Oil Expeller

$ 319.23 Original price was: $ 319.23.$ 303.27Current price is: $ 303.27.

Paint Brush Plastic Handle

$ 14.19 Original price was: $ 14.19.$ 13.48Current price is: $ 13.48.

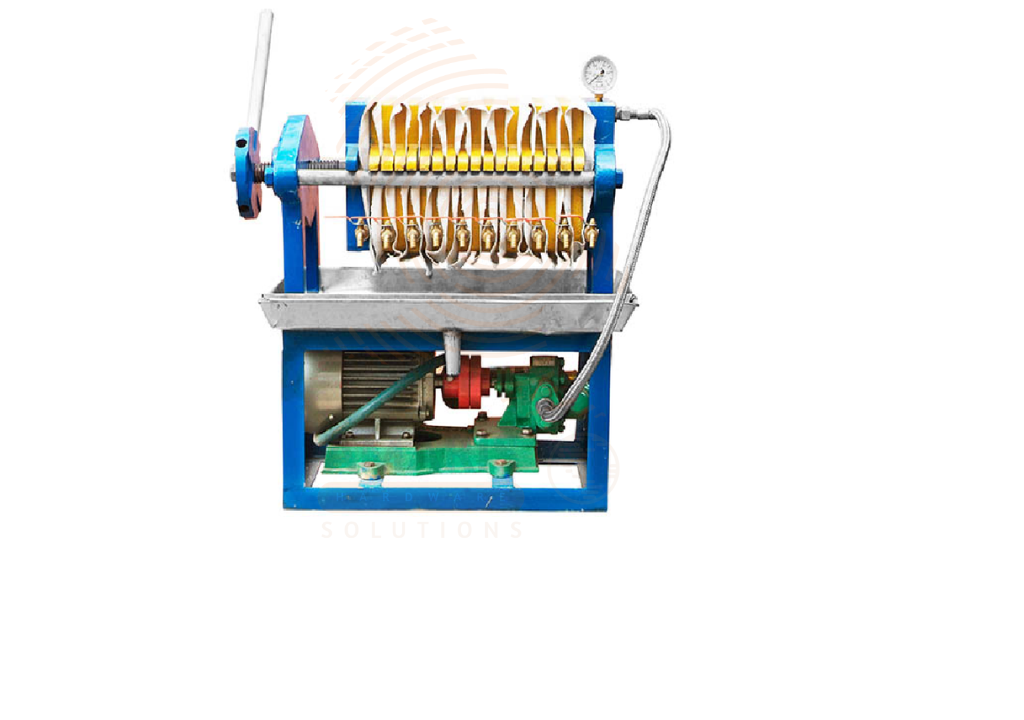

Oil Filter

$ 88.46 Original price was: $ 88.46.$ 83.04Current price is: $ 83.04.

WhatsApp Order

An Oil Filter is a critical component used in engines, hydraulic systems, and machinery to remove contaminants from lubricating oil, transmission oil, engine oil, or hydraulic fluid. It ensures clean oil circulates through the system, protecting internal components from wear and maintaining efficient performance. Oil filters are commonly found in vehicles, generators, industrial equipment, and agricultural machinery. By trapping dirt, metal particles, and sludge, the oil filter prolongs engine life and reduces maintenance needs.

Description

Table of Contents

ToggleOil Filter

Uses

-

Engine Protection

o Filters engine oil in cars, trucks, motorcycles, and heavy-duty machinery to prevent internal damage.

o Keeps oil clean for optimal lubrication and cooling. -

Hydraulic System Maintenance

o Removes contaminants in hydraulic oils used in forklifts, cranes, and other heavy equipment.

o Preserves hydraulic pump and valve performance. -

Generator Maintenance

o Used in diesel and gasoline-powered generators to ensure uninterrupted, clean lubrication.

o Reduces risk of engine failure during continuous operation. -

Industrial Equipment Lubrication

o Filters circulating oil in compressors, gearboxes, and industrial machines.

o Ensures long-term reliability of critical machinery. -

Agricultural Equipment Efficiency

o Maintains oil cleanliness in tractors, harvesters, and other farm equipment.

o Minimizes downtime and mechanical breakdowns. -

Transmission System Filtering

o Filters transmission fluid in automatic and manual systems.

o Improves shifting performance and transmission lifespan. -

Oil Refinement in Processing Units

o In some setups, filters process oils before recirculation or reuse.

o Enhances oil recycling efficiency. -

Marine and Aviation Engines

o Ensures clean lubrication in high-demand environments.

o Maintains reliability in critical operations. -

Heavy-Duty Off-Road Equipment

o Ensures system cleanliness in excavators, loaders, and mining vehicles.

o Reduces maintenance costs and operational hazards.

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Wear Protective Gear

o Use gloves to prevent skin contact with hot or dirty oil.

o Wear safety glasses to protect eyes from splashes during removal or installation. -

Depressurize System Before Servicing

o Shut off engine or machinery and allow oil pressure to drop before removing the filter.

o Avoid hot surfaces to prevent burns. -

Use Correct Filter Type

o Ensure compatibility with specific machinery or engine model.

o Using the wrong filter can lead to leaks or failure. -

Inspect Old Filter

o Check removed filter for metal debris or sludge that may indicate internal wear.

o Properly dispose of used oil and filters in accordance with environmental regulations. -

Ensure Tight Installation

o Lubricate new filter gasket before installation.

o Hand-tighten and avoid over-tightening to prevent seal damage. -

Check for Leaks Post-Installation

o Run the engine briefly and inspect for oil leaks around the filter seal.

o Re-tighten or replace if necessary. -

Avoid Oil Spills

o Use oil pans and absorbents when removing old filters.

o Clean spills immediately to prevent slips. -

Routine Maintenance

o Replace filters at recommended intervals to prevent clogging and oil starvation.

o Keep maintenance records for equipment performance tracking. -

Environmental Handling

o Store used filters in sealed containers.

o Recycle according to local hazardous waste disposal guidelines.

Related products

Big Battery Pro

A " Big Battery Pro" typically refers to a rechargeable lithium-ion battery with a nominal voltage of 20 volts. The nominal voltage represents the average voltage output over the majority of the battery's discharge cycle. It's important to note that the actual voltage during use may fluctuate within a specified range.

These batteries are commonly used to power various devices, including power tools, garden equipment, and other portable electronic devices. The "20V" designation is a standardized measure indicating the electrical potential of the battery, providing a general indication of its power output.

Keep in mind that when considering a 20V battery, it's essential to verify compatibility with the specific device or tool it is intended for. Additionally, different manufacturers may have variations in the actual voltage, capacity, and features of their 20V battery products. Checking the product documentation or contacting the manufacturer for detailed specifications is recommended for accurate information.

Coil Spring Compressor

A coil spring compressor is a tool designed to safely compress and temporarily shrink coil springs for various automotive and mechanical applications. It consists of two threaded rods with hooks or clamps on each end and a central mechanism for tightening or compressing the springs. This tool is commonly used when working on suspension systems, such as replacing shock absorbers, struts, or other components that require the removal or installation of coil springs. The compressor allows users to safely compress the spring, reducing tension and facilitating the disassembly or assembly of related parts. Proper usage of a coil spring compressor is essential to prevent accidents and injuries during automotive maintenance or repair tasks.

Inflating Gun

An inflating gun typically refers to a tool or device designed for inflating objects such as tires, sports balls, inflatable toys, or other inflatable items. It typically consists of a nozzle or attachment connected to a source of compressed air, often a pump or a compressed air cylinder. The purpose of an inflating gun is to provide a controlled and directed flow of air into the inflatable object, increasing its internal pressure and causing it to expand or become firm. These devices are commonly used in various applications, including automotive maintenance, sports, and recreational activities.

Locking Pliers Set

A locking pliers set typically refers to a collection of four individual locking pliers or vice grips, which are versatile hand tools used for gripping, clamping, and holding objects securely. Locking pliers have a mechanism that allows them to lock onto an object, providing a firm and adjustable grip. The set may include various types and sizes of locking pliers, such as curved jaw, long nose, or needle-nose pliers, each designed for specific tasks and applications. This set is commonly used in woodworking, metalworking, automotive repair, and various DIY projects where a strong and reliable grip is required.

Ratchet Handle with Sockets Set

A ratchet handle with sockets set typically refers to a toolkit consisting of a ratcheting handle and 13 different sockets of various sizes. The ratchet handle is a mechanical tool that allows for convenient and reversible rotation, enabling users to tighten or loosen fasteners with ease. The set includes a variety of socket sizes, each designed to fit specific nuts or bolts. This versatile toolset is commonly used in automotive, mechanical, and household applications for tasks such as repairs, maintenance, and assembly.

Torque Multiplier

A torque multiplier is a mechanical device designed to increase the torque applied to a fastener, such as a nut or bolt, by multiplying the force exerted on it. It typically consists of a gearbox with gears or other mechanisms that allow the user to apply a relatively small force while generating a much larger torque output at the tool end. This tool is commonly used in situations where high levels of torque are required for tightening or loosening large and tightly secured fasteners, such as those found in heavy machinery or industrial applications.

Tyre Inflating Gun

A Tyre Inflating Gun, often referred to as a tire inflator or air gun, is a pneumatic tool designed for inflating vehicle tires with compressed air. It typically consists of a trigger-operated nozzle connected to an air hose and is commonly used in automotive maintenance, such as at gas stations, auto repair shops, or by individuals for inflating tires at home. The gun allows precise control over the airflow and pressure, enabling users to inflate tires to the recommended levels specified by the vehicle manufacturer.

Tyre Pressure Gun

A Tyre Pressure Gun, more commonly known as a tire pressure gauge, is a handheld instrument used to measure the air pressure within a vehicle's tires. It typically consists of a pressure-sensitive mechanism, a dial or digital display, and a nozzle that can be attached to the tire's valve stem. The primary function of a tire pressure gauge is to provide an accurate reading of the air pressure in the tire, helping drivers maintain proper inflation levels for optimal vehicle performance, fuel efficiency, and safety.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs