“Smooth Operator: The Bench Plane for Perfect Finishes” 🪵✨🔧

In the world of woodworking, few tools are as timeless and satisfying to use as the bench plane. Whether you’re crafting a new piece of furniture, restoring an antique, or simply refining a surface, the bench plane is your ticket to a buttery-smooth finish that no power sander can quite match.

It’s a tool that demands patience and skill—but rewards you with unmatched precision. For woodworkers at any level, the bench plane is a must-have companion.

What Exactly is a Bench Plane? 🛠️

A bench plane is a hand tool used to shave thin layers from wood surfaces, creating smooth, flat finishes or adjusting the thickness of a piece. Its design is simple yet effective:

- A Sharp Blade (Iron) – Positioned at an angle to slice wood fibers cleanly.

- A Sole (Flat Base) – Ensures consistent contact with the workpiece.

- A Comfortable Handle – Gives you control and leverage.

From small block planes for detail work to large jointer planes for straightening edges, there’s a bench plane for every woodworking need.

Main Uses of a Bench Plane 📏

Bench planes excel at:

- Smoothing – Removing tool marks, saw ridges, or uneven surfaces.

- Flattening – Correcting warped boards or uneven panels.

- Thickness Adjustment – Trimming wood to the perfect size.

- Jointing – Creating straight, true edges for gluing boards together.

- Chamfering – Adding neat angled edges to your work.

Why Choose a Bench Plane Over Power Tools? ⚡

While electric planers and sanders are faster, they often lack the finesse of a well-tuned bench plane. Here’s why many woodworkers still reach for one:

- Quiet Operation – No motors, no noise—just the satisfying swish of steel on wood.

- Greater Control – You dictate the cut depth, pressure, and pace.

- No Dust Clouds – Shavings are cleaner and safer to manage than fine dust.

- Preserves Character – Maintains the wood’s natural beauty without over-grinding.

Pro Tips for Using a Bench Plane 💡

- Sharpness is Key – A dull blade will tear fibers instead of slicing them.

- Adjust for Fine Cuts – Small adjustments make a big difference.

- Work With the Grain – Planing against the grain can cause tear-out.

- Keep the Sole Smooth – Waxing the base reduces friction for easier strokes.

- Consistent Pressure – Apply slightly more pressure at the start, then ease off at the end of each pass.

Maintaining Your Bench Plane 🧴

- Blade Care – Sharpen regularly using a whetstone or honing guide.

- Rust Prevention – Store in a dry place and lightly oil the blade.

- Clean After Use – Wipe down to remove resin and shavings.

- Adjustments – Check and fine-tune blade alignment before each project.

Bench Plane Varieties 🔍

At Amaris Hardware Solutions, we’ve seen woodworkers use different planes for specific tasks:

- Jack Plane – All-purpose, great for general smoothing and trimming.

- Smoothing Plane – Gives that final silky surface before finishing.

- Jointer Plane – Long and ideal for truing edges and flattening large boards.

- Block Plane – Compact and perfect for smaller detail work.

Each has its own specialty, but the classic bench plane remains a universal workhorse.

Why Every Workshop Needs One 🧰

A bench plane isn’t just a tool—it’s a connection to the craft of woodworking at its purest. Using one slows you down just enough to focus on each stroke, each shaving, and each subtle improvement in the wood’s surface.

Whether you’re a seasoned carpenter or a weekend DIYer, mastering a bench plane can elevate your projects from “good” to “exceptional.” And when paired with quality sharpening tools and proper technique, it can last for decades, becoming one of those heirloom tools you pass down.

At Amaris Hardware Solutions, we believe the bench plane is one of those rare tools that blends tradition, skill, and beauty in every use. Once you experience the satisfaction of a perfectly planed surface, you’ll understand why this tool hasn’t gone out of style for centuries.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

