Demolition Hammer

The Demolition Hammer is a powerful, heavy-duty tool designed for breaking, chipping, and demolishing concrete, masonry, tiles, and other tough materials. Equipped with a robust motor and durable hammering mechanism, it delivers high impact energy for efficient demolition work. Ideal for construction, renovation, and remodeling projects, this tool is built for both professional contractors and serious DIY enthusiasts. Its ergonomic design ensures comfort during prolonged use, while vibration reduction features minimize user fatigue.

Demolition Hammer Drill

A demolition hammer drill, often referred to as a demo hammer or breaker hammer, is a powerful handheld tool designed for heavy-duty tasks in construction and demolition. It combines the functions of a hammer and a drill to break through and remove concrete, masonry, and other hard materials. Typically featuring a pneumatic or electric power source, a demolition hammer drill delivers rapid, repetitive blows to the surface, effectively chipping away and breaking up the material. This tool is commonly used in construction, renovation, and demolition projects to facilitate the removal of old structures or the creation of openings in hard surfaces.

Diamond Cup Wheels Double Row Segmented

A Diamond Cup Wheels Double Row Segmented design is a specialized grinding tool used in various applications, primarily in the field of construction and stone processing. The term "diamond cup wheel" refers to the tool's composition, where industrial-grade diamonds are bonded to the wheel's surface to facilitate efficient material removal through abrasion.

The "double-row segmented" aspect of the cup wheel describes its segmented rim structure. The rim, or outer edge of the wheel, is divided into two rows of segments with gaps or spaces in between. Each segment contains diamond particles that contribute to the grinding or cutting action. This design enhances the wheel's durability, ensures a more consistent material removal rate, and allows for better cooling during operation.

Diamond Cup Wheels Turbo Row

A Diamond Cup Wheels Turbo Row is a specialized grinding tool used in construction and masonry for shaping, smoothing, and grinding hard materials such as concrete, stone, or other abrasive surfaces. It consists of a circular wheel with diamond-coated segments arranged in a turbo row pattern, which enhances the tool's cutting and grinding efficiency.

The term "turbo row" refers to the specific arrangement of the diamond segments on the wheel. These segments are strategically positioned in a spiral or turbo-like pattern, allowing for a more aggressive and faster material removal compared to regular cup wheels. The diamond coating on the segments ensures durability and effectiveness in grinding hard substances. Diamond cup wheels with turbo rows are commonly used in tasks like concrete surface preparation, stone shaping, and grinding applications in construction and related industries.

Diamond Cutting Blade (Dry) – Hot Press

A diamond cutting blade (dry), hot press is a specialized tool used in construction and fabrication processes for cutting hard materials such as stone, concrete, or ceramics. This type of blade is characterized by its use of diamond crystals embedded in a metal matrix on the cutting edge. The term "dry" indicates that the blade is designed to operate without the need for water or other cooling agents during the cutting process. The "hot press" method refers to the manufacturing technique where the diamond particles are bonded to the blade through a high-temperature and high-pressure process, ensuring a durable and efficient cutting tool.

Diamond Cutting Blade (Turbo) – Cold Press

A Diamond Cutting Blade (Turbo) – Cold Press is a specialized tool used in construction and masonry for cutting hard materials such as concrete, granite, marble, or other similar substances. The term "Turbo" typically refers to the design of the blade, featuring a segmented rim with narrow gullets or slots that aid in cooling and debris removal during the cutting process.

The "Cold Press" aspect indicates the manufacturing process used to create the diamond blade. In a cold press method, the diamond segments are pressed and sintered at lower temperatures, resulting in a blade with a different structure compared to hot-pressed blades. Cold press blades are known for their durability and ability to withstand high temperatures during prolonged use.

Diamond Cutting Blade(Dry) – Cold Press

A Diamond Cutting Blade(Dry) - Cold Press is a specialized tool used for cutting hard materials such as stone, concrete, or tiles without the need for water cooling. The term "dry" indicates that the blade can operate without a constant water supply, making it convenient for certain applications where water might be impractical or undesirable. "Cold press" typically refers to the manufacturing process in which diamond particles are embedded into the blade without the use of high temperatures, ensuring the integrity of the diamonds and their ability to cut effectively. This type of diamond cutting blade is designed for efficient and precise cutting in various construction and masonry projects.

