Roasting Cylinder

$ 134.62 Original price was: $ 134.62.$ 127.89Current price is: $ 127.89.

Sand Mesh Set

$ 11.58 Original price was: $ 11.58.$ 11.00Current price is: $ 11.00.

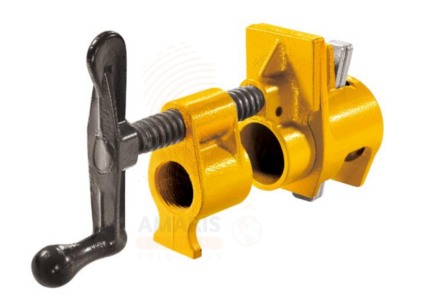

S-Clamp

$ 43.46 Original price was: $ 43.46.$ 41.29Current price is: $ 41.29.

WhatsApp Order

An S-Clamp is a versatile clamping tool shaped like the letter “S,” used for holding, positioning, or securing workpieces during various tasks such as gluing, welding, cutting, or assembly. It features dual clamping jaws that provide pressure from opposite ends, making it suitable for woodworking, metalworking, and general workshop use. Its compact design allows for use in tight or irregular spaces where other clamps may not fit, providing firm grip and alignment.

Categories: Clips & Clamps, FASTENERS

Tags: adjustable clamp, c-type clamp, gluing clamp, hand tool clamp, metal clamp, s-clamp, welding clamp, woodworking clamp, workshop clamp

Description

Table of Contents

ToggleS-Clamp

Uses

-

Woodworking Projects

o Used to hold wood pieces together during gluing or assembly.

o Maintains alignment and prevents shifting while adhesive sets. -

Metalworking and Welding

o Secures metal components in place during welding or grinding.

o Provides stability to minimize movement during high-heat processes. -

DIY and Home Repairs

o Useful for clamping objects during repairs, installations, or painting.

o Assists in hands-free operations for increased safety and precision. -

Crafts and Hobbies

o Holds small or delicate components while crafting, sanding, or assembling.

o Prevents slipping or misalignment during detailed work. -

Assembly Line Work

o Keeps parts or fixtures secured for accurate placement during fast-paced production.

o Reduces hand fatigue by maintaining constant clamping pressure. -

Machining and Drilling

o Holds materials steady on drill presses or milling machines for precision cuts.

o Prevents slipping or vibration during operation. -

Framing and Picture Hanging

o Secures corners and edges for frame assembly or repair.

o Ensures squared angles and tight joints. -

Cabinetry and Furniture Making

o Aligns panels, drawers, or frames during fabrication or repair.

o Provides consistent clamping without marring surfaces. -

Plumbing and Pipe Fitting

o Temporarily holds pipes or fittings together during alignment or bonding.

o Offers steady grip in awkward or tight spaces.

SAFETY HANDLING PRECAUTIONS

Safety Precautions

-

Inspect Clamp Before Use

o Check for cracks, bent frames, or worn threads.

o Ensure the screw mechanism moves smoothly. -

Do Not Over-Tighten

o Excessive force may damage the clamp or deform the workpiece. -

Use Appropriate Clamp Size

o Select a clamp suited to the size and weight of the materials being held. -

Keep Hands Clear

o Avoid placing fingers near jaws during tightening or positioning. -

Stable Surface Use

o Always clamp materials on a stable, flat surface to prevent tipping or slipping. -

Wear Protective Gear

o Use gloves to protect hands from pinching and safety glasses when working with power tools. -

Clean After Use

o Wipe off dust, glue, or metal shavings to maintain performance. -

Store Safely

o Hang or store clamps in a dry area to prevent rust and mechanical wear. -

Avoid Electrical Contact

o Do not use near live electrical components; metal clamps can conduct electricity.

Related products

F-Clamp

An F-clamp, also known as a bar clamp or sliding clamp, is a woodworking tool designed for holding and securing materials in place during the process of gluing, welding, or other similar tasks. It typically consists of two parallel jaws—one fixed and one movable—that can be adjusted along a bar or rail. The movable jaw can be positioned and tightened using a threaded mechanism, allowing the clamp to firmly grip and hold objects of various sizes. F-clamps are widely used in carpentry, metalworking, and other applications where a strong and adjustable clamping force is needed to ensure precision and stability during work.