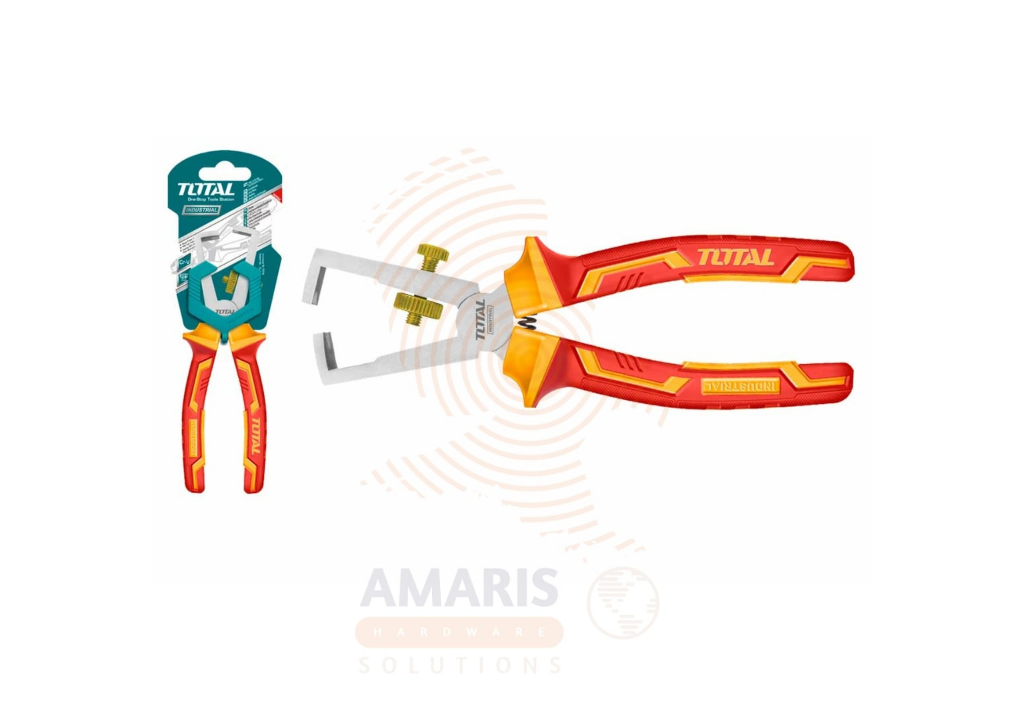

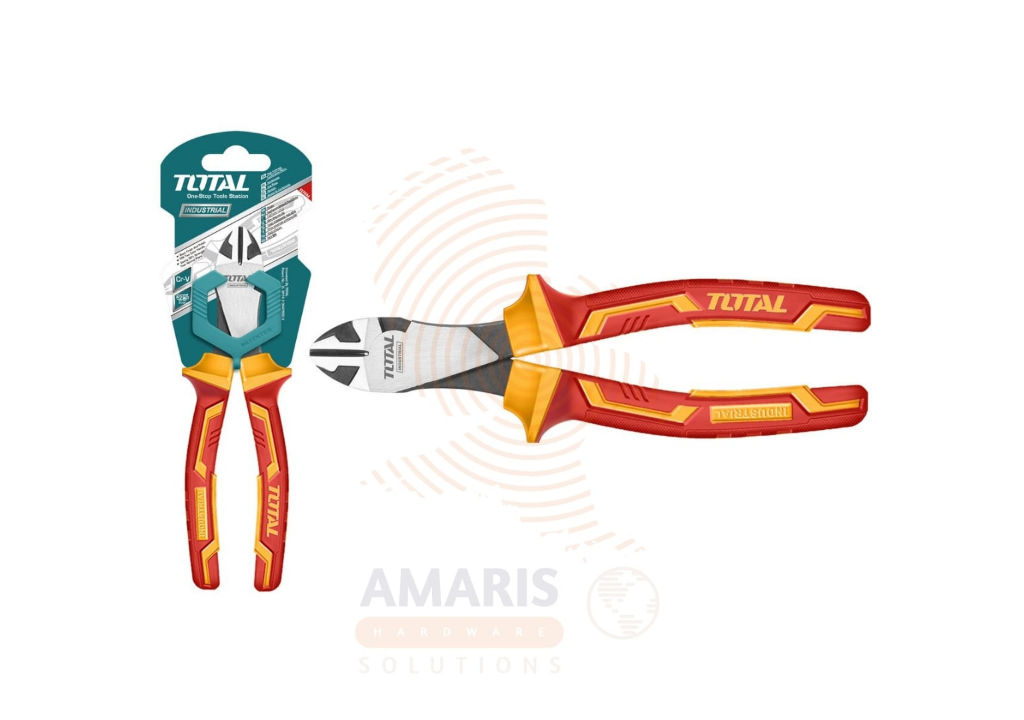

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs