“Angle Grinder – Variable Speed” has been added to your cart. View cart

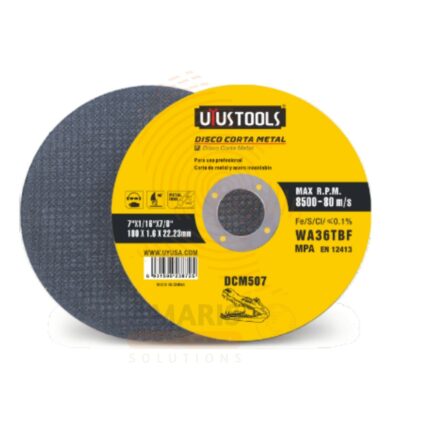

Fibre Strengthened Resin Cutting Wheel

$3,640.00 Original price was: $3,640.00.$3,140.00Current price is: $3,140.00.

Floor Jack 2T

$9,950.00 Original price was: $9,950.00.$8,950.00Current price is: $8,950.00.

Finishing Sander

$9,850.00 Original price was: $9,850.00.$8,850.00Current price is: $8,850.00.

WhatsApp Order

This is a type of power finishing sander used for finishing tasks, typically after the initial sanding or shaping has been done. Finishing sanders are designed to provide a smooth and fine surface finish.

- 115 x 229 mm: These dimensions refer to the size of the sanding surface or sanding pad on the sander. In this case, the sanding pad is 115 millimeters in width and 229 millimeters in length. The size of the sanding pad determines the coverage area and is relevant for the type and size of work pieces the sander is suitable for.

- 330W: This indicates the power of the sander in watts. The power of the sander influences its performance, especially when dealing with tougher materials or larger projects. A 330W finishing sander is likely to be suitable for a range of finishing tasks.

SKU:

AHS77231

Category: Grinders & Sanders

Description

Finishing Sander Uses

- Smoothing Wood Surfaces: One of the primary uses of a finishing sander is to smooth the surfaces of wooden pieces. It is effective in removing fine imperfections, scratches, and unevenness left by coarser sanding or shaping tools.

- Preparing Surfaces for Finishing: Before applying finishes such as paint, varnish, or stain, it’s essential to have a smooth surface. A finishing sander helps in preparing the wood by creating a uniform and smooth texture, ensuring a better finish for coatings.

- Refinishing Furniture: When restoring or refinishing old furniture, a finishing sander is valuable for stripping away old finishes, smoothing surfaces, and preparing the furniture for a new coat of paint or stain.

- Polishing and Smoothing Edges: The compact size and precise control of a finishing sander make it suitable for smoothing and rounding the edges of wood pieces. This is particularly important for creating a polished and professional look in woodworking projects.

- Fine Detailing: Finishing sanders are excellent for detailed work, such as sanding intricate designs, carvings, or moldings where precision is crucial. The fine-grit sandpaper used with a finishing sander allows for intricate detail without removing too much material.

- Craft and Hobby Projects: Whether you’re working on smaller craft projects or DIY home improvement tasks, a finishing sander is often the ideal tool for achieving a polished and refined finish on various materials.

- Sanding Between Coats: In between coats of paint or finish, a finishing sander can be used to lightly sand the surface, providing better adhesion for the subsequent coats and ensuring a smoother final result.

Reviews (0)

Be the first to review “Finishing Sander” Cancel reply

SAFETY & HANDLING MEASURES

Safety Precautions

- Wear Safety Goggles & Dust Mask – Protect from fine particles and debris

- Check Sandpaper – Ensure it’s properly attached and not worn

- Secure Workpiece – Use clamps to prevent movement

- Start at Low Speed – For better control on delicate surfaces

- Disconnect Power – Unplug/remove battery before changing paper

Storage Procedures

- Clean After Use – Remove dust from pad and vents

- Store Sandpaper Flat – Prevent curling or damage

- Hang or Case Storage – Protects sander from dust and drops

- Battery Care (if cordless) – Remove and store at 30–50% charge

Critical Warnings

- NEVER operate without sandpaper

- NEVER press too hard—let the sander do the work

- NEVER use damaged or clogged sandpaper

PRODUCT SPECIFICATION

Voltage: 220V/50Hz

Orbital speed: 14000 RPM

Input power: 320W

1 pair carbon brush

3pcs sanding disc

1pc user manual

Available with different specifications:

Including:

Orbital speed: 10000 RPM

Input power: 330W

Related products

2 in 1 Mini Drill & Die Grinder

A mini die grinder is a small, handheld power tool designed for precision grinding, polishing, and shaping of materials such as metal, plastic, or wood. It typically features a compact and lightweight design, making it easy to handle and maneuver in tight spaces. Mini die grinders are commonly used in various industries, including metalworking and automotive, for tasks that require detailed and intricate work. They are equipped with a small grinding wheel or abrasive attachment, driven by a motor, allowing users to achieve precise and controlled material removal.

Angle Grinder – Variable Speed

A variable speed selector cordless angle grinder is a portable power tool designed for cutting, grinding, and polishing tasks. Unlike traditional angle grinders, this tool is equipped with a variable speed control feature, allowing the user to adjust the rotational speed of the grinding wheel or cutting disc according to the specific requirements of the task at hand. The cordless design implies that the tool operates on rechargeable batteries, providing the user with greater mobility and flexibility in various work environments. This type of angle grinder is versatile and suitable for a range of applications in construction, metalworking, and other related industries.

Bench Grinder

A bench grinder is a power tool that typically consists of two rotating abrasive wheels mounted on a spindle. The wheels can perform various tasks, such as sharpening, shaping, grinding, and polishing metal or other materials. The 350W in "Bench Grinder 350W" refers to the power of the grinder, with 350 watts being the electrical power consumption or output of the motor. This type of bench grinder is suitable for light to moderate-duty tasks, making it a versatile tool for home workshops, DIY projects, and small-scale metalworking applications.

Cup Wire Brush with Nut -Metric

- Cup Wire Brush: A cup wire brush is a type of brush with bristles (wires) arranged in a cup-shaped configuration. These brushes are commonly used for cleaning, deburring, and surface preparation in various applications. The cup shape allows for effective cleaning in concave and irregular surfaces.

- Nut - Metric: A nut in the context of hardware typically refers to a type of fastener with a threaded hole. The term "Metric" indicates that the nut follows metric system standards, which means it uses metric measurements for its dimensions. In the metric system, measurements are based on units such as millimeters and meters.

Die Grinder

A die grinder is a handheld power tool used for grinding, polishing, honing, or machining materials such as metal, plastic, or wood. It typically features a rotating spindle with a collet or chuck that holds various types of grinding or cutting attachments. Die grinders are versatile and commonly used in metalworking, construction, and fabrication industries for precision tasks that require intricate shaping, detailing, or finishing. They are compact, lightweight, and easy to maneuver, making them suitable for tasks in tight spaces or on small surfaces

Straight Type Flap Disc

A straight type flap disc is a specialized abrasive tool used in metalworking and fabrication. It typically consists of a flat, circular disc with overlapping abrasive flaps attached radially around its perimeter. These flaps are made of abrasive material, such as sandpaper or abrasive cloth, and are arranged in a straight or parallel configuration.

The straight type flap disc is designed for use with angle grinders and similar power tools. It is commonly used for grinding, blending, and finishing applications on various metal surfaces. The abrasive flaps on the disc provide a versatile and consistent abrasive action, allowing for effective material removal and surface preparation. The straight configuration of the flaps ensures a uniform grinding surface, making it suitable for tasks that require precision and control.

Overall, a straight type flap disc is a valuable tool in metalworking for tasks ranging from heavy material removal to finer surface finishing, offering efficiency and versatility in a single abrasive accessory.

Total Angle Grinder

An angle grinder is a versatile handheld power tool commonly used in construction, metalworking, and other applications. It typically features a motor-driven rotating disc, known as a grinding wheel or abrasive disc, which can be replaced with various attachments for tasks such as grinding, cutting, polishing, and sanding. The tool's design allows for the manipulation of the grinding wheel at different angles, providing flexibility and precision in a variety of tasks. Angle grinders are valued for their efficiency and ability to handle diverse materials, making them an essential tool in many industries and DIY projects.

Wet Diamond Disc

A wet diamond disc refers to a cutting or grinding tool that is equipped with diamond abrasive particles and designed to be used with water as a cooling and lubricating agent during the cutting or grinding process. Diamond is an extremely hard and durable material, making it ideal for cutting or shaping hard substances such as stone, ceramics, glass, and certain metals.

The term "wet" indicates that these diamond discs are meant to be used with water to reduce friction and heat generated during the cutting or grinding operation. Water helps to dissipate heat, prevent the diamond particles from overheating, and prolong the life of the diamond disc. Additionally, the water helps to flush away debris and keep the work surface and the diamond blade clean, resulting in smoother and more precise cuts.

Wet diamond discs are commonly used in various industries, including construction, masonry, and lapidary work, where precision cutting or grinding is essential. They are available in different sizes and configurations to suit specific applications and cutting requirements.

Acrylic Sealants

Acrylic Sealants Adhesive Application Tools

Adhesive Application Tools Construction Adhesives

Construction Adhesives Double-Sided Tape

Double-Sided Tape Masking Tape

Masking Tape Epoxy & Resins

Epoxy & Resins Duct Tape

Duct Tape Electrical Tape

Electrical Tape

Auto Body Repair Tools

Auto Body Repair Tools Automotive Wrenches & Socket Sets

Automotive Wrenches & Socket Sets Battery Chargers & Jump Starters

Battery Chargers & Jump Starters Car Jacks & Stands

Car Jacks & Stands Car Wash & Detailing Products

Car Wash & Detailing Products Diagnostic Tools

Diagnostic Tools Tire Inflators & Wheel Tools

Tire Inflators & Wheel Tools Oil & Lubricants

Oil & Lubricants Vehicle Lighting

Vehicle Lighting Suspension Tools

Suspension Tools Vehicle Maintenance Tools

Vehicle Maintenance Tools

Adhesives & Sealants

Adhesives & Sealants Bricks & Blocks

Bricks & Blocks Cement & Concrete

Cement & Concrete Drywall & Plaster

Drywall & Plaster Insulation Materials

Insulation Materials Roofing Materials

Roofing Materials Paints, Primers & Coatings

Paints, Primers & Coatings Marking & Layout Tools

Marking & Layout Tools Quarry Machinery

Quarry Machinery

Electric Motors

Electric Motors Electrical Boxes & Panels

Electrical Boxes & Panels Electrical Cables & Wires

Electrical Cables & Wires Extension Cords & Power Strips

Extension Cords & Power Strips Fuses & Relays

Fuses & Relays Lighting Fixtures & Bulbs

Lighting Fixtures & Bulbs Conduit & Fittings

Conduit & Fittings Cable Management

Cable Management Measuring & Test Equipment

Measuring & Test Equipment Circuit Breakers

Circuit Breakers Connectors & Terminals

Connectors & Terminals Switches & Sockets

Switches & Sockets

Screws

Screws Bolts

Bolts Nuts

Nuts Washers

Washers Rivets & Riveter

Rivets & Riveter Anchors

Anchors Nails

Nails Threaded Rods

Threaded Rods Clips & Clamps

Clips & Clamps

Garden Fencing

Garden Fencing Garden Furniture Hardware

Garden Furniture Hardware Agricultural Machinery

Agricultural Machinery Lawn Mowers

Lawn Mowers Trimmers & Edgers

Trimmers & Edgers Shovels & Spades

Shovels & Spades Rakes & Hoes

Rakes & Hoes Pruning Shears & Loppers

Pruning Shears & Loppers Watering Systems

Watering Systems Digging Equipment

Digging Equipment Pond Equipment

Pond Equipment

Generator Accessories

Generator Accessories Inverters

Inverters Diesel & Gasoline Generators

Diesel & Gasoline Generators Power Inverters

Power Inverters Transfer Switches

Transfer Switches Portable Generators

Portable Generators Air Compressor

Air Compressor Pressure Washers

Pressure Washers Water Pumps

Water Pumps

Fastening Tools

Fastening Tools Files & Rasps

Files & Rasps Glass working Tools

Glass working Tools Hammers

Hammers Hand Tool Accessories

Hand Tool Accessories Screwdrivers

Screwdrivers Wrenches & Spanners

Wrenches & Spanners Pliers & Cutters

Pliers & Cutters Saws & Blades

Saws & Blades Measuring Tools

Measuring Tools Chisels & Punches

Chisels & Punches Allen Keys & Hex Keys

Allen Keys & Hex Keys Ratchets & Socket Sets

Ratchets & Socket Sets Drilling & Tapping Tools

Drilling & Tapping Tools Pry Bars & Demolition Tools

Pry Bars & Demolition Tools Pulling & Extraction Tools

Pulling & Extraction Tools Punching & Perforating Tools

Punching & Perforating Tools Scrapers & Abrasive Tools

Scrapers & Abrasive Tools Utility Knives

Utility Knives Woodworking Tools

Woodworking Tools Clamps & Vises

Clamps & Vises

Hinges & Latches

Hinges & Latches Hooks & Brackets

Hooks & Brackets Door Handles & Locks

Door Handles & Locks Drawer Slides & Cabinet Hardware

Drawer Slides & Cabinet Hardware Window Hardware

Window Hardware Chains & Cables

Chains & Cables Casters & Wheels

Casters & Wheels Shelving & Storage Systems

Shelving & Storage Systems Cutting Tools

Cutting Tools

Fans & Blowers

Fans & Blowers HVAC Filters

HVAC Filters Insulation for HVAC

Insulation for HVAC Air Conditioners

Air Conditioners Ventilation Ducts & Fittings

Ventilation Ducts & Fittings Thermostats & Controllers

Thermostats & Controllers Refrigerants

Refrigerants

Food Processing Machinery

Food Processing Machinery Gaskets & Seals

Gaskets & Seals Harvesting Equipment

Harvesting Equipment Hydraulic Fittings

Hydraulic Fittings Industrial Fasteners

Industrial Fasteners Industrial Hoses

Industrial Hoses Bearings & Bushings

Bearings & Bushings Belts & Pulleys

Belts & Pulleys Lubricants & Greases

Lubricants & Greases Metal Sheets & Bars

Metal Sheets & Bars Agricultural Processing Machinery

Agricultural Processing Machinery Poultry Processing Equipment

Poultry Processing Equipment

Lifting Equipment

Lifting Equipment Transport Equipment

Transport Equipment Storage Solutions

Storage Solutions Conveyors and Accessories

Conveyors and Accessories Construction Machinery

Construction Machinery Screening Equipment

Screening Equipment Heavy Machinery

Heavy Machinery

Paint Brushes & Rollers

Paint Brushes & Rollers Paint Sprayers & Accessories

Paint Sprayers & Accessories Paint Strippers & Thinners

Paint Strippers & Thinners Paint Trays & Accessories

Paint Trays & Accessories Primers & Undercoats

Primers & Undercoats Interior Paints

Interior Paints Exterior Paints

Exterior Paints Varnishes & Stains

Varnishes & Stains Spray Paints

Spray Paints

Pipes & Fittings

Pipes & Fittings Plumbing Tools

Plumbing Tools Pumps & Motors

Pumps & Motors Valves & Taps

Valves & Taps Faucets & Fixtures

Faucets & Fixtures Hoses & Tubing

Hoses & Tubing Water Heaters

Water Heaters Drainage Systems

Drainage Systems Sealants & Adhesives for Plumbing

Sealants & Adhesives for Plumbing

Nail Guns

Nail Guns Outdoor Power Equipment

Outdoor Power Equipment Planers or Woodworking Power Tools

Planers or Woodworking Power Tools Pneumatic Tool

Pneumatic Tool Power Tool Accessories

Power Tool Accessories Drills & Drivers

Drills & Drivers Saws

Saws Grinders & Sanders

Grinders & Sanders Heat Guns

Heat Guns Impact Wrenches

Impact Wrenches Batteries & Chargers

Batteries & Chargers Construction Power Tools

Construction Power Tools Cutting Tools

Cutting Tools Demolition & Breaking Tools

Demolition & Breaking Tools Router

Router Woodworking Machinery

Woodworking Machinery

Safes

Safes Security Cameras

Security Cameras Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Fire Safety Equipment

Fire Safety Equipment Locks & Padlocks

Locks & Padlocks Motion Sensors & Alarms

Motion Sensors & Alarms

Shelving Units

Shelving Units Storage Bins & Containers

Storage Bins & Containers Toolboxes & Tool Chests

Toolboxes & Tool Chests Pegboards & Hooks

Pegboards & Hooks Workbenches

Workbenches Drawer Organizers

Drawer Organizers Labeling Supplies

Labeling Supplies

Flux & Solder Wire

Flux & Solder Wire Soldering Irons & Stations

Soldering Irons & Stations Welding Accessories

Welding Accessories Welding Electrodes & Rods

Welding Electrodes & Rods Welding Helmets & Gloves

Welding Helmets & Gloves Welding Machines

Welding Machines Welding Safety Equipment

Welding Safety Equipment Gas Equipment – Regulators & Gauges

Gas Equipment – Regulators & Gauges

Reviews

There are no reviews yet.