Heavy Duty Pipe Clamp

A Heavy Duty Pipe Clamp is a robust fastening device designed to securely hold pipes and cylindrical workpieces during assembly, welding, gluing, or cutting operations. Constructed from high-strength materials such as cast iron or steel, it consists of adjustable jaws that grip around pipes, often using a threaded screw mechanism to apply precise clamping pressure. These clamps are essential in metalworking, plumbing, woodworking, and industrial fabrication tasks, where stability and alignment are critical. The heavy-duty variant is capable of withstanding high pressure and torque, ensuring the pipe remains stationary during demanding tasks.

HSS Twist Drill

A High-Speed Steel (HSS) Twist Drill Bits Set refers to a collection of drill bits made from high-speed steel, a type of tool steel that is designed to withstand high temperatures and offer excellent hardness and durability. Twist drill bits are characterized by their helical (spiral) grooves that help to efficiently remove material as they penetrate into the work piece. HSS drill bits are commonly used for drilling into various materials, including metals, wood, and plastics. The set typically includes a range of drill bit sizes to accommodate different drilling needs, providing versatility for various projects and applications. HSS twist drill bits are favored for their ability to maintain sharpness at elevated temperatures, making them suitable for tasks that involve high-speed drilling and heavy-duty applications.

HSS Twist Drill Bits Set

An HSS Twist Drill Bits Set typically refers to a collection of eight individual drill bits made from high-speed steel, a type of tool steel known for its durability and ability to withstand high temperatures generated during drilling. The term "twist" in "twist drill bits" refers to the helical or spiral shape of the cutting edges.

These sets usually come in a variety of sizes, allowing users to choose the appropriate bit for different drilling applications. The set may include bits with varying diameters, enabling users to drill holes of different sizes in materials like wood, metal, plastic, and other common materials.

In summary, an 8pcs HSS Twist Drill Bits Set is a versatile tool kit that provides a selection of high-quality drill bits suitable for a range of drilling tasks in various materials.

Screw Plug

A screw plug typically refers to a threaded, cylindrical device designed to be inserted into a hole or opening, primarily for the purpose of sealing, closing, or securing the opening. The threaded design allows the screw plug to be easily screwed into or out of the hole, providing a simple and effective means of closure. Screw plugs are commonly used in various applications, such as plumbing, machinery, and equipment, where they serve to prevent the leakage of liquids or gases, protect internal components, or facilitate access for maintenance and inspection.

Spring Clamp

A spring clamp is a tool designed for holding and securing objects together. It typically consists of two elongated arms joined at one end by a spring mechanism, which exerts force to keep the arms closed. The opposite ends of the arms often have gripping surfaces or jaws that can hold onto objects, allowing the clamp to be used for various applications such as woodworking, metalworking, or holding materials in place during gluing or assembly. The spring mechanism makes it easy to open and close the clamp, providing a quick and convenient way to secure items temporarily.

Staples

Staples" generally refer to fasteners used to join or secure materials together. These staples are typically U-shaped or T-shaped metal pieces designed to be driven into a surface to hold objects in place. They are commonly used in construction, carpentry, and other applications to fasten materials like wood, fabric, or wire. The staples are driven into the material using a staple gun or a similar device. The primary purpose of hardware staples is to create a secure and durable connection between materials, making them an essential tool in various building and repair tasks.

Staples for Auto Gun

Staples for auto gun are U-shaped metal fasteners specifically designed for use with pneumatic or manual staple guns. These staples are used to secure materials such as fabric, wood, wire mesh, and insulation in construction, upholstery, carpentry, and packaging applications. They are made from galvanized or stainless steel to resist rust and provide strong holding power. Available in various crown widths and leg lengths, they offer consistent penetration and fastening performance in high-speed, repetitive tasks.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs