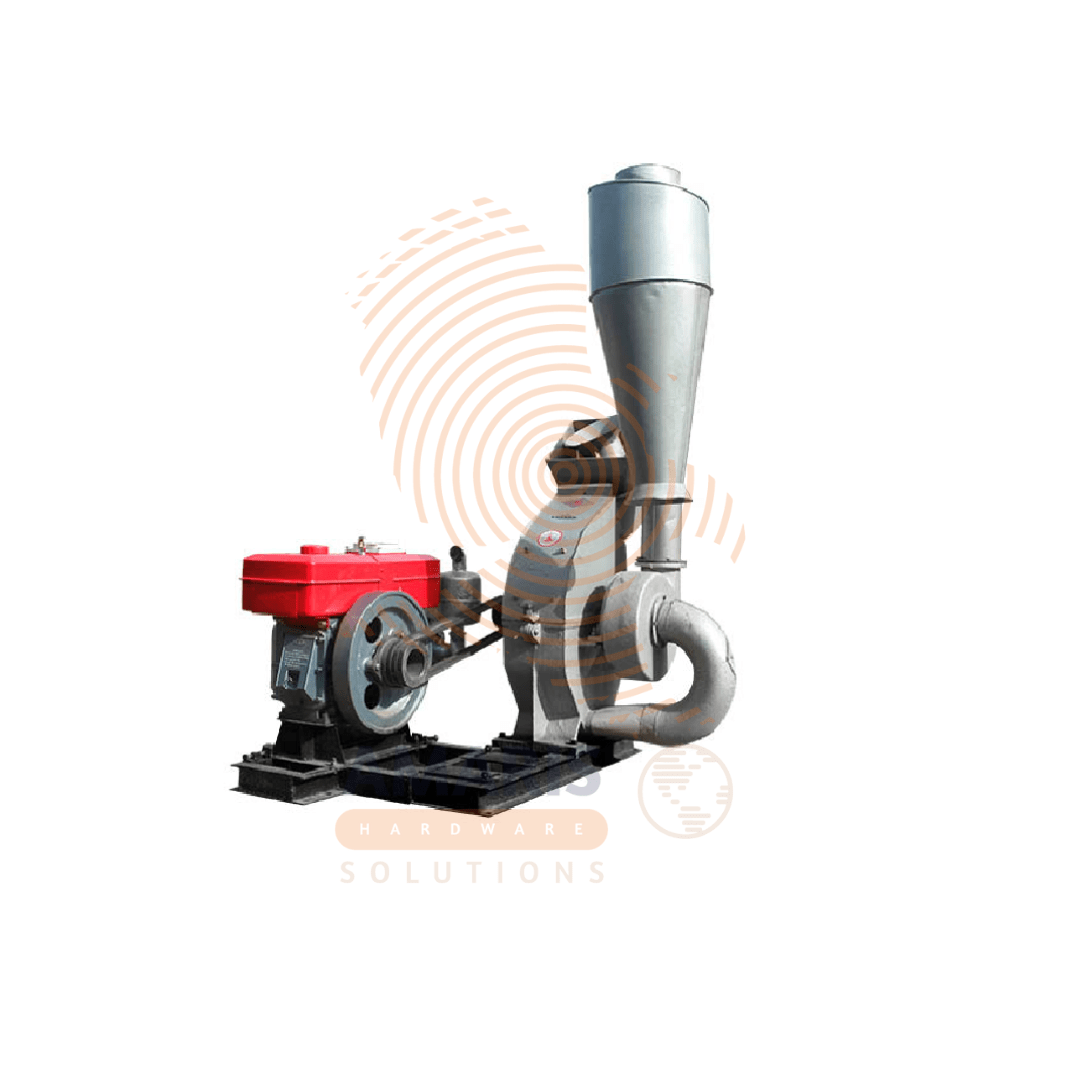

Hammer Mill

WhatsApp Order

A hammer mill is a machine used in various industries to shred or crush materials into smaller pieces by repeatedly pounding them with rapidly rotating hammers. It is commonly used in agricultural, mining, and waste management applications to process raw materials or waste into smaller, more manageable forms for further processing or disposal.

SKU:

AHS52941

Category: Agricultural Processing Machinery

Description

Hammer Mill Uses

- Grinding Grains: Hammer mills are frequently used in agricultural settings to grind grains such as corn, wheat, barley, and oats into smaller particles for animal feed production.

- Size Reduction: They are utilized in various manufacturing processes to reduce the size of raw materials, such as wood chips, sawdust, or other biomass, for purposes like pelletizing, briquetting, or as raw material for biofuel production.

- Recycling Operations: Hammer mills are integral in recycling operations, particularly in the processing of scrap metal, electronic waste, and other recyclables. They help in breaking down materials into smaller pieces for sorting, separation, and further processing.

- Herb and Spice Grinding: Hammer mills are employed in food processing industries for grinding herbs, spices, and other food ingredients into fine powders or granules for use in culinary applications or as ingredients in food products.

- Mining and Mineral Processing: Hammer mills are used in the mining industry for crushing and grinding various minerals and ores to liberate valuable metals or minerals from the surrounding rock.

- Size Reduction in Pharmaceutical Industry: In pharmaceutical manufacturing, hammer mills are used for size reduction of pharmaceutical ingredients, granules, and powders, aiding in drug formulation processes.

- Chemical Industry: Hammer mills are employed in chemical processing industries for grinding, pulverizing, or breaking down chemical compounds into smaller particles for further processing or as intermediates in chemical reactions.

- Fertilizer Production: They are used in the production of fertilizers to grind and process raw materials such as phosphate rock, urea, or other ingredients into a finer consistency suitable for blending and pelletizing.

- Rendering Industry: Hammer mills are utilized in rendering plants to process animal by-products, such as bones, feathers, and offal, into meals or powders for use in various applications, including animal feed and industrial processes.

- Construction and Demolition Waste Recycling: In the construction and demolition waste recycling sector, hammer mills are employed to shred and pulverize construction debris and demolition waste materials into smaller particles for reuse or disposal.

Reviews (0)

Be the first to review “Hammer Mill” Cancel reply

Related products

Feed Mixer

A feed mixer is a machine designed to combine various ingredients used in animal feed production, such as grains, supplements, and additives, to create a homogenous mixture. It ensures uniform distribution of nutrients throughout the feed, promoting balanced nutrition for livestock. These mixers come in various sizes and configurations, ranging from small-scale units suitable for hobby farms to large industrial systems for commercial operations.

Hay Baler

A hay baler is a piece of agricultural machinery designed to compress cut hay or straw into compact, manageable bales for storage, transportation, and livestock feed. These machines typically gather loose hay, compress it into a tight bundle, and then tie it with twine or wire to maintain its shape. Hay balers come in various sizes and configurations, from small, manually operated units to large, tractor-pulled or self-propelled models capable of handling significant volumes of hay.

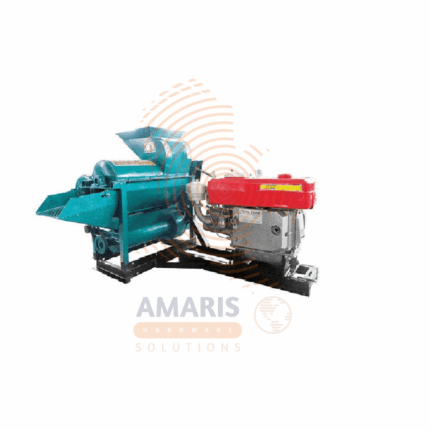

Maize Sheller

A maize sheller is a mechanical device designed to remove the kernels of maize (also known as corn) from the cob efficiently. It typically consists of a cylindrical chamber with ridges or protrusions inside that help to separate the kernels from the cob as it passes through. The sheller may be operated manually, using hand-cranking or foot-pedaling, or it may be powered by electricity or an internal combustion engine for larger-scale operations. The primary function of a maize sheller is to streamline the process of maize harvesting by automating the task of separating kernels from the cob, thus increasing efficiency and productivity in agricultural settings.

Milking Machine

A milking machine is a mechanical device designed to extract milk from the udders of dairy animals such as cows, goats, and sheep. It typically consists of a vacuum pump, pulsator, vacuum lines, and milking units which attach to the animal's teats. The machine mimics the sucking action of a nursing calf or kid, gently massaging the udder to stimulate milk let-down while efficiently collecting the milk into a storage container.

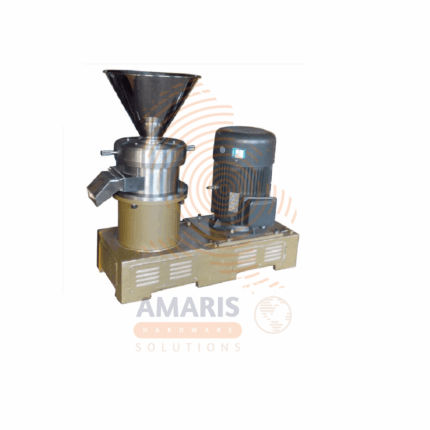

Pellet Machine

A pellet machine, also known as a pellet mill or pelletizer, is a mechanical device designed to compress various biomass materials into uniform cylindrical pellets. These pellets are typically used as a renewable fuel source for heating or cooking purposes, or as feed for animals in the agricultural industry. The machine applies pressure and heat to the raw materials, forcing them through a die with small holes to form compacted pellets of consistent size and density.

Planter

A planter is a container, typically made of various materials such as clay, ceramic, plastic, or wood, designed to hold soil or growing medium for the purpose of cultivating plants. It is commonly used for gardening and landscaping, allowing individuals to grow flowers, herbs, vegetables, or other vegetation in a controlled environment, often placed indoors or outdoors depending on the needs of the plants and the preferences of the gardener. Additionally, planters can vary in size, shape, and design, offering versatility and aesthetic appeal to enhance the beauty of gardens, patios, balconies, and indoor spaces.

Rice Grader

A Rice grader is a machine used in rice processing facilities to sort and classify rice grains according to their size, shape, and quality. This machine employs various mechanisms such as sieves, screens, and air blowers to separate broken grains, foreign particles, and different grades of rice based on predetermined criteria. The primary purpose of a Rice grader is to ensure uniformity and consistency in the quality of rice products, meeting market standards and customer preferences.

Rice Mill

A rice mill is an industrial facility designed for the processing of rice grains to produce various products such as refined rice for consumption, rice flour, rice bran, and other by-products. It involves a series of steps including cleaning, husking, polishing, sorting, and packaging, aimed at transforming raw rice into marketable products ready for distribution and consumption.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.