Diamond Cutting Blade(Wet) – Cold Press

A Diamond Cutting Blade(Wet) - Cold Press refers to a specialized tool used for cutting hard materials such as stone, concrete, or ceramic tiles. The term "diamond" in this context refers to the use of industrial-grade diamonds embedded on the blade's edge, which provides exceptional hardness and abrasion resistance. The cutting process is typically done with water to cool the blade and minimize dust. The "cold press" aspect suggests that the cutting is performed without the application of excessive heat, ensuring precision and preventing damage to the material being cut. This type of cutting blade is commonly used in construction and masonry for achieving accurate and clean cuts in tough materials.

Diamond Grinding Wheel (Double Row)

The Diamond Grinding Wheel (Double Row) is a high-performance abrasive wheel designed for use with angle grinders and other compatible rotary tools. It features double rows of diamond segments that enhance grinding efficiency and provide a smoother finish compared to single-row wheels. This tool is specially engineered for aggressive material removal and long-lasting durability, particularly on hard surfaces like concrete, granite, stone, and masonry. The double-row segment design improves heat dissipation and helps reduce vibration, ensuring faster work with minimal chipping or gouging.

Diamond Grinding Wheel (Single Teeth)

A diamond grinding wheel (single teeth) is a specialized abrasive tool used in various industries for precision grinding and shaping of hard materials. It consists of a circular disc with a single layer of diamond grains bonded to its surface. Diamond, being one of the hardest known materials, enables the wheel to efficiently grind and cut through materials such as metals, ceramics, glass, and composites. The single teeth design implies that the abrasive material is concentrated in specific areas, allowing for precise and controlled material removal during the grinding process. Diamond grinding wheels are commonly employed in applications where high precision and durability are essential, such as in tool and die making, precision machining, and the production of intricate components.

Diamond Grinding Wheel(Turbo)

A Diamond Grinding Wheel(Turbo) is a specialized tool used in machining and abrasive processes. It consists of a circular disc with diamond particles bonded to its surface, allowing it to effectively grind and shape hard materials such as metal, stone, or concrete. The term "turbo" in this context typically refers to the design of the wheel, featuring a segmented rim with openings that help dissipate heat and improve cutting efficiency. Diamond grinding wheels are known for their exceptional hardness and durability, making them suitable for tasks that require precision and the ability to work on materials with high hardness levels.

Double – End Bits Set

A Double - End Bits Set typically refers to a collection of interchangeable tool bits designed for use with screwdrivers, power drills, or similar tools. Each bit in the set has two distinct ends with different types or sizes of tips, allowing the user to perform various tasks without needing multiple individual bits. These sets often include a variety of common bit types, such as Phillips, slotted, Torx, or hex, providing versatility for different screw and fastener types. The double-ended design allows users to flip the bit and switch between different tips easily, making it a convenient and space-saving solution for various applications.

Double – End Bits Set slotted

A Double - End Bits Set slotted is a collection of screwdriver bits featuring slotted (flathead) tips on both ends, designed for use with power drills, screwdrivers, and bit holders. These bits are typically made from durable steel alloys, offering long-lasting performance and resistance to wear. The double-ended design allows for extended use and quick flipping between ends when one becomes worn, increasing convenience and efficiency. Slotted bits are ideal for fastening or loosening screws with straight, single-groove heads commonly found in woodworking, electrical applications, and general-purpose repairs.

Dry Wall Sander

A Dry Wall Sander is a specialized tool designed for smoothing and finishing drywall surfaces. It typically consists of a flat sanding head attached to a long handle, allowing the user to reach high or wide areas. The tool is used in conjunction with sandpaper or abrasive mesh screens to remove imperfections, such as bumps, ridges, or joint compound seams, from drywall installations. Drywall sanders may be manual or powered, with some powered versions equipped with a dust collection system to minimize airborne dust during the sanding process. These tools are essential for achieving a smooth and even finish on walls and ceilings before painting or applying other wall finishes.

Dust Blowing Gun

A "dust blowing gun" typically refers to a handheld tool or device designed to blow compressed air for the purpose of cleaning dust and debris from surfaces, machinery, or other objects. It usually consists of a nozzle attached to a handle, with a trigger mechanism to release bursts of compressed air. These devices are commonly used in various industries, workshops, and households to clean delicate electronic components, computer keyboards, camera lenses, and other items where traditional cleaning methods might be impractical or ineffective. The use of compressed air helps dislodge and remove dust without causing damage to sensitive equipment.

Dust Blowing Gun – Long Nozzle

A Dust Blowing Gun - Long Nozzle is a handheld tool designed for effectively removing dust and debris from various surfaces. It typically consists of a nozzle attached to a handle or a compressed air gun. The long nozzle allows for precise and targeted airflow, making it especially useful for reaching into tight or difficult-to-access spaces where dust tends to accumulate.

These tools are commonly used in cleaning applications across industries such as automotive, electronics, woodworking, and general maintenance. The focused and high-velocity air stream generated by the long nozzle helps dislodge and remove dust from intricate machinery, electronic components, or other surfaces without causing damage. Dust blowing guns with long nozzles are valued for their versatility and efficiency in maintaining a clean and dust-free environment in a variety of settings.

Electric Hammer Drill

An electric hammer drill is a versatile power tool designed for drilling into hard materials, such as concrete, stone, or masonry. It combines the functions of a regular drill with a hammering action, allowing it to break through tough surfaces more effectively. The hammering mechanism involves rapid, short, and powerful thrusts, enhancing the drill's ability to penetrate hard materials. The electric motor powers both the rotational drilling and the hammering action, making the tool suitable for tasks that require more force than a standard drill can provide.

Electric Router

An electric router is a power tool used in woodworking and carpentry for hollowing out an area or creating a specific profile on the edge of a material, typically wood. It operates by spinning a cutting tool or bit at high speeds, allowing for precise and controlled removal of material. Electric routers are versatile tools and can be equipped with various bits to perform tasks such as shaping, grooving, trimming, and forming decorative edges. They are widely employed in both professional and DIY settings for tasks that require accurate and intricate detailing in woodworking projects.

Electric Spray Gun

An electric spray gun is a handheld device powered by electricity that utilizes a motor-driven pump or turbine to atomize liquid coatings, such as paint or varnish, into a fine mist. This fine spray is then evenly and efficiently applied to surfaces, providing a smooth and uniform finish. Electric spray guns are commonly used in various industries and DIY applications for tasks such as painting walls, furniture, automotive components, and other surfaces requiring a professional and even coating. The electric power source distinguishes them from other types of spray guns that may be powered by compressed air or other means.

Fast Charger

A fast charger is a device designed to quickly recharge compatible batteries with a voltage rating of 20 volts. The "fast" designation implies that the charger is engineered to deliver a higher charging current, allowing for a more rapid replenishment of the battery's energy capacity compared to standard chargers. This type of charger is commonly used for power tools, electronic devices, or other equipment that operates on 20V batteries, providing users with a more efficient and time-saving charging solution.

Finishing Sander

The finishing sander is a high-performance power tool designed to deliver smooth, even surfaces on wood, metal, or painted materials. Its ergonomic design allows for comfortable handling during extended use, while its powerful motor ensures consistent sanding performance. Perfect for removing minor imperfections, preparing surfaces for paint or varnish, and achieving a professional-quality finish, this tool is ideal for carpenters, woodworkers, DIY enthusiasts, and home improvement projects. The finishing sander is compatible with a variety of sanding pads and accessories, making it versatile for different applications and finishing requirements.

Forstner Bit Set

A Forstner bit set typically refers to a collection of five Forstner drill bits designed for woodworking applications. Forstner bits are specialized cutting tools used to bore flat-bottomed holes with clean and precise edges in wood. The set usually includes five bits with varying diameters, allowing users to choose the appropriate size for different projects. These bits often feature a center point for accurate positioning, two sharp outer cutting edges, and a cylindrical shape. The set is versatile and suitable for tasks like drilling holes for dowels, creating pocket holes, or countersinking screws in woodworking projects.

Forstner Bits

A Forstner bit is a specialized woodworking drill bit designed for creating flat-bottomed holes with a clean and precise finish. Unlike traditional twist drill bits, Forstner bits have a cylindrical, flat-bottomed shape with a center point and cutting edges along the circumference. These bits are commonly used when a smooth and accurately sized hole without breakthrough is required in woodworking applications, such as for drilling holes for dowels or creating recesses for hardware like hinges. Forstner bits are known for their ability to produce clean and splinter-free boreholes, making them popular among woodworkers and cabinetmakers for tasks that demand precision and aesthetics.

Forstner Drill Bits

A Forstner drill bit is a specialized cutting tool used in woodworking to create flat-bottomed holes with smooth sides. Unlike traditional twist or spade drill bits, Forstner bits are characterized by a cylindrical shape with a flat bottom and a rim that cuts the perimeter of the hole. These bits are well-suited for precision drilling tasks, such as creating boreholes for dowels or hinge cups, as they produce clean and accurate results, minimizing tear-out and splintering in the wood. Forstner drill bits are commonly used in cabinetry, furniture making, and other woodworking applications where precise and clean hole drilling is essential.

Frog Tamping Rammer

A Frog Tamping Rammer is a compact, high-impact compaction machine used in construction for compacting soil, gravel, and sand in confined or hard-to-reach areas. Unlike larger plate or roller compactors, this rammer delivers a powerful vertical force through a narrow, foot-like base (hence the name “frog”) to compact cohesive and granular soils. Commonly powered by gasoline or diesel engines, it is ideal for trench work, pipeline backfilling, foundations, road repairs, and other applications where precision and deep compaction are essential. Known for its portability and high compaction force, the frog rammer is indispensable in urban construction, civil engineering, and landscaping projects.

Gasoline Auger Machine

A gasoline auger machine is a power tool designed for drilling holes in the ground using a rotating helical screw blade, commonly known as an auger. Unlike electric or manual augers, a gasoline auger machine is powered by a gasoline engine, providing greater mobility and independence from electrical power sources. This type of machine is commonly used in construction, landscaping, and agriculture for tasks such as digging holes for fence posts, planting trees, or installing various types of foundations. The gasoline engine provides the necessary power to turn the auger bit efficiently, making it suitable for heavy-duty and remote applications where access to electricity may be limited.

Gasoline Chain Saw

A Gasoline Chain Saw is a portable, mechanical cutting tool powered by an internal combustion engine that runs on gasoline. It typically consists of a chain with teeth attached to a guide bar, driven by the engine, and is commonly used for tasks such as tree felling, limb pruning, and wood cutting. The gasoline engine provides the necessary power to drive the chain, making the chainsaw a versatile tool for various outdoor cutting applications.

Gasoline Concrete Vibrator

A gasoline concrete vibrator is a construction tool powered by a gasoline engine and designed for consolidating and compacting freshly poured concrete. It typically consists of a vibrating head or poker attached to a flexible shaft, which is connected to the engine. The vibrator is inserted into the wet concrete to eliminate air bubbles, improve the overall strength and density of the concrete, and ensure a smooth and uniform finish. The gasoline engine provides the necessary power for the vibration, making the tool versatile and suitable for use in locations where electric power may not be readily available.

Gasoline Hedge Trimmer

A gasoline hedge trimmer is a handheld gardening tool powered by a gasoline engine, designed for trimming and shaping hedges, bushes, and shrubs. It consists of a cutting blade or blades, typically reciprocating, attached to a long shaft with a handle or grip for ease of use. The gasoline engine provides the necessary power to drive the blades, offering mobility and independence from electrical outlets, making it suitable for use in outdoor settings where access to electricity may be limited. Gasoline hedge trimmers are valued for their versatility, allowing users to manicure and maintain landscaping with efficiency and precision.

Glass Drill Set Hexagonal Handle

A Glass Drill Set Hexagonal Handle typically refers to a collection of five drill bits specifically designed for drilling holes in glass surfaces. The term "hexagonal handle" indicates that the shank of each drill bit has a hexagonal (six-sided) shape, which can provide a better grip and prevent slipping when used with a compatible drill. These drill bits are specifically crafted for working with glass materials, offering precision and minimizing the risk of cracking or damaging the glass during the drilling process. The set may include different-sized bits to accommodate various hole diameters.

Glass Drill Set Straight Handle

A Glass Drill Set Straight Handle refers to a set of five drill bits specifically designed for drilling into glass surfaces. Each drill bit in the set typically has a straight handle, making it easier to grip and control during the drilling process. These drill bits are crafted with materials and designs that enhance their ability to cut through glass without causing cracks or shattering. The set may include a variety of drill bit sizes to accommodate different drilling needs and applications on glass surfaces.

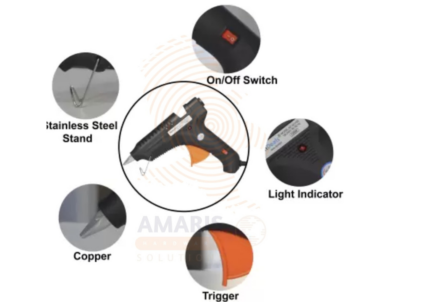

Glue Gun

A glue gun, specifically a 40-watt glue gun, is a handheld tool designed for dispensing hot melt adhesive in a controlled and precise manner. It typically consists of a heating element powered by a 40-watt electrical system, a trigger mechanism to control the adhesive flow, and a nozzle for directing the melted glue. The glue stick, usually made of thermoplastic materials, is inserted into the gun, melted by the heating element, and then extruded through the nozzle as a liquid adhesive. This versatile tool is commonly used in various DIY projects, crafts, and home repairs due to its quick and efficient bonding capabilities. The 40-watt power rating indicates the electrical power consumed by the glue gun to heat the adhesive to its melting point.

Hammer Drill

A hammer drill is a versatile power tool designed for drilling into hard materials such as concrete, stone, brick, or masonry. It combines the functionality of a regular drill with a hammering or percussive action, which helps break up and remove material more effectively. This tool is commonly used in construction and renovation projects where drilling into tough surfaces is required. The hammer drill's distinctive feature is its ability to generate rapid, short, and powerful thrusts in addition to the rotary motion, making it well-suited for challenging drilling tasks in harder materials.

Hammer Mill

A Hammer Mill is an industrial grinding machine used to crush, pulverize, shred, and reduce the size of various materials such as grains, biomass, minerals, and agricultural products. It operates by rotating hammers attached to a spinning rotor that strike the material, breaking it down into smaller pieces which pass through a screen for size control. Hammer Mills are widely used in feed production, biomass processing, recycling, and mineral processing due to their efficiency and versatility. They come in various sizes and configurations, suitable for fine to coarse grinding and are essential in agriculture, manufacturing, and energy industries.

Hand Sander

A hand sander is a handheld tool designed for sanding and smoothing various surfaces, typically wood or other materials. It is equipped with an abrasive surface, such as sandpaper, that rotates, vibrates, or moves in a circular motion when the tool is powered. Hand sanders are commonly used in woodworking and other crafting activities to remove imperfections, shape surfaces, and achieve a smooth finish on projects. They come in various types, including orbital sanders, palm sanders, and detail sanders, each serving specific purposes in the sanding process.

Hand Saw – Wood Handle

A Hand Saw - Wood Handle is a manual cutting tool designed for woodworking, featuring a blade with teeth for cutting through various materials, primarily wood. The wood handle provides a comfortable grip for the user, facilitating controlled and precise cutting motions. This type of saw is typically used for a variety of woodworking tasks, such as crosscutting, ripping, and shaping wood. The wooden handle not only serves as a functional component for holding and maneuvering the saw but also adds a traditional and aesthetic element to the tool.

Heat Gun

A heat gun is a versatile handheld tool that produces a stream of hot air when activated. Typically used for applications such as paint stripping, soldering, shrinking heat shrink tubing, bending plastic pipes, and thawing frozen pipes, a heat gun operates by passing electric current through a heating element, which then releases hot air through a nozzle. Its temperature and airflow settings can be adjusted to suit various tasks, making it a valuable tool in a range of industries and DIY projects.

High pressure washer

A High pressure washer, rated at 2000 watts, is a powerful cleaning device designed for various applications, such as cleaning surfaces, vehicles, outdoor spaces, and more. The "2000W" indicates the power consumption or wattage of the washer, suggesting a robust motor that can generate high water pressure for effective cleaning. This type of pressure washer is likely to deliver strong water jets, making it suitable for tackling tough dirt, grime, and stains in residential or industrial settings. The versatility and efficiency of a 2000W high-pressure washer make it a popular choice for tasks that demand substantial cleaning power.

High Pressure Washer Heavy Duty Packed in a Case

The High Pressure Washer Heavy Duty Packed in a Case is designed for efficient and powerful cleaning tasks. Ideal for both residential and commercial use, this washer delivers high water pressure to remove dirt, grime, and stains from various surfaces including driveways, vehicles, patios, and outdoor equipment. The compact case ensures easy storage and portability, while robust construction guarantees long-lasting performance. Equipped with adjustable nozzles and user-friendly controls, it provides versatility and precision for a wide range of cleaning applications.

Acrylic Sealants

Acrylic Sealants Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Duct Tape

Duct Tape Electrical Tape

Electrical Tape Epoxy & Resins

Epoxy & Resins Masking Tape

Masking Tape

Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators

Tire Inflators Vehicle Lighting

Vehicle Lighting Oil & Lubricants

Oil & Lubricants

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Flooring (Tiles, Wood, Laminate)

Flooring (Tiles, Wood, Laminate) Lumber & Plywood

Lumber & Plywood Paints, Primers & Coatings

Paints, Primers & Coatings Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials

Circuit Breakers

Circuit Breakers Electrical Cables & Wires

Electrical Cables & Wires Switches & Sockets

Switches & Sockets Fuses & Relays

Fuses & Relays Connectors & Terminals

Connectors & Terminals Electrical Boxes & Panels

Electrical Boxes & Panels Conduit & Fittings

Conduit & Fittings Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Extension Cords & Power Strips

Extension Cords & Power Strips

Anchors

Anchors Bolts

Bolts Clips & Clamps

Clips & Clamps Screws

Screws Nuts

Nuts Washers

Washers Rivets

Rivets Nails

Nails Threaded Rods

Threaded Rods

Hammers

Hammers Measuring Tools (Tapes, Levels, Calipers)

Measuring Tools (Tapes, Levels, Calipers) Screwdrivers

Screwdrivers Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Wrenches & Spanners

Wrenches & Spanners

Power Tool Accessories (Blades, Bits, Discs)

Power Tool Accessories (Blades, Bits, Discs) Rotary Tools

Rotary Tools Saws (Circular, Jigsaw, Reciprocating)

Saws (Circular, Jigsaw, Reciprocating) Drills & Drivers

Drills & Drivers Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Nail Guns

Nail Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers

Pipes & Fittings (PVC, Copper, PEX)

Pipes & Fittings (PVC, Copper, PEX) Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing Valves & Taps

Valves & Taps Water Heaters

Water Heaters Drainage Systems

Drainage Systems Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Respirators & Masks

Respirators & Masks Safety Glasses

Safety Glasses Safes

Safes Security Cameras

Security Cameras Gloves

Gloves Helmets

Helmets Ear Protection

Ear Protection Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems (Hoses, Sprinklers, Nozzles)

Watering Systems (Hoses, Sprinklers, Nozzles)

Interior Paints

Interior Paints Paint Brushes & Rollers

Paint Brushes & Rollers Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Exterior Paints

Exterior Paints Spray Paints

Spray Paints Primers & Undercoats

Primers & Undercoats Varnishes & Stains

Varnishes & Stains

Gaskets & Seals

Gaskets & Seals Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys

HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Refrigerants

Refrigerants Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Fans & Blowers

Fans & Blowers

Pegboards & Hooks

Pegboards & Hooks Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Welding Accessories (Clamps, Brushes)

Welding Accessories (Clamps, Brushes) Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Soldering Irons & Stations

Soldering Irons & Stations Flux & Solder Wire

Flux & Solder Wire

Generator Accessories

Generator Accessories Inverters

Inverters Portable Generators

Portable Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Diesel & Gasoline Generators

Diesel & Gasoline Generators

Transport Equipment: Carts, Dollies, and Hand Trucks

Transport Equipment: Carts, Dollies, and Hand Trucks Storage Solutions: Pallets, Racks, and Containers

Storage Solutions: Pallets, Racks, and Containers Lifting Equipment: Hoists, Cranes, and Jacks

Lifting Equipment: Hoists, Cranes, and Jacks Conveyors & Accessories: Belts & Rollers

Conveyors & Accessories: Belts & Rollers

Office Chairs

Office Chairs