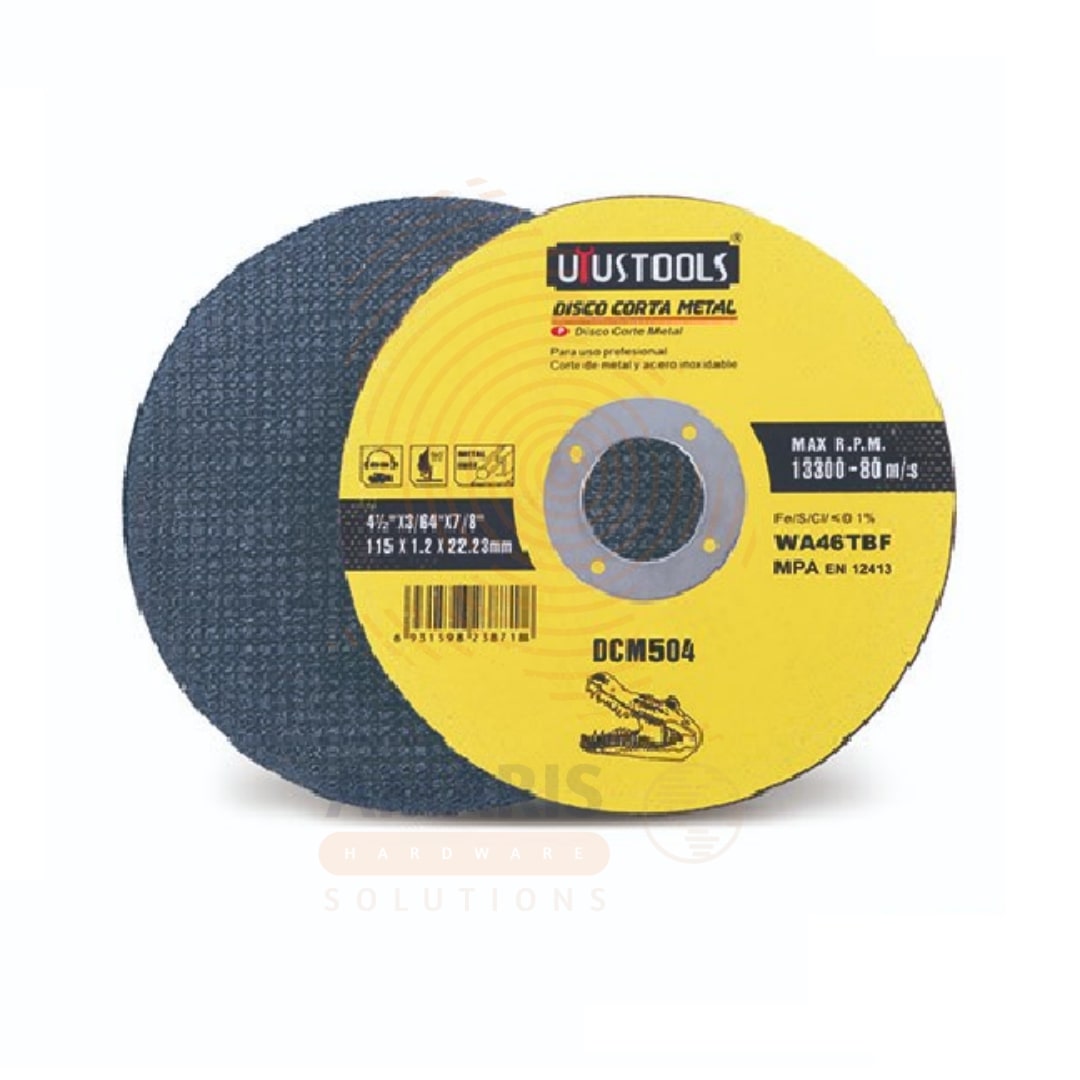

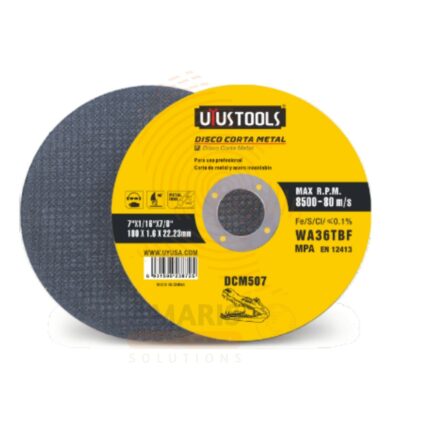

Cutting Wheel Thin

$3,460.00 Original price was: $3,460.00.$2,960.00Current price is: $2,960.00.

WhatsApp Order

A cutting wheel, specifically a thin cutting wheel, is a specialized abrasive tool designed for precision cutting in various materials such as metal, plastic, or stone. It typically consists of a thin, flat, circular disc made of abrasive material bonded with resin or other substances. The thin profile of the cutting wheel allows for narrow cuts and reduces material wastage. These wheels are commonly used with angle grinders or rotary tools and are employed in applications ranging from metal fabrication and construction to DIY projects.

SKU:

AHS63917

Category: Cutting Tools

Description

Cutting Wheel Thin Uses

- Metal Cutting:

- Thin cutting wheels are widely used for cutting metal sheets, pipes, and rods in industries such as metal fabrication, construction, and manufacturing.

- Construction and Renovation:

- These cutting wheels are essential for tasks like cutting rebar, steel studs, or metal framing in construction projects.

- Automotive Repairs:

- In automotive repair and customization, thin cutting wheels are used for cutting and modifying metal components, such as exhaust pipes or body panels.

- DIY Projects:

- Thin cutting wheels are popular among DIY enthusiasts for tasks like cutting metal pipes, bolts, or other materials in home improvement and crafting projects.

- Plastic Cutting:

- They are also suitable for cutting various types of plastics, providing a clean and precise cut in applications like plumbing or customizing plastic materials.

- Tile Cutting:

- Thin cutting wheels are employed for cutting ceramic or stone tiles in construction and tiling projects.

- Precision Cuts:

- Due to their thin profile, these wheels are ideal for making precise and narrow cuts, allowing for intricate and detailed work in various materials.

- Maintenance and Repairs:

- In industrial maintenance and repair work, thin cutting wheels are used for tasks such as removing welds, cutting worn-out parts, or modifying metal structures.

- Sheet Metal Fabrication:

- Thin cutting wheels play a crucial role in sheet metal fabrication processes, enabling the precise cutting of thin metal sheets for various components.

- Metal Sculpting:

- Artists and metal sculptors use thin cutting wheels for shaping and cutting metal pieces in the creation of sculptures and artwork.

Reviews (0)

Be the first to review “Cutting Wheel Thin” Cancel reply

Related products

3pcs Step Drill Set — Metric

A three-piece step drill set is a specialized tool kit designed for drilling holes with varying diameters in materials such as metal, plastic, or wood. Each drill in the set has multiple steps or graduated levels with increasing diameters. This enables users to drill different-sized holes using a single tool by gradually stepping up the size in predetermined increments. Step drill sets are commonly used in various applications, including electrical work, metal fabrication, and general construction, where precise hole sizes are required.

6 in 1 Cordless Multi tool

A 6-in-1 cordless multi tool with a 20V power rating typically refers to a versatile handheld tool that combines six different functions or attachments, all powered by a 20-volt battery. The "6-in-1" designation implies that the tool can perform six distinct tasks or has six interchangeable attachments, providing users with flexibility and convenience for various applications. Common features of such multi-tools may include functions like drilling, cutting, sanding, and more, making it a comprehensive solution for a range of DIY or professional tasks. The 20V power rating indicates the voltage of the rechargeable battery, which influences the tool's performance and runtime. Higher voltage generally translates to more power and longer usage time between charges. Overall, a 6-in-1 cordless multi-tool is designed to streamline work and enhance efficiency by consolidating multiple tools into a single, portable device.

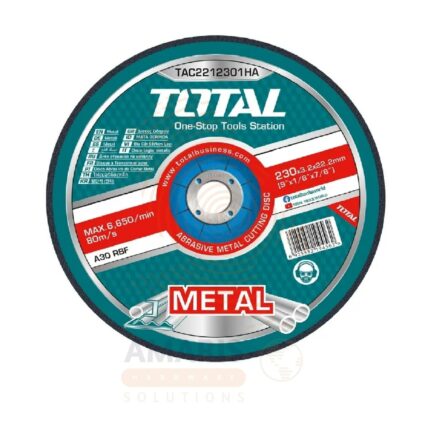

Abrasive Metal Cutting Disc

An abrasive metal cutting disc is a specialized tool used in metalworking and construction applications. It is a circular, flat disc typically composed of abrasive materials such as aluminum oxide or silicon carbide, bonded together with resin or other materials. The disk is designed to efficiently cut through various types of metal, including steel and aluminum, by abrasive action.

These cutting disks are mounted on power tools such as angle grinders or chop saws, where the rotation of the disk creates friction against the metal surface, generating heat and wearing away the material. The abrasive particles on the disk act like tiny cutting edges, slicing through the metal and producing clean and precise cuts. Abrasive metal cutting disks are widely used for tasks such as cutting pipes, rods, sheet metal, and other metalwork applications where a high degree of precision and efficiency is required. Proper safety precautions, including the use of personal protective equipment, should be followed when using abrasive metal cutting disks to prevent accidents and injuries.

Bi-Metal Hole Saw

A bi-metal hole saw is a specialized cutting tool used in woodworking, metalworking, and other industries to create holes in various materials. It consists of a cylindrical saw blade with teeth around its edge, and it is called "bi-metal" because it is constructed using two different types of materials.

Typically, the body of the hole saw is made from a softer and more flexible material, such as spring steel, while the cutting edges are composed of a harder and more durable material, often high-speed steel (HSS) or a similar alloy. This combination of materials enhances the saw's overall performance by providing the flexibility of the body and the cutting efficiency of the harder edges.

Bi-metal hole saws are known for their versatility and ability to cut through a wide range of materials, including wood, plastic, drywall, and various metals. They are commonly used in construction, plumbing, electrical work, and other trades where creating precise and clean holes is essential. The two-material construction allows the hole saw to withstand the stresses of cutting different materials while maintaining sharpness and durability.

Diamond Cutting Blade (Dry) – Hot Press

A diamond cutting blade (dry), hot press is a specialized tool used in construction and fabrication processes for cutting hard materials such as stone, concrete, or ceramics. This type of blade is characterized by its use of diamond crystals embedded in a metal matrix on the cutting edge. The term "dry" indicates that the blade is designed to operate without the need for water or other cooling agents during the cutting process. The "hot press" method refers to the manufacturing technique where the diamond particles are bonded to the blade through a high-temperature and high-pressure process, ensuring a durable and efficient cutting tool.

Fibre Strengthened Resin Cutting Wheel

A fiber-strengthened resin cutting wheel refers to a cutting tool designed for various machining applications, particularly in the context of metalworking or construction. This type of cutting wheel is composed of a resin matrix, which serves as a binding material, reinforced with fibers for added strength and durability. The fibers are typically made of materials such as fiberglass or other composite materials.

The combination of resin and fibers enhances the cutting wheel's structural integrity, making it more resistant to breakage and providing improved performance during cutting operations. The reinforced design allows the wheel to withstand higher levels of mechanical stress and heat generated during cutting processes. Fiber-strengthened resin cutting wheels are commonly used in applications like cutting metal, steel, or other hard materials, where precision and durability are crucial.

Turbo Diamond Disc

A turbo diamond disc, often referred to as a turbo diamond blade or turbo diamond wheel, is a cutting tool used in various construction and fabrication applications. It is designed for cutting through hard materials such as concrete, stone, brick, and other masonry surfaces. The "turbo" in its name refers to the segmented rim of the blade, which typically features a pattern of ridges or gullets that aid in cooling and clearing debris during the cutting process.

The blade is embedded with industrial-grade diamonds on its cutting edge, allowing it to efficiently grind and slice through tough materials. The use of diamonds enhances the cutting performance and durability of the disk. Turbo diamond disks are commonly employed in tasks such as concrete cutting, tile installation, and other construction projects where precision and efficiency are crucial.

Wall chaser

The Wall Chaser is designed to cut clean, straight grooves in concrete, brick, and plaster walls for installing electrical wiring, plumbing pipes, and HVAC lines. Ideal for professionals and DIYers, it enables efficient, dust-controlled cutting, making wall installations neater and faster. Perfect for renovation, new construction, and smart home setups.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.